Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

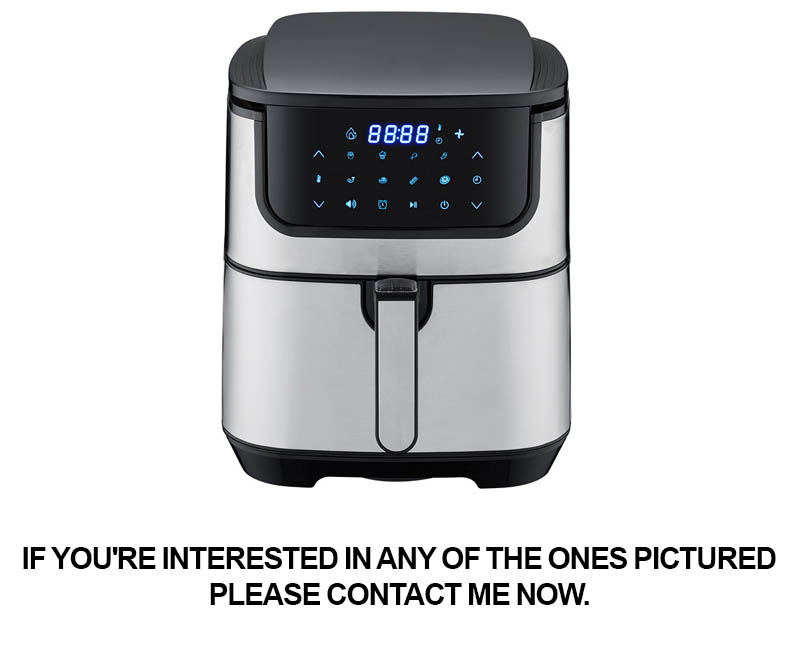

As the culinary landscape evolves, so does the technology behind kitchen appliances. One such innovation that has sparked a revolution in the commercial kitchen sector is the air fryer. These compact, efficient devices have not only changed the way chefs prepare food but have also influenced consumer preferences and market trends. In this exploration, we delve into the innovative designs and features of modern commercial air fryers, the impact they have on health and sustainability, the intricate production process, the rigorous quality control and safety standards, the role of technology in their manufacturing, case studies of successful brands, and the future outlook for commercial air fryer factories.

The commercial air fryer industry has witnessed a meteoric rise, transforming the landscape of the kitchen appliance market. These innovative cooking devices, once a niche product, have now become a staple in commercial kitchens worldwide. The surge in demand has spurred the establishment and expansion of commercial air fryer factories, each vying to be at the forefront of this culinary revolution.

As health-conscious consumers seek out healthier cooking alternatives, the air fryer has stepped into the spotlight. By using hot air to circulate around food, these appliances achieve crispy results with a fraction of the oil traditionally used in frying. This not only makes them a favorite among fitness enthusiasts but also a game-changer for chefs and restaurateurs looking to offer patrons healthier fare.

The rise of commercial air fryer factories is a testament to the industry’s adaptability and innovation. These factories are equipped with state-of-the-art technology to produce air fryers that are not only efficient but also durable. The production process involves meticulous craftsmanship, from the selection of high-quality materials to the assembly of intricate components.

One of the key factors driving the growth of commercial air fryer factories is the increasing popularity of fast-casual dining. Quick-service restaurants are constantly seeking ways to enhance their menu offerings while maintaining speed and efficiency. Air fryers allow these establishments to offer a variety of fried foods with a lighter footprint, appealing to a broad customer base.

Moreover, the versatility of commercial air fryers is undeniable. They can be used to cook a wide range of dishes, from crispy French fries and chicken wings to even desserts like beignets and churros. This flexibility has made them a must-have in many commercial kitchens, from small cafes to bustling food trucks.

As the demand for commercial air fryers continues to soar, these factories are investing in research and development to push the boundaries of what air fryers can do. New models are emerging with advanced features like programmable settings, temperature control, and even self-cleaning capabilities. These innovations not only make the appliances more user-friendly but also more appealing to businesses looking to streamline their operations.

The production process at these factories is a blend of art and science. Each air fryer is crafted with precision, ensuring that it meets the stringent quality standards required in the commercial kitchen environment. From the initial design phase to the final quality check, every step is carefully monitored to guarantee that the end product is reliable and efficient.

Safety is another critical aspect that commercial air fryer factories take very seriously. These appliances are designed to minimize the risk of accidents, with features like cool-touch exteriors and automatic shut-off mechanisms. The manufacturing process also adheres to strict safety protocols, ensuring that every air fryer that leaves the factory is a safe and secure investment.

The global market for commercial air fryers is expanding rapidly, with new markets emerging in regions like Asia and South America. As these factories expand their reach, they are also focusing on customization to cater to the specific needs of different markets. This could mean adapting to local power supply standards or incorporating regional flavors into their product line.

In the world of commercial air fryer factories, sustainability is also a key concern. With the growing awareness of environmental issues, these factories are exploring eco-friendly materials and manufacturing practices. This not only helps reduce their carbon footprint but also aligns with the values of many consumers and businesses alike.

As the commercial air fryer industry continues to evolve, these factories are at the heart of the action. They are not just producing appliances; they are shaping the future of foodservice. With a focus on innovation, quality, and sustainability, commercial air fryer factories are setting the stage for a healthier, more efficient, and delicious culinary landscape.

Commercial air fryers have become the talk of the town, and for good reason. These kitchen gadgets have been revolutionizing the way we cook, offering a healthier alternative to traditional deep-frying. The buzz around these devices is not just a fleeting trend; it’s a testament to the technological advancements and consumer demand for healthier, more efficient cooking methods.

From professional kitchens to home chefs, the demand for commercial air fryers has surged. These appliances use rapid air circulation to achieve crispy, golden results without the excessive oil that traditional frying requires. This innovative approach has sparked a wave of interest, as health-conscious consumers seek out ways to enjoy their favorite fried foods with a lighter footprint.

The convenience factor cannot be overstated. Commercial air fryers are designed for quick and easy cooking, making them a favorite among busy individuals and families. With minimal cleanup and the ability to cook a variety of foods, from vegetables to meats, these appliances have become a staple in many households. The versatility of these devices has also contributed to their popularity, as they can handle everything from crispy French fries to juicy chicken wings.

One of the main reasons for the buzz around commercial air fryers is their health benefits. By reducing the amount of oil used in cooking, these appliances help lower the calorie count and fat content of fried foods. This shift towards healthier cooking methods is a direct response to the growing public health concerns regarding obesity and heart disease. The fact that commercial air fryers can produce deliciously crispy food with less oil is a compelling reason for consumers to embrace them.

The technology behind commercial air fryers is another contributing factor to their popularity. These appliances use a process called “rapid air technology,” which circulates hot air around the food at high speeds. This method creates a crispy outer layer while keeping the inside moist and tender. The result is a fried food experience that is almost indistinguishable from traditional frying, but with significantly less fat.

Another aspect of the buzz surrounding commercial air fryers is the environmental impact. By using less oil, these appliances contribute to reduced waste and a lower carbon footprint. In a world increasingly aware of climate change and its effects, the sustainability aspect of commercial air fryers is a strong selling point.

The culinary world has also taken notice of the commercial air fryer’s potential. Chefs and food enthusiasts are experimenting with new recipes and cooking techniques, pushing the boundaries of what can be achieved with these appliances. From gourmet dishes to traditional fare, the possibilities seem endless, and this creativity is feeding the excitement around commercial air fryers.

The integration of smart technology in commercial air fryers has also added to the buzz. Many models now come with programmable settings, timers, and even Bluetooth connectivity, allowing users to control their appliances remotely. This level of convenience and connectivity is something that modern consumers appreciate, making commercial air fryers not just a cooking tool but also a smart appliance.

As the market for commercial air fryers continues to grow, so does the competition. Brands are constantly innovating, offering a wide range of features and capabilities. This has led to a diverse marketplace, where consumers can find an air fryer that fits their specific needs and preferences.

The rise of commercial air fryers is also a reflection of the broader shift towards healthier lifestyles. People are becoming more aware of the importance of nutrition and the impact of their diet on their overall well-being. The ability to enjoy their favorite fried foods without the guilt is a powerful draw for many.

In conclusion, the buzz around commercial air fryers is well-deserved. They offer a healthier, more convenient, and environmentally friendly alternative to traditional frying methods. As technology continues to evolve, these appliances are likely to become even more sophisticated, further solidifying their place in the kitchen appliance industry.

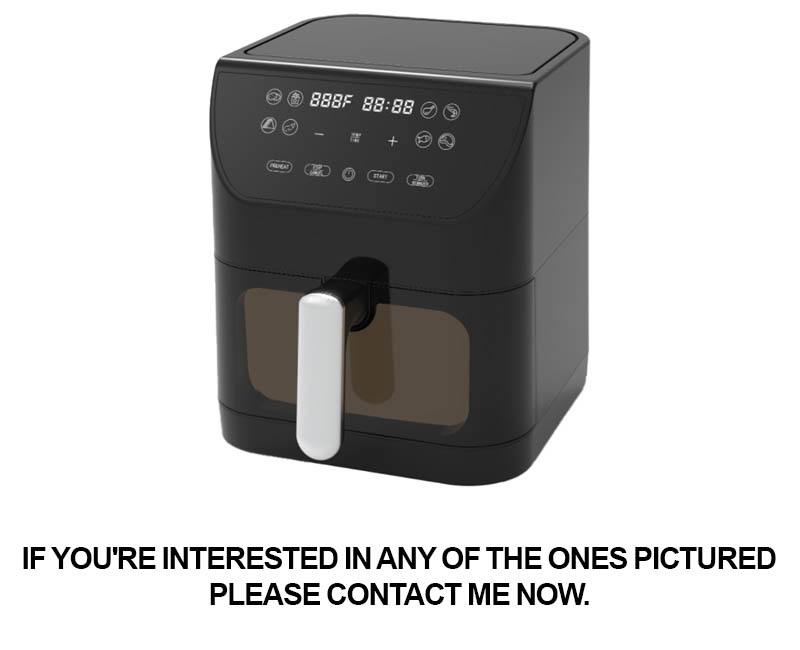

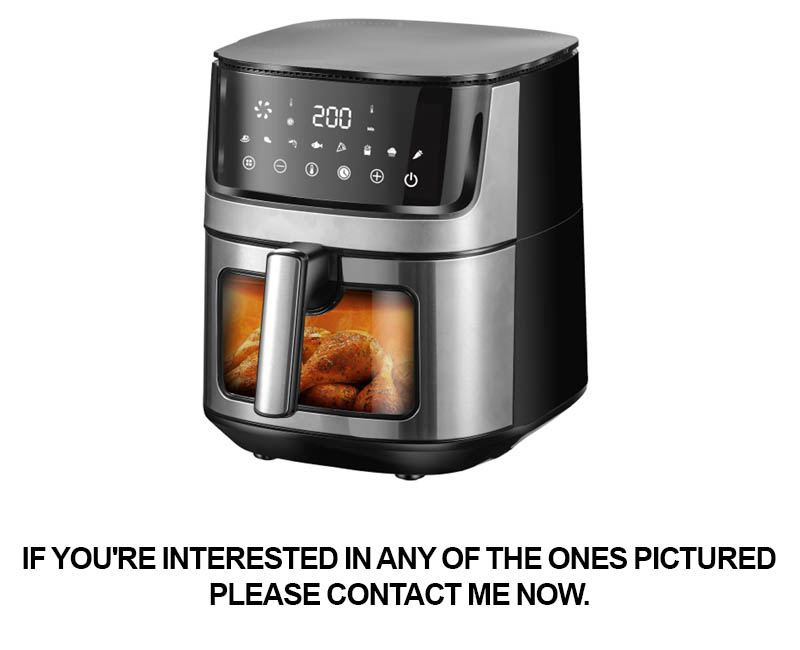

Commercial air fryers have transcended their humble beginnings and evolved into marvels of modern kitchen technology. These appliances are no longer just your average countertop gadgets; they have transformed into sophisticated machines brimming with innovative designs and features that cater to the demands of commercial kitchens. Here’s a delve into some of the standout innovations and features that set modern commercial air fryers apart.

Capacity and Versatility – Modern commercial air fryers are engineered to handle high-volume cooking, making them a favorite in restaurants and catering services. These units often come with large baskets and variable settings that allow for cooking a variety of foods from crispy fries to juicy chicken, all in one go.

Energy Efficiency – A key feature of today’s commercial air fryers is their ability to cook food with minimal energy use. These fryers utilize a convection heating system that circulates hot air around the food, reducing the need for large quantities of oil and decreasing energy consumption compared to traditional fryers.

Smart Controls and Programming – Many commercial air fryers now offer digital control panels that allow for precise temperature and time settings. These smart controls make it easy for chefs to program specific recipes, ensuring consistent and uniform results every time. Some models even include features like automatic shut-off and timers, enhancing safety and convenience.

Temperature Control – Consistency in temperature is crucial in commercial kitchens, and modern air fryers deliver with their precise temperature control capabilities. These units often come with adjustable settings, allowing for a range of cooking temperatures to cater to different types of foods and recipes.

Eco-Friendly Cooking – One of the most notable features of commercial air fryers is their eco-friendliness. With less oil needed and a lower carbon footprint compared to traditional deep fryers, these appliances are a hit with businesses looking to adopt greener practices and appeal to health-conscious customers.

Safety Features – Safety is paramount in commercial kitchens, and modern air fryers come equipped with multiple safety features. From cool-touch exteriors to automatic cool-down modes, these units are designed to minimize the risk of accidents. Some even include safety interlocks that prevent the unit from operating if the door is open.

Easy Cleaning and Maintenance – Cleaning up after a long day in the kitchen is a task no one enjoys, but modern commercial air fryers have made it easier. Non-stick interiors, removable parts, and baskets that can be cleaned in the dishwasher contribute to a more straightforward cleaning process.

Customizable Design – Knowing the importance of brand identity and kitchen aesthetics, commercial air fryer manufacturers have started to offer customizable designs. From stainless steel finishes to branded logos, these fryers can be tailored to match the aesthetic of any commercial kitchen.

Multiple Cooking Modes – To cater to diverse menus, commercial air fryers often come with multiple cooking modes. These include roast, bake, reheat, and defrost functions, making them versatile enough to handle a variety of cooking tasks.

User-Friendly Interface – The interface of a commercial air fryer is just as important as its performance. Modern units feature intuitive interfaces that make it easy for chefs to navigate through the various settings and cooking programs without any hassle.

In summary, the design and features of modern commercial air fryers have revolutionized the way kitchens operate. They combine efficiency, safety, and environmental consciousness with a host of user-friendly innovations that make them an essential tool in the commercial kitchen arsenal.

The commercial air fryer sector has witnessed a surge in popularity, driven by evolving market trends and shifting consumer preferences. Here’s a closer look at the dynamics shaping this space:

Modern consumers are increasingly health-conscious, seeking cooking methods that minimize oil usage without compromising on taste. This shift has led to a significant demand for air fryers, which use hot air to circulate around food, creating a crispy outer layer with minimal oil. The market has responded by offering a variety of air fryers that cater to this growing trend.

Energy efficiency is another key factor influencing the commercial air fryer market. With rising energy costs and environmental concerns, businesses are looking for appliances that not only save money but also reduce their carbon footprint. Air fryers, being more energy-efficient than traditional deep fryers, have become a preferred choice for commercial kitchens.

The convenience factor cannot be overlooked. Commercial air fryers come with features like digital controls, programmable settings, and even self-cleaning functions. These innovations not only make the cooking process simpler but also save time for busy chefs and kitchen staff.

The demand for versatile appliances has surged as operators seek to offer a wider range of menu items. Modern commercial air fryers are designed to handle a variety of foods, from fried chicken and French fries to vegetables and even desserts. This flexibility has made them a staple in numerous food service operations.

In terms of consumer preferences, there’s a clear trend towards compact and portable air fryers. Operators in fast-casual restaurants and food trucks are gravitating towards these smaller models, which can be easily integrated into limited space and moved around as needed.

Sustainability is also a significant driver in the commercial air fryer sector. As businesses look to reduce waste and embrace eco-friendly practices, the use of air fryers that require less packaging and produce less waste has become a preferred option.

Customization is another area where the market is seeing growth. Many commercial air fryers now come with adjustable temperature controls and cooking times, allowing operators to tailor the cooking process to specific recipes and preferences.

Health and wellness have become central themes in the food industry, and air fryers are at the forefront of this movement. The ability to prepare crispy, delicious foods with less oil is not only appealing to health-conscious consumers but also aligns with the broader trend of clean eating.

Smart technology is also making its mark in the commercial air fryer sector. Some models now come with Bluetooth connectivity, allowing for remote control and monitoring of cooking processes. This integration of technology is expected to become more prevalent as operators seek to streamline their operations and enhance the customer experience.

As the market continues to evolve, there’s a growing interest in air fryers that can be integrated into larger kitchen systems. This could include features like batch cooking capabilities, multi-functional cooking zones, and even the ability to connect with other kitchen appliances for a seamless workflow.

Lastly, the trend towards global cuisine has influenced the commercial air fryer sector. Operators are looking for air fryers that can handle a variety of cooking techniques from different cultures, ensuring they can offer a diverse menu that caters to a broad range of tastes.

In conclusion, the commercial air fryer sector is a dynamic and rapidly growing market, driven by health, convenience, sustainability, and technological advancements. As these trends continue to shape consumer preferences, the future looks bright for this innovative cooking solution.

Commercial air fryers have emerged as a revolutionary technology in the kitchen appliance sector, and their impact on health and sustainability is profound. These innovative appliances have transformed the way we cook, offering numerous benefits that extend beyond just convenience.

The health benefits of commercial air fryers are substantial. Traditional frying methods, such as deep-frying, involve submerging food in oil, which can lead to a high intake of unhealthy fats and calories. In contrast, air frying uses hot air to circulate around the food, creating a crispy outer layer with minimal oil. This method significantly reduces the fat content of fried foods, making them a healthier alternative for those looking to maintain a balanced diet. For example, a study published in the Journal of Food Science found that air-fried French fries had up to 75% less fat than their deep-fried counterparts.

Moreover, the lower oil content means that the food retains more of its natural flavors and nutrients. This is particularly important for vegetables, which can lose up to 50% of their nutrients when cooked in excessive oil. By air frying, chefs and home cooks alike can enjoy a more nutritious and flavorful meal.

In terms of sustainability, commercial air fryers play a crucial role in reducing our environmental footprint. Traditional deep-frying requires large quantities of oil, which not only contributes to health issues but also to waste. When the oil becomes old or rancid, it must be discarded, adding to the burden on landfills. Air fryers, on the other hand, use a fraction of the oil, making them a more eco-friendly choice. This reduction in oil usage also translates to less demand for vegetable oils, which are often sourced from crops that compete with food crops for land and water resources.

Additionally, the energy efficiency of commercial air fryers cannot be overlooked. These appliances typically use around 70-80% less energy than deep fryers, which means they contribute less to greenhouse gas emissions. In a world increasingly focused on reducing carbon footprints, the energy-saving aspect of air fryers is a significant advantage.

The sustainability impact extends beyond the appliance itself. The use of air fryers encourages a shift towards healthier cooking practices, which can have a ripple effect on food waste. With less oil and a more controlled cooking process, there’s less likelihood of overcooking or burning food, reducing the amount of waste generated in commercial kitchens.

Furthermore, the versatility of commercial air fryers promotes the use of a wider variety of ingredients. Chefs and cooks can experiment with different types of food without the fear of excessive oil usage, leading to a more diverse and sustainable menu. This can include incorporating more whole grains, legumes, and seasonal produce, which are not only healthier but also more sustainable due to their lower environmental impact.

The rise of commercial air fryers has also sparked a conversation about the importance of food labeling and transparency. As consumers become more health-conscious and environmentally aware, they demand to know how their food is prepared. Air fryers provide a clear, healthy alternative, pushing manufacturers and foodservice providers to be more transparent about their cooking methods.

In the realm of health, commercial air fryers have become a beacon of hope for those with dietary restrictions. For instance, individuals with heart conditions or those following a low-fat diet can now enjoy fried foods without the guilt. This accessibility to healthier options can have a significant impact on public health, potentially reducing the incidence of chronic diseases associated with unhealthy cooking methods.

From a social standpoint, the popularity of air fryers has also influenced food culture. Chefs and home cooks are now more likely to share recipes and cooking techniques that are not only delicious but also mindful of health and sustainability. This shift has sparked a wave of innovation in the culinary world, with new recipes and cooking styles that are both satisfying and responsible.

In conclusion, the impact of commercial air fryers on health and sustainability is multifaceted. They offer a healthier alternative to traditional frying methods, reduce environmental strain by using less oil and energy, and promote a culture of responsible cooking. As the market for these appliances continues to grow, their influence on both personal health and global sustainability is poised to become even more significant.

The intricate production process at a commercial air fryer factory is a testament to the blend of advanced technology and meticulous craftsmanship. From the raw materials to the final product, every step is crucial in ensuring that the end result is a high-quality, efficient appliance.

Materials Sourcing and Quality ControlThe journey begins with the selection of high-grade materials. Aluminum, stainless steel, and plastic are commonly used, each chosen for its specific properties. The factory meticulously evaluates suppliers to guarantee the purity and durability of the components. Quality control teams inspect the incoming materials to prevent any substandard parts from entering the production line.

Design and PrototypingOnce the materials are verified, the design phase kicks off. Engineers use computer-aided design (CAD) software to create detailed blueprints of the air fryer. Prototypes are then crafted, allowing engineers to test the feasibility of the design and make necessary adjustments. This iterative process ensures that the final product is not only functional but also user-friendly.

Molding and AssemblyThe body of the air fryer is typically made from plastic, which is molded into shape using high-pressure machinery. These molds are precision-engineered to ensure the correct dimensions and structural integrity. After molding, the plastic parts are cleaned and dried to remove any excess material. The assembly line then brings these parts together, where they are joined with metal components such as the heating element and fan.

Electronics and Heating ElementsThe heart of a commercial air fryer lies in its electronics. The factory’s skilled technicians install circuit boards and wiring, which control the heating elements and fan. These components are carefully tested for electrical integrity and thermal resistance. The heating elements, often made of nichrome wire, are wrapped in ceramic fiber to ensure even heat distribution and longevity.

Cooking Chamber ConstructionThe cooking chamber is a critical part of the air fryer, where food is cooked. It is typically made from stainless steel for its durability and ability to withstand high temperatures. The chamber undergoes a series of checks to ensure it is free from imperfections and can withstand the pressure from the fan and air flow. Specialized welding techniques are used to join the parts without creating weak spots.

Painting and FinishingOnce the structural components are assembled and tested, they are ready for painting. A high-quality, heat-resistant paint is applied to protect the metal parts from corrosion and to enhance the aesthetics of the air fryer. The paint is cured in an oven to ensure it bonds properly and develops the necessary hardness. After curing, the parts are carefully inspected for any defects in the finish.

Safety and Compliance TestingBefore an air fryer leaves the factory, it must pass rigorous safety and compliance tests. These include checking for electrical safety, thermal limits, and structural integrity. Compliance with international safety standards, such as CE or UL, is paramount. Any units that fail these tests are either repaired or discarded to maintain the factory’s reputation for quality.

Packaging and Quality AssuranceOnce the air fryers pass all quality checks, they are packaged. Each unit is carefully wrapped, and protective materials like foam are used to prevent damage during shipping. Quality assurance teams conduct a final visual inspection to ensure that every product meets the factory’s high standards before it is shipped to customers.

The production process at a commercial air fryer factory is a blend of precision, craftsmanship, and cutting-edge technology. Each step is carefully managed to ensure that the final product is a reliable, efficient, and safe appliance that stands out in the competitive kitchen appliance market.

In the commercial air fryer manufacturing sector, maintaining the highest standards of quality and safety is paramount. This ensures that each product that leaves the factory not only meets but exceeds consumer expectations. Let’s delve into the intricate details of this process.

The meticulous inspection of raw materials is the foundation of quality control. Suppliers are carefully chosen based on their ability to provide high-quality components that are free from defects. Aluminum, stainless steel, and other metals used in the construction of commercial air fryers must be of the finest grade to ensure durability and longevity.

Before assembly begins, every part is individually tested for compliance with specifications. Advanced technology, such as automated optical inspection (AOI) systems, scans components for any surface imperfections that might compromise the integrity of the finished product. This ensures that only parts that meet precise dimensions and tolerances are used.

The assembly line is designed to minimize human error, with robots and precision machinery handling the intricate parts. Workers are trained to pay attention to the smallest details, such as ensuring that all screws are tight and that electrical connections are secure. Each unit is assembled in a clean, dust-free environment to prevent contamination.

Safety is woven into the very fabric of the production process. Factories adhere to strict safety protocols that include regular maintenance checks of machinery to prevent malfunctions. Workers are equipped with personal protective equipment (PPE), including safety glasses, gloves, and ear protection, to shield them from potential hazards.

During the manufacturing process, temperature control is crucial. The heat generated by the fryers must be monitored to ensure that it is consistent and safe for use. Overheating can lead to a risk of fire or burns, so thermal sensors and automatic shut-off systems are employed to maintain safe operating conditions.

The quality of the cooking oil is another critical factor. Commercial air fryers use high-quality, food-grade oils that are carefully monitored for purity and freshness. Regular testing ensures that the oil does not degrade over time, which can lead to health risks or poor performance of the fryer.

Once the air fryers are assembled, they undergo a series of rigorous tests to simulate real-world usage. These tests include checking for proper functioning of the heating elements, air flow, and safety features. The units are subjected to high temperatures and pressures to ensure they can withstand heavy use without failure.

Safety standards also extend to the electrical components. Each unit is tested for electrical conductivity and insulation resistance to prevent the risk of electrical shock. Compliance with international safety certifications, such as CE, UL, and RoHS, is verified at each stage of production.

In the packaging phase, quality control continues. Products are packaged in protective materials that prevent damage during shipping. Barcode scanning systems ensure that the correct products are packaged with the right labels, including safety warnings and usage instructions.

After packaging, the units are subjected to a final visual inspection and quality check. Only after passing this final review are they deemed ready for distribution. This final stage is often accompanied by a random sampling for more thorough quality assurance testing.

In conclusion, the production process at a commercial air fryer factory is a meticulous balance of precision engineering, adherence to safety standards, and unwavering commitment to quality. From the selection of raw materials to the final quality check, every step is designed to ensure that the end product is a safe, reliable, and high-performing air fryer that consumers can trust.

In the fast-paced world of commercial air fryer manufacturing, technology plays a pivotal role in driving efficiency and excellence. From automated assembly lines to advanced testing procedures, the integration of tech has transformed the way these appliances are produced. Here’s a closer look at how technology is reshaping the efficiency landscape within commercial air fryer factories.

Modern commercial air fryer factories are equipped with cutting-edge robotics that streamline the assembly process. These robots can handle tasks such as welding, soldering, and precision parts placement with unmatched accuracy. The result is a consistent and high-quality product, as human error is minimized, and the production speed is significantly increased.

Automation doesn’t stop at the assembly line. In the design phase, computer-aided design (CAD) software allows engineers to create detailed 3D models of air fryers, which can be tested and refined virtually before a single part is manufactured. This not only reduces the time and cost of prototyping but also ensures that the final product meets the highest standards of design and functionality.

Energy efficiency is a critical concern in any manufacturing setting, and commercial air fryer factories are no exception. Advanced energy management systems are used to monitor and control the factory’s energy consumption. These systems optimize power usage by adjusting the energy-intensive processes based on real-time data, leading to substantial energy savings and a reduced carbon footprint.

The quality control process is also enhanced by technology. High-resolution cameras and sensors are integrated into the production line to inspect parts and assembled units for defects. This ensures that only products that meet the stringent quality standards make it to the market. Any deviation from the set parameters triggers an immediate alert, allowing for quick corrective action.

In the realm of sustainability, technology is instrumental in recycling and waste reduction. Commercial air fryer factories are adopting advanced recycling processes to repurpose materials that would otherwise be discarded. For instance, the use of robotics to disassemble and sort electronic components allows for the recovery of valuable metals and plastics.

Safety is paramount in any manufacturing environment, and technology is at the forefront of ensuring a secure workplace. Smart sensors and automated systems can detect and prevent hazardous situations before they occur. For example, if a machine overheats or malfunctions, the system can shut it down automatically, preventing accidents and downtime.

The integration of the Internet of Things (IoT) has also revolutionized the management of commercial air fryer factories. IoT devices can collect and analyze vast amounts of data, providing insights into production patterns, equipment performance, and energy use. This data-driven approach allows for predictive maintenance, where potential issues are addressed before they lead to breakdowns.

In the realm of supply chain management, technology has improved logistics and inventory control. Real-time tracking systems ensure that parts and components are delivered on time, reducing production bottlenecks. Additionally, inventory management software helps to optimize stock levels, minimizing waste and ensuring that production can continue smoothly.

As the industry evolves, so does the technology within commercial air fryer factories. Research and development (R&D) departments are constantly exploring new innovations, such as AI-driven predictive analytics for product design and market trends. This continuous pursuit of technological advancement ensures that commercial air fryer factories remain at the cutting edge of efficiency and sustainability.

The use of augmented reality (AR) and virtual reality (VR) in training and development is another significant technological advancement. These tools provide a safe and interactive environment for employees to learn and practice their skills, reducing the time and cost associated with traditional training methods.

In conclusion, technology is the driving force behind the efficiency of commercial air fryer factories. From robotics and automation to energy management and safety systems, the integration of tech is transforming the way these appliances are produced. As technology continues to evolve, we can expect even greater improvements in the efficiency and sustainability of commercial air fryer manufacturing.

In the world of commercial air fryers, a few brands have stood out, not just for their products but for their innovative approaches and market success. Let’s delve into the stories of some of these successful commercial air fryer brands.

The brand AirFryerPro has gained a reputation for its cutting-edge technology and sleek designs. Their air fryers are not only a hit in commercial kitchens but also among health-conscious consumers who seek a healthier alternative to traditional frying methods. The brand’s commitment to quality and durability has made it a favorite among chefs and foodservice operators.

Another standout is Chef’s Choice Air Fryers, which has managed to blend advanced features with user-friendliness. Their products are known for their ability to produce crispy, delicious results with minimal oil, making them an attractive option for those looking to offer healthier menu items. The brand’s focus on energy efficiency and eco-friendly materials has also resonated with environmentally conscious consumers.

HealthyBake Air Fryers has carved a niche for itself by emphasizing health and wellness. Their air fryers are designed to reduce the amount of oil used in cooking, which appeals to health enthusiasts. The brand’s marketing strategy, which highlights the benefits of air frying over traditional frying methods, has helped to position them as a leader in the market.

FastCook Air Fryer Systems has made waves with its compact and versatile air fryers, which are perfect for busy kitchens. Their products are known for their quick cooking times and ability to handle a variety of recipes, from fried chicken to vegetables. The brand’s focus on ease of use and convenience has made them a go-to choice for many commercial kitchens.

EcoFry Air Fryers has differentiated itself by focusing on sustainability. Their air fryers are built with eco-friendly materials and are designed to be energy-efficient, reducing the carbon footprint of commercial kitchens. The brand’s commitment to sustainability has not only helped them attract environmentally conscious customers but has also given them a unique selling point in a crowded market.

CulinaryAir Air Fryers has gained a loyal following by offering a range of air fryers that cater to different cooking needs. From countertop models to larger commercial units, the brand’s diverse product line ensures that there’s an air fryer for every kitchen. Their focus on innovation, such as incorporating smart technology for precise temperature control, has set them apart from competitors.

SmartAirFryer Solutions has taken the commercial air fryer market by storm with their integration of smart technology. Their air fryers can be controlled remotely through apps, allowing chefs to monitor and adjust cooking times and temperatures from anywhere. This level of convenience and control has made them a favorite among busy chefs and operators.

PowerFry Air Fryers has distinguished itself by focusing on high-performance units designed for high-volume cooking. Their commercial air fryers are built to withstand heavy use, making them ideal for restaurants and foodservice operations. The brand’s focus on power and efficiency has helped them establish a strong presence in the commercial kitchen equipment market.

AirCrisp Air Fryers has gained a reputation for their ability to replicate the taste and texture of fried food without the guilt. Their air fryers are known for their even cooking and ability to produce crispy, golden-brown results. The brand’s commitment to delivering a high-quality product at a competitive price has helped them build a strong customer base.

These case studies of successful commercial air fryer brands illustrate the importance of innovation, quality, and market differentiation. From focusing on health and sustainability to integrating smart technology and offering versatile products, these brands have found their way to the top by understanding the needs of their customers and delivering solutions that meet those needs effectively.

In the ever-evolving landscape of commercial air fryer factories, the future holds a plethora of possibilities. From advancements in technology to emerging market trends, the next wave of innovation promises to reshape the industry. Let’s delve into what could be in store for these factories.

As consumer preferences shift towards healthier eating habits, the demand for commercial air fryers is expected to soar. These appliances are not just a trend; they are a testament to the changing times, where convenience meets health. The future of commercial air fryer factories lies in their ability to adapt to these shifting demands, offering products that cater to both the taste and the health consciousness of consumers.

One significant development is the integration of smart technology. Imagine a commercial air fryer that not only cooks food efficiently but also learns from user preferences and adjusts its settings accordingly. This level of personalization is not far-fetched; in fact, some factories are already working on such cutting-edge technology. The future could see a surge in smart appliances that not only save time but also provide a tailored cooking experience.

Energy efficiency is another area where commercial air fryer factories are likely to focus. With environmental concerns on the rise, the next generation of air fryers might come with features that reduce energy consumption without compromising on performance. This could involve the use of advanced insulation materials, more efficient heating elements, and intelligent systems that adjust cooking times based on the type of food being prepared.

The rise of modular designs in commercial air fryer factories is also a trend worth watching. By creating appliances that can be customized or upgraded, factories can cater to a wider range of customer needs. For instance, a commercial kitchen might require a larger capacity air fryer, while a food truck could benefit from a portable, compact model. Modular designs allow for flexibility and scalability, ensuring that factories can keep pace with the diverse demands of the market.

Sustainability is a key driver in the future of commercial air fryer manufacturing. As awareness grows about the environmental impact of food production, factories will be under pressure to adopt greener practices. This could mean sourcing materials from sustainable sources, reducing waste during production, and designing products that are recyclable or have a longer lifespan. The future factory will not only focus on the product itself but also on the entire lifecycle of the air fryer.

Collaborations between commercial air fryer factories and foodservice industry leaders are also on the horizon. By working closely with chefs and kitchen managers, factories can develop appliances that not only meet their technical requirements but also enhance the overall culinary experience. This partnership could lead to the creation of air fryers that not only cook food but also contribute to the aesthetic and functional design of a kitchen.

Globalization plays a crucial role in shaping the future of commercial air fryer factories. As these appliances become more popular worldwide, factories will need to consider international standards and regulations. This means not only adapting to different power sources and voltage requirements but also ensuring that their products meet the safety and quality expectations of diverse markets.

Innovation in material science is another area that could revolutionize the commercial air fryer industry. New materials could lead to lighter, more durable appliances that are easier to clean and maintain. For example, advancements in non-stick coatings could make air fryers even more convenient to use, reducing the need for oil and simplifying the cleaning process.

The future of commercial air fryer factories also hinges on the adoption of artificial intelligence and machine learning. These technologies could optimize production processes, predict maintenance needs, and even anticipate market trends. By harnessing the power of data, factories can streamline their operations and respond more effectively to consumer demands.

In conclusion, the future of commercial air fryer factories is bright and filled with potential. From technological advancements to sustainable practices, the industry is poised for significant growth. As factories continue to innovate and adapt, they will not only meet the needs of today’s consumers but also pave the way for a healthier, more efficient, and environmentally conscious future.