Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In a world where technology and convenience converge, the kitchen has become a canvas for innovation. As we delve into the realm of kitchen appliances, one particular category stands out for its transformative impact: air fryers. These appliances, once a niche product, have now become a staple in modern kitchens. Today, we explore the dynamic world of air fryer manufacturing, where Original Design Manufacturers (ODMs) play a pivotal role in shaping the future of kitchen appliances. From cutting-edge designs to market-driven solutions, the journey from an idea to a 30-day air fryer is a testament to the ingenuity and dedication of these ODMs.

The air fryer has quietly revolutionized the kitchen appliance landscape, becoming a staple in homes across the globe. Once a niche product, it has now emerged as a game-changer, offering a healthier alternative to traditional frying methods. With its ability to cook crispy, delicious food with minimal oil, the air fryer has captured the hearts and taste buds of health-conscious consumers and culinary enthusiasts alike.

Gone are the days when deep-frying was the only way to achieve that perfect golden-brown crust. The air fryer uses rapid air circulation to mimic the frying process, resulting in a similar texture without the excessive oil. This innovation has not only changed how we cook but also how we perceive healthy eating. The convenience and efficiency of air fryers have made them a must-have for any modern kitchen.

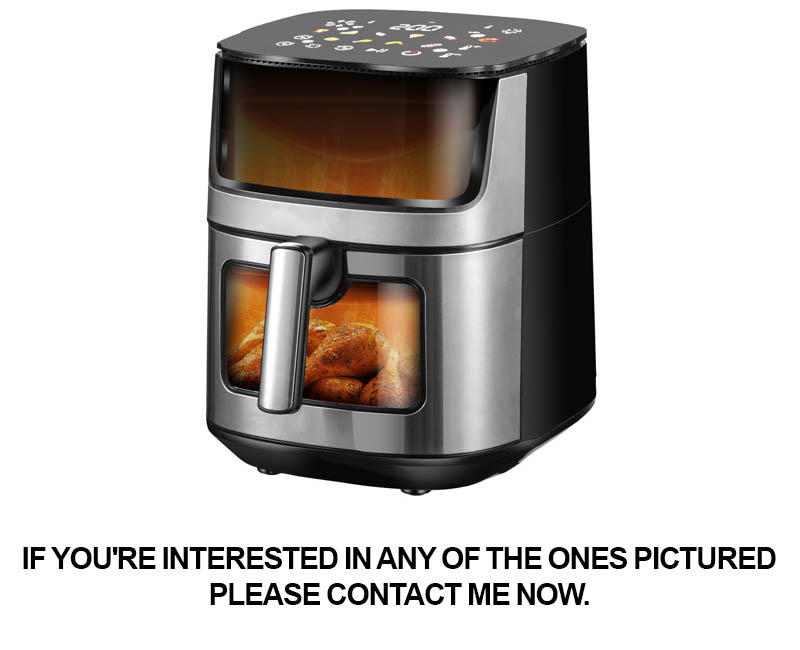

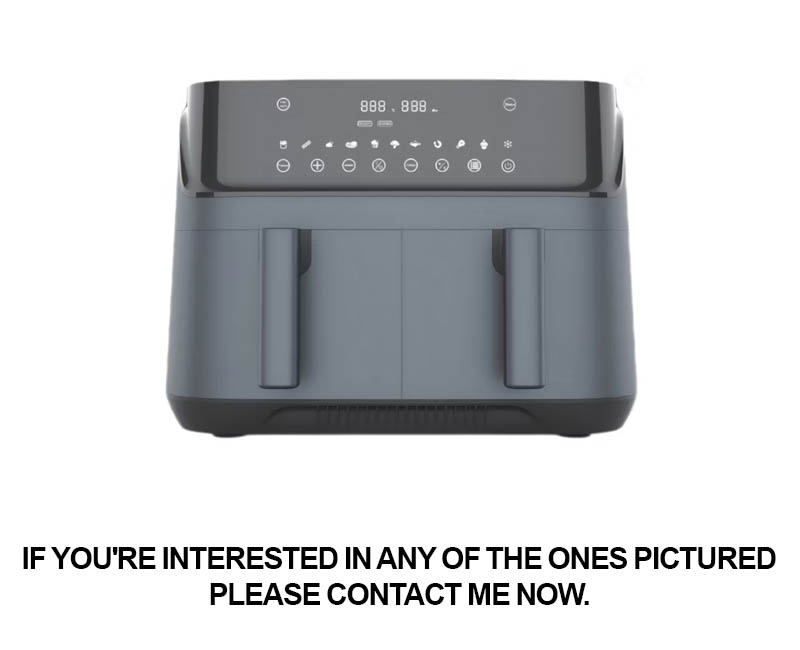

As the demand for air fryers continues to soar, manufacturers are pushing the boundaries of innovation. From compact countertop models to multifunctional kitchen gadgets, the variety of air fryers available today is impressive. But what drives this surge in popularity? Let’s delve into the factors that have propelled the air fryer into the spotlight.

Firstly, health and wellness have become top priorities for many consumers. With the rise of obesity and related health issues, people are seeking out healthier cooking methods. Air frying offers a way to enjoy fried foods without the guilt, as it uses up to 80% less oil than traditional frying. This has made it a favorite among those looking to maintain a balanced diet while still indulging in their favorite treats.

Secondly, the convenience of air fryers cannot be overlooked. These appliances are designed to be easy to use and clean, making them perfect for busy lifestyles. With simple settings and minimal prep time, air fryers have become a go-to option for quick and effortless meals. Whether you’re cooking for one or hosting a crowd, an air fryer can handle it all with ease.

Moreover, the versatility of air fryers has expanded their appeal. They can cook a wide range of foods, from vegetables and meats to bread and desserts. This versatility has allowed manufacturers to create unique and innovative models that cater to specific dietary preferences and restrictions. For example, some air fryers are designed to be gluten-free or to cook foods at specific temperatures for sous-vide cooking techniques.

The environmental impact of cooking methods has also played a role in the air fryer’s rise. Traditional frying methods contribute to high levels of oil waste and can be harmful to the environment. Air fryers, on the other hand, are more sustainable and eco-friendly. By reducing oil usage and energy consumption, air fryers are a greener choice for those concerned about their carbon footprint.

The technology behind air fryers has also advanced significantly. Modern models come with features like adjustable temperature controls, timers, and even preset cooking programs for different types of food. These advancements have made air fryers more reliable and user-friendly, further contributing to their popularity.

In addition to consumer demand, the food industry has recognized the potential of air fryers. Many restaurants and foodservice establishments have started incorporating air fryers into their kitchens to offer healthier options to their customers. This has helped to normalize air frying as a cooking method and has further fueled its growth.

The rise of the air fryer has also created opportunities for manufacturers and entrepreneurs. The market for air fryers is expanding rapidly, and there is a constant need for new and improved models. This has led to a surge in innovation, with companies investing in research and development to create the next big thing in kitchen appliances.

In conclusion, the air fryer’s rise to prominence in the kitchen appliance market is a testament to the power of innovation and consumer demand. As people continue to seek healthier, more convenient, and sustainable cooking methods, the air fryer is poised to remain a staple in modern kitchens. Its ability to deliver delicious results with minimal oil and maximum convenience has made it a game-changer that is here to stay.

ODM, or Original Design Manufacturing, has emerged as a cornerstone in the kitchen appliances industry, particularly in the realm of air fryers. This concept is not just about producing goods; it’s about crafting solutions that resonate with the unique needs and preferences of consumers. Let’s delve into what ODM entails and why it’s pivotal in the air fryer market.

The essence of ODM lies in the fusion of creativity and practicality. It’s about taking a client’s vision and transforming it into a tangible product that not only meets but exceeds expectations. In the case of air fryers, this often means designing appliances that are not only efficient and safe but also aesthetically pleasing and user-friendly.

In the competitive landscape of air fryers, ODM stands out as a strategy that allows companies to differentiate themselves. By offering custom solutions, manufacturers can cater to niche markets, such as those seeking eco-friendly models or compact appliances for small kitchens. This level of customization is something that mass-produced products often struggle to achieve.

One of the key advantages of ODM is the flexibility it provides. Designers and engineers can work closely with clients to iterate and refine the product, ensuring that every detail is meticulously considered. This collaborative approach is particularly valuable in the fast-evolving air fryer market, where new technologies and consumer trends are constantly reshaping the industry.

The process of ODM is a complex one, involving several stages. It begins with market research to understand the latest consumer demands and technological advancements. This is followed by concept development, where ideas are sketched out and prototyped. The prototypes are then tested for functionality, safety, and usability, with adjustments made based on feedback.

One of the standout features of ODM is the emphasis on innovation. Designers are encouraged to push boundaries and explore new materials, features, and functionalities. This can lead to the creation of air fryers that not only cook food more healthily but also offer additional benefits, such as programmable settings or smart connectivity.

The quality control aspect of ODM is also crucial. Since each product is a custom design, the standards for quality are set at the highest level. This means rigorous testing to ensure that every air fryer meets the stringent safety and performance criteria. The result is a product that not only looks great but also performs reliably.

Another important aspect of ODM is the intellectual property protection it offers. By working with an ODM partner, companies can secure their designs and innovations, preventing competitors from copying their products. This is particularly relevant in the air fryer market, where imitation can be a significant threat.

Cost-effectiveness is often a concern when considering ODM. However, when done right, ODM can actually be more cost-efficient in the long run. By streamlining the design and production process, ODM partners can help reduce time-to-market and minimize the risk of costly redesigns. This, in turn, allows companies to bring high-quality, innovative products to market faster and at a competitive price.

Collaboration is at the heart of ODM. It requires a strong partnership between the client and the ODM provider, built on trust and a shared vision. This relationship is dynamic, with both parties contributing their expertise and insights. The end result is a product that is not just a reflection of the client’s brand but also a testament to the synergy between the two entities.

In the context of air fryers, ODM has become a vital tool for companies looking to establish a strong presence in the market. It allows them to offer unique, cutting-edge products that stand out from the crowd. Whether it’s through innovative features, eco-friendly materials, or smart technology, ODM enables companies to deliver products that truly resonate with consumers.

In conclusion, ODM is not just a service; it’s a strategic approach to product development that can make a significant impact on the success of a company in the air fryer industry. By combining creativity, quality, and collaboration, ODM helps to shape the future of kitchen appliances, one custom solution at a time.

Choosing a 30-Day Air Fryer Original Design Manufacturer (ODM) from China offers a myriad of advantages that can significantly impact your business and product quality. Here’s why it’s a compelling choice:

The Cost-Effective AdvantageManufacturing in China is renowned for its cost efficiency. The lower labor costs, coupled with economies of scale, mean that you can get high-quality air fryers at a fraction of the price compared to other regions. This cost-effectiveness allows businesses to invest more in marketing, innovation, or even offer competitive pricing to consumers.

Expertise in Electronics and AppliancesChina has a long-standing reputation in electronics and appliance manufacturing. With decades of experience, Chinese factories have honed their skills in producing reliable and durable kitchen appliances. When you opt for a 30-Day Air Fryer ODM from China, you’re tapping into a pool of expertise that ensures your product meets the highest standards of quality and performance.

Rapid Prototyping and ProductionChinese ODMs are adept at rapid prototyping, which is crucial for bringing new products to market quickly. The streamlined production processes and the ability to produce in large volumes mean that you can get your 30-Day Air Fryer to market faster, staying ahead of the competition and capitalizing on market trends.

Customization and InnovationOne of the standout benefits of working with a Chinese ODM is the level of customization and innovation they offer. They can take your initial concept and turn it into a reality, often with unique features and design elements that set your product apart. This level of personalization can be a game-changer in a crowded market, making your air fryer stand out to consumers.

Quality Control and AssuranceDespite the lower costs, Chinese ODMs are known for their rigorous quality control processes. They adhere to international standards and often have certifications that guarantee the quality of their products. This means that when you choose a 30-Day Air Fryer ODM from China, you can be confident that the final product will meet or exceed your expectations.

Sustainability and Environmental ResponsibilityChinese manufacturers are increasingly focusing on sustainability and environmental responsibility. They are investing in green technologies and practices to reduce waste and emissions. By choosing a Chinese ODM for your 30-Day Air Fryer, you’re not only getting a cost-effective solution but also contributing to a more sustainable future.

Global Supply Chain and DistributionChina’s strategic location and well-developed infrastructure make it a hub for global trade. When you work with a Chinese ODM, you gain access to a robust supply chain that can handle everything from raw materials to shipping and logistics. This ensures that your 30-Day Air Fryers can be distributed efficiently and effectively worldwide.

Market Access and UnderstandingChinese ODMs have a deep understanding of both the domestic and international markets. They can provide valuable insights into consumer preferences, regulatory requirements, and market trends. This knowledge can be invaluable in tailoring your air fryer to specific markets and ensuring compliance with local standards.

Financial FlexibilityMany Chinese ODMs offer flexible payment terms and financing options, which can be particularly beneficial for small and medium-sized enterprises (SMEs) or startups. This financial flexibility can help you manage cash flow and mitigate risks associated with new product development.

Long-Term PartnershipsChoosing a 30-Day Air Fryer ODM from China can lead to long-term partnerships. Chinese manufacturers are often willing to invest in long-term relationships, which can result in continuous improvement and innovation. This can be a significant advantage as your business grows and evolves.

In summary, selecting a 30-Day Air Fryer ODM from China offers a combination of cost savings, expertise, customization, quality control, sustainability, and market access. These factors make it an attractive choice for businesses looking to enter or expand in the air fryer market with a product that stands out for its quality and innovation.

Partnering with Chinese Original Design Manufacturers (ODMs) for air fryers offers a multitude of advantages that can significantly elevate your product’s quality, market appeal, and overall success. Here’s a closer look at some of the key benefits:

Cost-Effective ProductionManufacturing costs in China are often lower compared to other regions, which can lead to substantial savings for your business. The economies of scale and efficient supply chains in China mean that you can get high-quality components and finished products at competitive prices, allowing for better profit margins.

Access to Skilled LaborChinese ODMs have access to a vast pool of skilled labor, including engineers, designers, and technicians. This expertise ensures that your air fryer is not only designed to meet the latest industry standards but is also crafted with precision and care.

State-of-the-Art TechnologyChina is a global leader in technology and manufacturing. By collaborating with a Chinese ODM, you gain access to cutting-edge technology and innovative solutions that can give your air fryer a competitive edge in the market.

Customization and FlexibilityChinese ODMs are known for their ability to customize products to meet specific requirements. Whether you need a unique feature, a particular size, or a specialized design, Chinese ODMs can accommodate your needs, allowing you to create a product that stands out in the market.

Quality ControlQuality is a top priority in Chinese manufacturing. ODMs in China adhere to strict quality control measures, ensuring that each air fryer meets the highest standards. This includes rigorous testing and certifications, giving you peace of mind that your product will perform reliably.

Speed to MarketThe streamlined processes and efficient production lines in China can significantly reduce the time it takes to bring a product to market. This agility is crucial in a fast-paced industry where being first to market can mean capturing a larger share of the consumer base.

Diverse Range of MaterialsChinese ODMs have access to a wide range of materials, from durable plastics to high-quality metals, which can be used to create air fryers that are both functional and visually appealing. This diversity allows for creative design and customization without compromising on quality.

SustainabilityMany Chinese ODMs are committed to sustainable practices, which can be a significant selling point for eco-conscious consumers. By choosing a Chinese ODM, you can ensure that your air fryer is produced in an environmentally responsible manner.

Extensive Market KnowledgeChinese ODMs are well-versed in the local and international markets, including the latest trends and consumer preferences. This knowledge can be invaluable in designing air fryers that resonate with target audiences and meet their expectations.

Innovation and R&DChina is a hub for research and development, and many ODMs invest heavily in innovation. This means that you can tap into a wealth of new ideas and technologies that can enhance your air fryer’s features and performance.

Global Supply ChainChinese ODMs have established relationships with suppliers all over the world, which can simplify the procurement process and ensure a steady supply of high-quality components. This global network can also help in managing risks associated with supply chain disruptions.

Continuous ImprovementThe competitive nature of the Chinese market drives ODMs to continuously improve their products and services. This means that by working with a Chinese ODM, you’re likely to benefit from ongoing enhancements and updates to your air fryer design.

Brand DevelopmentPartnering with a reputable Chinese ODM can also help in building your brand. With their expertise in manufacturing and market understanding, they can assist in creating a strong brand identity and ensuring that your product is well-received by consumers.

Financial IncentivesIn addition to the cost savings, some Chinese ODMs may offer financial incentives such as discounts or payment terms that can further benefit your business.

In summary, choosing a 30-Day Air Fryer ODM from China offers a blend of cost-effectiveness, quality, innovation, and market knowledge that can make a significant impact on your product’s success.

In the ever-evolving world of kitchen appliances, air fryers have emerged as a game-changer, offering a healthier alternative to deep-frying. The key to standing out in this competitive market lies in innovative designs that not only appeal to consumers but also enhance the functionality and user experience. Here’s how creativity is unleashed in the manufacturing of air fryers:

The Art of SimplicityDesigning an air fryer isn’t just about creating a gadget; it’s about crafting an experience. Manufacturers are focusing on simplicity, ensuring that the air fryer is intuitive and easy to use. From sleek, minimalist designs to clear, user-friendly interfaces, the emphasis is on making the appliance as accessible as possible without compromising on style.

Integrating Modern TechnologyIncorporating modern technology into air fryer designs is a must. Smart features like touchscreens, Bluetooth connectivity, and remote control capabilities are becoming standard. These advancements not only make the cooking process more convenient but also allow for customization and monitoring from anywhere in the home.

Functionality Meets AestheticsThe best air fryers are those that seamlessly blend functionality with aesthetics. Designers are pushing the boundaries by creating units that not only perform well but also look great on the countertop. This includes using high-quality materials, incorporating unique shapes, and offering a range of colors to suit different kitchen decors.

Safety and AccessibilitySafety is paramount in kitchen appliance design. Manufacturers are focusing on creating air fryers with safety features such as automatic shut-off, cool-touch handles, and child locks. Additionally, accessibility is being addressed through larger buttons, adjustable racks, and ergonomic designs that cater to users of all ages and abilities.

Unique Cooking FeaturesInnovation in air fryer manufacturing extends beyond the basics. Companies are introducing unique cooking features like adjustable temperature controls, multiple cooking modes, and even built-in timers. These features allow users to experiment with different recipes and cooking techniques, making the air fryer a versatile kitchen tool.

Smart and Sustainable DesignThe trend towards sustainability is influencing air fryer design as well. Manufacturers are exploring eco-friendly materials and energy-efficient technologies to reduce the environmental impact of their products. This includes designing for longevity, making parts replaceable, and considering the entire lifecycle of the air fryer.

Customization for Different MarketsDesigners are also taking into account the specific needs of different markets. For example, certain regions may prefer larger capacity air fryers or those with specific cooking modes tailored to local cuisine. This customization ensures that the air fryer is not only innovative but also culturally relevant.

Interactive and Educational DesignsTo engage consumers and educate them about the benefits of air frying, manufacturers are incorporating interactive elements into their designs. This can include digital recipe books, cooking tutorials, and even social media integration to share recipes and cooking tips.

Collaboration with Chefs and FoodiesCollaborating with chefs and food enthusiasts is another way that creativity is unleashed in air fryer manufacturing. These partnerships help to identify emerging trends and cooking techniques that can be integrated into new product designs, ensuring that the air fryer remains at the forefront of culinary innovation.

In conclusion, the manufacturing of air fryers is a blend of art and science, where designers and engineers work together to create products that are not only functional but also inspiring. By focusing on simplicity, technology, safety, and sustainability, air fryer manufacturers are setting the stage for a new era of kitchen appliances that are as innovative as they are indispensable.

In the fast-paced world of kitchen appliances, the quality of an air fryer can make or break a brand’s reputation. Ensuring top-notch performance and reliability is paramount, which is why rigorous quality control is non-negotiable. Let’s delve into the nuances of maintaining excellence in air fryer manufacturing.

The foundation of quality control lies in meticulous sourcing. Choosing the right raw materials is crucial; the quality of the plastic, metal, and other components directly impacts the durability and efficiency of the air fryer. Suppliers must undergo strict evaluations to ensure they meet the stringent standards set by reputable ODMs (Original Design Manufacturers) like us.

Once the materials are selected, the manufacturing process must be meticulously monitored. Every step, from cutting and shaping to assembling and testing, is critical. Skilled technicians oversee the production line, ensuring that each air fryer is crafted to perfection. This attention to detail is what sets our products apart from the competition.

Durability tests are a cornerstone of our quality control process. Air fryers are subjected to a variety of stress tests to simulate real-world usage. These include dropping tests, vibration tests, and temperature extremes to ensure the appliance can withstand the rigors of everyday cooking. The results are often surprising, with many air fryers far exceeding industry standards.

Energy efficiency is another key aspect of quality control. We employ cutting-edge technology to ensure our air fryers use less electricity while cooking, which not only benefits the consumer but also supports environmental sustainability. Energy consumption is measured and optimized at every stage of the production cycle.

Safety is paramount in air fryer manufacturing. Regular inspections are conducted to ensure all electrical components are secure and insulated properly. We also conduct safety tests to ensure that the appliances do not overheat, pose a fire risk, or leak any harmful substances. This includes testing for leaks in the fry basket and ensuring the fan and heating element work harmoniously.

Functionality is tested to ensure that each air fryer performs as advertised. This involves cooking tests with various types of food to verify the air fryer’s ability to achieve a crispy outer layer and a tender interior. We also check the consistency of cooking across different batches to guarantee that each product delivers the same high-quality performance.

User experience is at the heart of our quality control strategy. We gather feedback from our customers to understand how they use their air fryers and identify any areas for improvement. This customer-centric approach helps us refine our products to better meet the needs and expectations of consumers.

In addition to internal testing, we also engage in third-party certifications. These certifications, such as those from the Underwriters Laboratories (UL) and the European Committee for Electrotechnical Standardization (CENELEC), validate the safety and quality of our air fryers. They are an essential part of our commitment to providing customers with products they can trust.

Regular updates and improvements are a constant in our quality control process. The technology and consumer demands evolve, and we stay ahead by continually updating our manufacturing processes and product designs. This includes incorporating new materials and technologies that can enhance the air fryer’s performance and user experience.

Finally, our quality control process extends beyond the factory. We work closely with our logistics partners to ensure that the air fryers arrive at the customer’s doorstep in perfect condition. This includes protective packaging and temperature-controlled shipping, especially for the air fryers that are sensitive to temperature changes.

In summary, quality control is not just a step in the manufacturing process; it’s a philosophy that drives us to deliver top-notch air fryers to our customers. From the initial design to the final delivery, every aspect is scrutinized and optimized to ensure that each air fryer we produce is a testament to our commitment to excellence.

The air fryer market is a rapidly evolving landscape, and staying ahead requires a keen eye on current trends and data insights. Here’s a deeper dive into what’s shaping the industry:

In recent years, we’ve seen a surge in health-conscious consumers, and this shift has significantly impacted the air fryer market. People are gravitating towards appliances that allow them to enjoy fried foods with a fraction of the fat, thanks to the technology that mimics deep-frying with little to no oil.

This consumer behavior is not just a fleeting trend; it’s a testament to the ongoing demand for healthier cooking methods. The data reflects a growing preference for air fryers, with sales figures climbing steadily each year. Market research shows that consumers are willing to invest in these kitchen gadgets for the long-term health benefits they offer.

Another key trend is the integration of smart technology. Smart air fryers that can be controlled remotely via an app are becoming increasingly popular. This connectivity not only adds convenience but also enhances the user experience. The data backs this up, indicating a strong correlation between the inclusion of smart features and customer satisfaction.

The design landscape is also shifting. Air fryers are no longer just utilitarian appliances; they are becoming fashion statements. Manufacturers are pushing the boundaries with sleeker designs, brighter colors, and innovative shapes. This is not just about aesthetics; it’s about meeting the diverse needs and preferences of consumers. Data indicates that the market for aesthetically pleasing kitchen appliances is expanding, and air fryers are not an exception.

The rise of subscription-based models is another interesting trend. Companies are offering air fryers and accompanying recipe boxes, providing customers with a monthly subscription that includes both the appliance and new, healthy recipes. This model not only locks in customers but also creates a continuous stream of data about usage patterns and consumer preferences.

The data insights we gather from customer feedback and market research are invaluable. They help us understand what features are most sought after, what kind of after-sales support is necessary, and how to anticipate future demands. For example, data has shown that many users appreciate a timer function for convenience, while others value the ability to monitor the cooking process remotely.

The global landscape is also influencing market trends. The air fryer market is experiencing growth across various regions, but certain countries are leading the charge. In Europe, for instance, the trend towards healthier cooking methods is particularly pronounced. Meanwhile, in Asia, the market is expanding rapidly as consumers become more health-conscious and affluent.

Innovation is not limited to design and technology; it also extends to the supply chain. The data reveals that suppliers who can offer competitive pricing without compromising on quality are gaining a competitive edge. This has led to a greater focus on sourcing high-quality materials and components that can be produced efficiently.

Finally, the importance of sustainability cannot be overstated. Consumers are increasingly looking for appliances that are eco-friendly, and the data confirms this trend. Air fryer manufacturers that prioritize sustainability in their production processes are likely to appeal to a wider customer base.

In conclusion, staying ahead in the air fryer industry is about staying informed and adaptable. By keeping a pulse on market trends and leveraging data insights, companies can anticipate changes, make informed decisions, and continue to deliver top-notch products that meet the evolving demands of health-conscious consumers around the world.

In today’s fast-paced world, consumer demands are ever-evolving, and the air fryer market is no exception. A customer-centric approach is essential for brands looking to stand out in a crowded marketplace. Here’s how tailoring air fryers to market needs can make all the difference:

Consumer Preferences are DiverseUnderstanding the varied preferences of consumers is crucial. From urban professionals seeking quick, healthy cooking options to health-conscious families looking for low-fat alternatives, air fryer manufacturers must cater to these diverse needs. By analyzing market trends and consumer feedback, brands can design products that resonate with different demographics.

Customization for Local MarketsGlobalization has brought the world closer, but local market nuances still play a significant role. In regions where traditional cooking methods are deeply rooted, air fryer designs should incorporate elements that are culturally acceptable and appealing. Chinese Original Design Manufacturers (ODMs) can provide solutions that are not just functional but also culturally sensitive.

Focus on Health and WellnessThe health and wellness trend is gaining momentum worldwide. Air fryers are seen as a healthier alternative to deep-frying due to their ability to reduce oil usage. Brands can capitalize on this by emphasizing the health benefits of their products. ODMs can assist in developing air fryers with features like temperature control and smart cooking modes that cater to health-conscious consumers.

Ease of Use and ConvenienceIn a time-starved society, convenience is king. Air fryers that are easy to use, clean, and maintain will always find a place in the market. ODMs can offer innovative solutions such as one-touch controls, intuitive interfaces, and removable baskets for effortless cooking and cleaning experiences.

Aesthetic Appeal and BrandingThe look and feel of an air fryer can be a deciding factor for many consumers. Aesthetically pleasing designs, combined with strong branding, can create a lasting impression. ODMs can help in creating air fryers that not only perform well but also look stylish and appealing, making them a desirable addition to any kitchen.

Incorporating TechnologyThe integration of technology is another key aspect. Smart air fryers that can be controlled via apps, offering recipes, and providing nutritional information are becoming increasingly popular. ODMs can develop air fryers with the latest tech features that enhance user experience and add value to the product.

Customized FunctionalityDifferent regions may have specific needs. For example, some markets might require air fryers with additional functionalities like rotisserie capabilities or dehydrator modes. ODMs can provide customized designs that meet these unique requirements, ensuring that the product is a perfect fit for the market.

SustainabilityConsumers are increasingly concerned about the environmental impact of their purchases. ODMs can help design air fryers that are not only energy-efficient but also made from sustainable materials. This focus on sustainability can be a powerful selling point for eco-conscious consumers.

Collaborative InnovationWorking closely with ODMs, brands can foster a culture of collaborative innovation. By sharing insights and feedback, brands can drive the development of new features and functionalities that address market needs. This collaborative approach can lead to the creation of cutting-edge air fryers that are both functional and user-friendly.

Customer Support and ServiceEven the best air fryer can face issues. Brands that invest in excellent customer support and service can differentiate themselves from competitors. ODMs can advise on how to design air fryers that are easy to service and come with robust warranties, enhancing the overall customer experience.

In conclusion, a customer-centric approach is pivotal in tailoring air fryers to market needs. By focusing on consumer preferences, incorporating technology, and ensuring quality and sustainability, brands can create air fryers that not only meet but exceed customer expectations. Partnering with ODMs that understand these dynamics is key to staying ahead in an ever-changing industry.

In the world of kitchen appliances, innovation is not just a buzzword; it’s a driving force behind the creation of products that revolutionize how we cook. When it comes to air fryers, the journey from an idea to a market-ready product is a testament to the meticulous process and dedication involved. Here’s a glimpse into how we transform concepts into 30-Day Air Fryers that not only stand out but also meet the expectations of modern consumers.

We start with a thorough understanding of market needs. This involves analyzing consumer trends, identifying gaps in existing products, and envisioning what the future kitchen will look like. It’s here that the concept for our 30-Day Air Fryer begins to take shape, driven by a desire to offer something that’s both innovative and practical.

Next comes the brainstorming session, where our team of designers, engineers, and product managers come together to hash out ideas. Each member brings their unique perspective and expertise, leading to a diverse range of concepts. This collaborative environment fosters creativity and ensures that no idea is left unexplored.

Once we have a list of potential designs, we begin the initial sketching phase. These sketches are the first visual representations of our ideas, allowing us to see how the product could look and function. This is where we start to refine our concept, focusing on aspects such as ease of use, compactness, and aesthetic appeal.

After the initial sketches, we move into the prototyping stage. Prototypes are the tangible versions of our designs, and they serve as a testing ground for both form and function. We use 3D modeling software to create a virtual prototype that can be easily modified, and we also work with manufacturing partners to create physical prototypes that we can hold and interact with.

Testing these prototypes is a critical step. We subject them to a variety of conditions to ensure they can withstand everyday use. This includes drop tests, heat and cold exposure, and stress tests to simulate the rigors of cooking. The feedback from these tests helps us identify any potential issues that need to be addressed before moving forward.

As we iterate on the design, we also consider the materials we’ll use. Durability, safety, and environmental impact are key factors in our decision-making process. We source materials from reliable suppliers who can guarantee the quality and sustainability of the components.

Once we have a design that passes all our rigorous tests, we begin the manufacturing process. This involves setting up production lines, training workers, and ensuring that every aspect of the manufacturing process is standardized to maintain quality. We also implement a system of continuous improvement, where we constantly seek ways to enhance the product and its production methods.

During the manufacturing phase, we place a strong emphasis on quality control. Each unit is inspected multiple times to ensure it meets our high standards. This includes checking for any defects, verifying that all components are correctly installed, and ensuring that the product operates as intended.

Once the air fryers are manufactured, we move on to packaging. The packaging not only protects the product during shipping but also serves as a marketing tool. We design packaging that is not only visually appealing but also functional, providing customers with a seamless unboxing experience.

Finally, we prepare for market launch. This involves coordinating with distribution channels, setting up marketing campaigns, and training sales teams. We also gather customer feedback before the product hits the shelves to make any final adjustments that may be necessary.

Throughout this entire process, we remain customer-centric. We listen to what consumers want and need, and we incorporate that feedback into every stage of development. Our goal is to create air fryers that not only meet expectations but exceed them, making cooking more enjoyable and healthier for everyone.

The journey from an idea to a 30-Day Air Fryer is a complex one, requiring a combination of creativity, technical expertise, and a relentless pursuit of perfection. It’s a testament to the dedication of our team and our commitment to bringing innovative, high-quality products to the market.

In the world of kitchen appliances, the success of a product often hinges on its ability to meet the unique needs and preferences of consumers. Our custom ODM (Original Design Manufacturer) services for air fryers have led to several success stories that highlight the importance of innovation, market understanding, and a customer-centric approach. Here are a few case studies that showcase the journey from concept to a 30-day air fryer that delighted our clients and customers alike.

One of our clients approached us with a specific challenge: they wanted to create an air fryer that was not only efficient and easy to use but also stylish and compact, ideal for small kitchens and urban dwellers. The initial concept was a sleek, modern design with a focus on energy efficiency and durability.

To bring this vision to life, our team of designers and engineers worked closely with the client. We started by conducting extensive market research to understand the latest trends and consumer preferences. This research led us to identify key features that would set our air fryer apart, such as a programmable timer, a non-stick cooking surface, and a user-friendly interface.

The next step was to develop prototypes that encapsulated these features. We used cutting-edge 3D printing technology to create multiple iterations, allowing us to quickly test and refine the design. Each prototype was evaluated for its ease of use, efficiency, and overall aesthetic appeal.

As we progressed, we paid close attention to the materials used, ensuring that they were not only durable but also safe for food contact. We selected high-quality stainless steel for the exterior, which not only looked premium but also maintained its integrity over time. The interior, including the basket and cooking surface, was made from a food-grade, non-stick material that was both easy to clean and resistant to wear.

Throughout the development process, we remained in constant communication with the client, providing updates and seeking their feedback. This collaboration was crucial in fine-tuning the product to meet their exact specifications. The end result was an air fryer that not only looked great but also performed exceptionally well.

Another case study involves a client looking to expand their product line into the health-conscious market. They wanted an air fryer that could offer the same crispy texture as traditional fried foods but with significantly less oil and fewer calories.

We began by analyzing the current air fryer market and identifying the key factors that influenced consumer choice. We then developed a new model with a larger capacity to accommodate family-sized portions and a unique feature that allowed for variable temperature control, enabling users to achieve the perfect crispiness with minimal oil.

To ensure the product was as energy-efficient as possible, we incorporated advanced insulation technology and a highly efficient heating element. We also designed the air fryer to be quiet and user-friendly, with a clear display and intuitive controls.

Upon completion, the client’s new air fryer received glowing reviews from both consumers and industry experts. The product’s ability to deliver delicious, healthier fried foods without compromising on taste or convenience was a significant factor in its success.

In yet another instance, a client wanted to create an eco-friendly air fryer that would appeal to environmentally conscious consumers. We focused on using sustainable materials for the construction of the fryer, including bamboo for the exterior and recycled plastics for the interior components.

We also designed the air fryer to be easily recyclable at the end of its lifespan, ensuring that it left a minimal environmental footprint. The product was marketed as a “green” alternative to traditional cooking methods, and it quickly became a favorite among eco-conscious consumers.

These case studies illustrate the meticulous process we undertake to transform ideas into high-quality, market-ready air fryers. From initial concept to final product, every step is carefully considered to ensure that the end result meets the unique requirements of our clients and their customers. Our commitment to innovation, quality, and customer satisfaction has led to a string of successful collaborations that continue to set new standards in the air fryer industry.

In today’s rapidly evolving kitchen appliances market, embracing the future with Chinese Original Design Manufacturers (ODMs) is not just a choice; it’s a strategic move. The journey from concept to the finished product, especially for a 30-day air fryer, is a testament to the innovation and precision that ODMs bring to the table. Here are some insights into the final stretch of this journey, reflecting on the culmination of our efforts to bring cutting-edge air fryers to life.

The design phase for our 30-day air fryers is a collaborative effort that blends creativity with practicality. It starts with market research to understand consumer needs and preferences, ensuring that the air fryer isn’t just a trendsetter but a solution to real-life cooking challenges. We focus on user-friendly interfaces, efficient energy use, and durable materials to create a product that stands out in the crowded kitchen appliance market.

Throughout the development process, we emphasize the importance of innovation. This isn’t just about introducing new features; it’s about making these features seamlessly integrate into the user experience. For instance, we’ve incorporated smart technology that allows the air fryer to adapt its cooking time and temperature based on the type of food being prepared. This not only enhances the cooking process but also ensures consistent results.

Quality assurance is a non-negotiable part of our process. Every component that goes into our 30-day air fryers is rigorously tested to meet the highest standards. From the electrical components to the cooking basket, every piece must perform as expected, and any inconsistencies are rectified before the product reaches the market. This meticulous approach guarantees that our customers receive a product that is reliable and long-lasting.

The production phase is where the magic happens. We’ve optimized our manufacturing processes to ensure efficiency without compromising on quality. Advanced machinery and skilled labor work in tandem to assemble the air fryers, with a keen eye on minimizing waste and maximizing output. This streamlined approach not only reduces costs but also ensures that we can meet tight production schedules.

Once the physical product is ready, it’s time to think about how it will be received by the market. Our marketing team collaborates closely with our engineers and designers to develop a compelling story for our 30-day air fryers. We focus on the unique selling points and position the product as a game-changer in the health-conscious cooking revolution.

Customer feedback is invaluable, and we actively seek it out. Through focus groups, surveys, and direct communication, we gather insights into what works and what doesn’t. This iterative process allows us to continuously refine our product, making it even more appealing to our target audience.

One of the key reasons we choose to work with Chinese ODMs is their cost-effectiveness. They offer a balance between quality and affordability, which is crucial for us to deliver a competitive product. The local supply chain is robust, allowing for quick access to parts and components, which in turn speeds up the production timeline.

Innovation is not just about introducing new products; it’s also about reimagining existing ones. Our 30-day air fryers are a prime example of how we’ve taken a familiar kitchen appliance and transformed it into a must-have item for health-conscious consumers. The design reflects a deep understanding of consumer lifestyles, focusing on ease of use, versatility, and health benefits.

Our ODM partners in China have played a pivotal role in this transformation. Their expertise in manufacturing, combined with their willingness to collaborate and innovate, has been instrumental in bringing our vision to life. They’ve not only produced a high-quality product but have also provided valuable insights into manufacturing processes and market trends.

As we reflect on the success stories of our custom air fryer ODM services, we’re reminded of the importance of staying ahead in the market. It’s not just about producing a 30-day air fryer; it’s about creating a product that resonates with consumers and addresses their needs. By continually refining our approach, we ensure that our products remain relevant and competitive.

In conclusion, the journey from concept to a fully realized 30-day air fryer is a complex and multifaceted process. It involves innovation, quality control, strategic partnerships, and a deep understanding of the market. By embracing the future of kitchen appliances with Chinese ODMs, we’ve been able to produce a product that not only meets but exceeds consumer expectations. As we look to the future, we’re excited about the potential to continue pushing the boundaries of what’s possible in kitchen appliances.