Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In a world where culinary innovation meets consumer demand, the air fryer has emerged as a beacon of change in the kitchen appliance industry. This compact, efficient cooking gadget has not only transformed the way we prepare our meals but has also sparked a wave of creativity and customization in the market. As we delve into the intricacies of OEM air fryer mold making services, it becomes clear that the future of air fryers is not just about cooking; it’s about crafting experiences that resonate with both chefs and home cooks alike.

Air fryers have quietly but steadily transformed the culinary landscape, becoming a game-changer in the world of kitchen appliances. Once a niche product, these devices have now found their way into countless homes, reshaping the way we cook and eat. The rise of air fryers can be attributed to several key factors that have made them an indispensable tool for health-conscious consumers and busy chefs alike.

The allure of air frying lies in its ability to mimic the crispy texture of fried foods without the guilt. By using hot air to circulate around the food, air fryers achieve a similar golden-brown finish while reducing the oil content significantly. This breakthrough in technology has sparked a wave of interest among consumers looking to enjoy their favorite fried treats with a lighter footprint on their health.

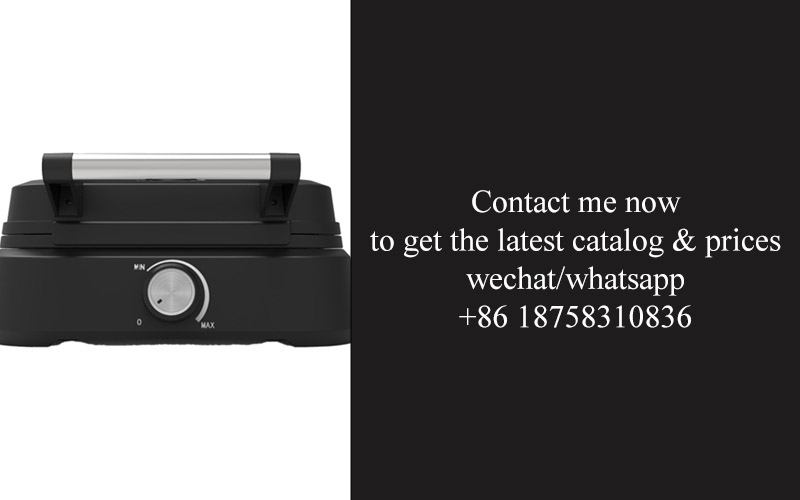

The convenience factor cannot be overstated. Air fryers are compact and easy to use, requiring minimal clean-up compared to traditional deep fryers. Their versatility is another selling point; they can be used to roast, bake, grill, and even dehydrate food. This multi-functional nature has made them a must-have for anyone seeking to simplify their cooking routine.

In recent years, there has been a surge in the demand for healthier cooking methods, and air fryers have capitalized on this trend. With the growing awareness of the health risks associated with excessive oil consumption, air fryers offer a healthier alternative that still delivers the satisfaction of crispy, flavorful dishes. This has not gone unnoticed by health and wellness influencers, who have been instrumental in promoting air fryers to a wider audience.

From a market perspective, the air fryer industry has seen rapid growth, with sales projected to continue rising. The convenience, health benefits, and cost-effectiveness of air fryers have made them a staple in kitchen stores worldwide. Moreover, the trend of home cooking has been reinforced by the global pandemic, as people seek to prepare meals at home more often.

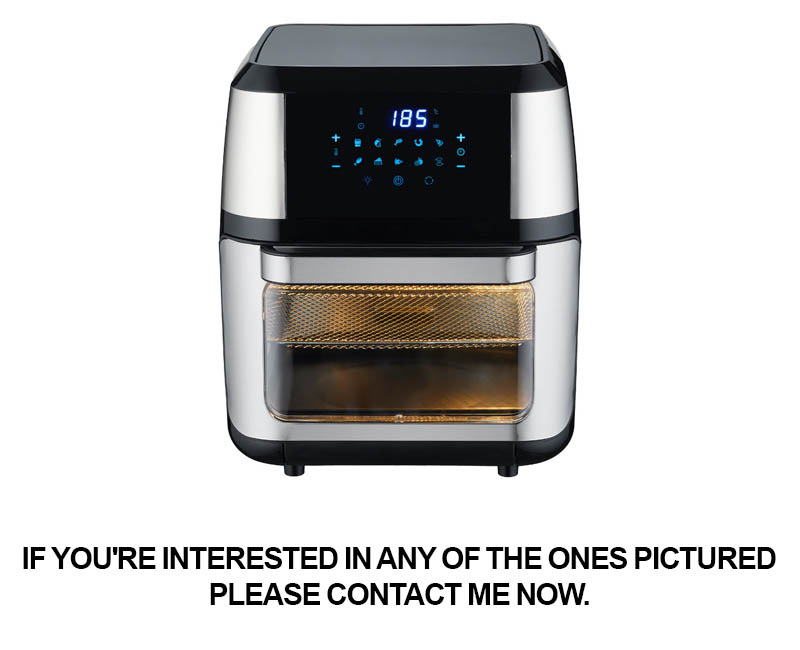

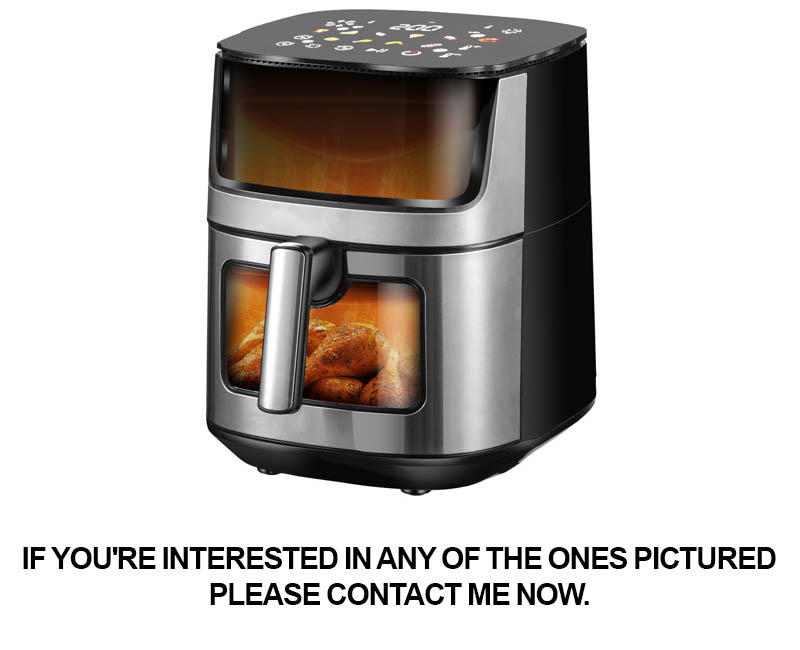

Manufacturers have responded to this demand by introducing a wide array of air fryer models, each with its unique features and capabilities. Some are designed for quick and easy use, while others offer programmable settings for gourmet-level cooking. The variety in the market has also led to innovation, with brands pushing the boundaries of what air fryers can do, from incorporating smart technology to enhancing their aesthetic appeal.

The environmental benefits of air fryers are also a compelling reason for their rise. By reducing the amount of oil needed, air fryers contribute to a decrease in plastic waste from oil containers and a reduction in greenhouse gas emissions associated with the production and transportation of oil. This eco-conscious aspect resonates with consumers who are increasingly aware of their environmental impact.

Moreover, the global trend towards convenience cooking has been a catalyst for the air fryer’s success. As people’s lives become more fast-paced, the demand for quick and efficient cooking solutions has grown. Air fryers fit this need perfectly, offering a quick and easy way to prepare a meal without compromising on taste or quality.

In the realm of professional kitchens, air fryers have also gained popularity. Chefs are turning to these appliances for their ability to cook large quantities of food in a shorter time, while maintaining the integrity of the ingredients. The commercial-grade models available today are robust, reliable, and capable of handling the demands of a busy kitchen.

The rise of air fryers as a game-changer in kitchen appliances is a testament to the power of innovation and consumer demand. As technology continues to evolve, we can expect even more sophisticated air fryer models that cater to the diverse needs of today’s consumers. Whether you’re a health-conscious home chef or a busy professional, the air fryer has become an indispensable tool that is reshaping the way we cook, one crispy morsel at a time.

In today’s rapidly evolving kitchen appliance market, Original Equipment Manufacturing (OEM) has emerged as a pivotal strategy for brands looking to expand their global reach. This section delves into the intricacies of the OEM market and how it offers tailored solutions for global brands.

The OEM market is a world where innovation meets collaboration. It’s a landscape where manufacturers don’t just produce products; they create custom solutions that align with the brand’s vision and market strategy. For global brands, this means having the flexibility to introduce new products that resonate with diverse consumer bases across the globe.

One of the key advantages of the OEM market is the ability to offer a unique value proposition. Brands can leverage the expertise of OEM partners to develop appliances that are not only cutting-edge but also cater to specific regional preferences and regulatory standards. Whether it’s adapting to different voltage systems or incorporating local ingredients into cooking modes, OEM solutions ensure that the product is not only functional but also culturally relevant.

Customization is king in the OEM market. Brands can dictate everything from the design of the appliance to the internal components, ensuring that the final product reflects their brand identity and values. This level of control allows for a more cohesive product line that stands out in a crowded market, with features that are both functional and aesthetically pleasing.

The OEM process also fosters a symbiotic relationship between manufacturers and brands. OEM partners often have a deep understanding of the supply chain, from raw materials to manufacturing processes, which can be leveraged to optimize costs and ensure quality. This collaboration means that brands can focus on marketing and brand building, while the OEM takes care of the technical and production aspects.

For global brands, entering new markets can be daunting due to varying consumer behaviors and preferences. The OEM market provides a bridge, allowing brands to test the waters with localized products that are less risky than a full-scale product launch. This trial-and-error approach can be invaluable in understanding what works and what doesn’t in different regions.

Moreover, the OEM market offers scalability. Brands can start with a limited production run to gauge market response, and if successful, scale up production without the need for significant upfront investment. This agility is crucial in a market where consumer trends can shift rapidly.

Innovation is another cornerstone of the OEM market. Brands can tap into the latest technological advancements through their OEM partners, ensuring that their products remain at the forefront of the market. From energy-efficient designs to smart kitchen integration, OEM solutions can incorporate features that not only enhance the user experience but also position the brand as a leader in innovation.

When it comes to sustainability, the OEM market plays a crucial role. Brands can work with manufacturers to create appliances that are not only eco-friendly but also have a minimal carbon footprint. This focus on sustainability is increasingly important to consumers and can be a significant differentiator in the market.

Lastly, the OEM market provides a platform for collaboration and knowledge sharing. Brands can gain insights into the latest industry trends and consumer demands from their partners, which can inform future product development. This exchange of ideas can lead to breakthroughs that might not have been possible working in isolation.

In summary, the OEM market is a dynamic and multifaceted ecosystem that offers tailored solutions for global brands. By partnering with OEM manufacturers, brands can achieve a competitive edge through customization, innovation, and a deep understanding of global consumer needs. Whether it’s entering new markets, scaling up production, or staying ahead of the curve, the OEM market is a strategic ally for brands aiming to make their mark on the global stage.

In the world of kitchen appliances, the art of mold making is a critical component that shapes the production of air fryers. This intricate process combines precision engineering with innovative design to ensure that each air fryer is not just a functional product but also a testament to the craftsmanship behind it.

The journey begins with the selection of the right materials. High-quality aluminum, stainless steel, or even BPA-free plastics are chosen for their durability and safety. These materials must withstand the high temperatures and pressures of the cooking process while also being easy to clean and maintain.

Once the material is chosen, the design phase kicks in. Molds are meticulously crafted to reflect the intricate designs and specifications of the air fryer. CAD (Computer-Aided Design) software is often used to create a digital blueprint that can be translated into a physical mold. This step is crucial, as the accuracy of the mold will directly impact the quality of the final product.

The mold making process itself is a blend of art and science. It involves the creation of a negative shape that will be used to cast the air fryer components. The mold is typically made from a durable material like steel or aluminum, which can withstand the heat and pressure of the casting process. The mold is then polished to ensure a smooth surface, which is essential for the quality of the finished product.

The next step is the injection molding process. Molten plastic or metal is injected into the mold under high pressure. The material fills the mold cavity, taking the shape of the desired air fryer part. The speed and pressure during this phase are critical, as they determine the strength and finish of the final product.

Precision is paramount in mold making. Even the smallest imperfection can lead to defects in the air fryer. That’s why quality control is integrated throughout the process. Engineers use sophisticated measurement tools to check the mold’s dimensions and ensure that it meets the exacting standards required for high-quality air fryer production.

Innovation plays a significant role in mold making. Advances in technology have allowed for the creation of molds with complex geometries and intricate features that were once impossible to achieve. This means that air fryer manufacturers can design more efficient and aesthetically pleasing products. For example, molds can now incorporate features that enhance heat distribution, making the cooking process more effective and the end product healthier.

Another aspect of innovation is the use of advanced materials. For instance, molds made with composite materials can offer a better balance of strength and flexibility, which is particularly important for the moving parts of an air fryer. These materials can also reduce the weight of the air fryer without compromising its structural integrity.

The mold making process is not just about creating a mold that can produce a functional air fryer. It’s also about ensuring that the mold can be used repeatedly without wearing down. This longevity is achieved through proper maintenance and regular inspections. Any signs of wear or damage are addressed promptly to prevent production issues.

Lastly, sustainability is a growing concern in the mold making industry. Manufacturers are increasingly looking for ways to reduce waste and energy consumption in the mold making process. This includes using recycled materials for molds and optimizing production techniques to minimize environmental impact.

In conclusion, the art of mold making in air fryer production is a complex and highly skilled endeavor. It requires a deep understanding of materials, design, and engineering, as well as a commitment to quality and innovation. By mastering this art, manufacturers can deliver air fryers that not only meet the demands of the market but also exceed consumer expectations.

Our mold making service stands out in the OEM air fryer market for several compelling reasons. Here’s why you should consider us for your custom air fryer production needs:

Innovative Design CapabilitiesOur team of skilled engineers and designers thrives on innovation. We understand that the key to a successful air fryer lies in its design, both in terms of functionality and aesthetics. We offer cutting-edge design solutions that not only enhance the performance of the air fryer but also appeal to the modern consumer’s desire for sleek, modern appliances.

Precision EngineeringPrecision is paramount in the mold making process, especially for air fryers where every millimeter can impact efficiency and safety. We pride ourselves on our precision engineering, ensuring that every mold we create is accurate to the smallest detail. This level of precision translates into air fryers that meet the highest quality standards.

Advanced Materials and TechniquesThe choice of materials and the techniques used in mold making can significantly affect the longevity and performance of the final product. We are well-versed in using high-quality materials that are durable, heat-resistant, and non-toxic, ensuring that the air fryers we mold are not only efficient but also safe for users. Our advanced techniques include CNC machining, which allows for intricate details and tight tolerances.

Customization for Your BrandWe recognize that each brand has its unique identity and product requirements. That’s why our mold making service is highly customizable. Whether you need a specific size, shape, or feature for your air fryer, we can tailor the mold to your exact specifications. This level of customization helps you differentiate your product in a crowded market.

Rapid PrototypingTime-to-market is crucial in the fast-paced appliance industry. Our rapid prototyping capabilities mean we can quickly turn your design into a physical prototype. This not only speeds up the development process but also allows for early testing and refinement before full-scale production begins.

Quality AssuranceWe take quality assurance seriously. Every mold we produce undergoes rigorous testing to ensure it meets our high standards. This includes checking for any defects, ensuring the mold’s surface finish is up to par, and verifying that it can withstand the necessary pressures and temperatures required for air fryer production.

Global Reach and ExperienceOur mold making service has a global footprint, working with brands from all corners of the world. This experience has given us a deep understanding of international markets and regulations. We know the ins and outs of shipping, certifications, and compliance, making us a reliable partner for companies looking to expand into new markets.

Competitive PricingWhile we never compromise on quality, we also understand the importance of cost-effectiveness. Our pricing is competitive without sacrificing the quality of our mold making service. We offer transparent pricing and can work within your budget constraints to find the best solution for your air fryer production needs.

Sustainability FocusIn an era where sustainability is a growing concern, we’ve integrated eco-friendly practices into our mold making process. We use sustainable materials and strive to minimize waste throughout production. This commitment aligns with the values of many brands and consumers today.

Excellent Customer ServiceOur customer service is second to none. We maintain open lines of communication with our clients, ensuring that their needs and expectations are met at every stage of the mold making process. From initial consultations to post-production support, we are here to help you every step of the way.

By choosing our mold making service for your OEM air fryers, you’re not just selecting a service provider; you’re investing in a partner that is dedicated to your brand’s success, driven by innovation, and committed to delivering excellence in every aspect of air fryer production.

Navigating through the intricacies of the air fryer production process, our mold-making service stands out for its meticulous approach and commitment to excellence. Here’s an in-depth look at our process, from the initial concept to the delivery of a custom-made air fryer.

The Conceptualization PhaseOur journey begins with a blank canvas—a concept for a new air fryer design. We collaborate closely with our clients, ensuring that their vision is not only understood but also enhanced with our expertise. This phase involves brainstorming sessions, sketching ideas, and feasibility studies to gauge the practicality and market potential of the proposed design.

Design RefinementOnce the concept is approved, the design team dives into the refinement process. This is where CAD (Computer-Aided Design) software becomes invaluable. We meticulously craft the air fryer’s design, focusing on ergonomics, safety features, and aesthetic appeal. The design is then subjected to stress testing and simulation to ensure it can withstand the rigors of daily use.

Material SelectionChoosing the right materials is crucial for both the functionality and the longevity of the air fryer. Our team evaluates various materials, considering factors like heat resistance, durability, and recyclability. We prioritize materials that not only meet industry standards but also align with our clients’ sustainability goals.

Mold Design and PrototypingThe heart of our process lies in the mold design. Each mold is a precision instrument, and its accuracy can make or break the final product. We use advanced CAD and CAM (Computer-Aided Manufacturing) systems to create detailed mold designs. These molds are then used to produce prototypes, which are essential for testing and validation.

Prototype TestingBefore moving forward, we rigorously test the prototypes. This phase involves physical testing to ensure the air fryer meets all safety and performance standards. We subject the prototypes to extreme conditions, such as high temperatures and rapid pressure changes, to simulate real-world usage scenarios.

Iterative ImprovementsBased on the test results, we make necessary adjustments to the design and mold. This iterative process continues until the prototype meets our stringent quality standards. It’s a balance of art and science, where every detail is scrutinized to ensure the final product is not just functional but also a joy to use.

Mold ProductionOnce the design is finalized, we move on to mold production. This is a complex process that requires precision and skill. We use high-quality steel and advanced machining techniques to create molds that are durable and capable of producing thousands of air fryers without losing their accuracy.

Quality AssuranceThroughout the mold-making process, quality assurance is paramount. We employ state-of-the-art inspection equipment to monitor the quality of each mold. This includes checking the mold’s surface finish, dimensional accuracy, and the tightness of the mold cavities.

Tooling and AssemblyWith the mold ready, we move to the tooling phase. This involves setting up the molds in the injection molding machines and fine-tuning them for optimal performance. The assembly process is then initiated, where all the components of the air fryer are brought together with precision.

Final Product TestingBefore shipping, each custom-made air fryer undergoes a final round of testing. This ensures that every unit meets the same high standards we’ve set for our prototypes. Only after passing these tests do we consider the product ready for market.

Delivery and Ongoing SupportFinally, we deliver the custom-made air fryers to our clients, complete with documentation and technical support. Our relationship doesn’t end with delivery; we offer ongoing support, ready to address any issues or make improvements as needed.

In summary, our process is a testament to our dedication to quality and innovation. From concept to custom-made air fryer, we ensure that every step is carefully executed, resulting in a product that not only meets but exceeds expectations.

In today’s competitive market, the ability to offer customized products is a game-changer. Customization isn’t just about meeting customer needs; it’s about crafting an experience that resonates with their desires and expectations. When it comes to OEM air fryers, the benefits of customization are multifaceted, enhancing brand identity and market appeal in several compelling ways.

The Power of Personal TouchCustomers are no longer satisfied with one-size-fits-all solutions. They seek products that reflect their personal style and preferences. Customizing an air fryer allows brands to cater to these unique tastes, offering a level of personalization that can create a lasting impression. From the design of the fryer to the branding and features, every detail can be tailored to stand out in the consumer’s mind.

Building Strong Brand IdentityA brand’s identity is its soul, and customization is a powerful tool for reinforcing this identity. When a company invests in customizing its OEM air fryers, it sends a clear message about its commitment to quality, innovation, and customer satisfaction. This bespoke approach helps to distinguish the brand from its competitors, making it more memorable and trusted by consumers.

Enhancing Market AppealThe market is flooded with generic products, making it difficult for brands to stand out. Customization breathes new life into products, making them more attractive to consumers. A unique design or innovative feature can be the deciding factor that drives potential buyers to choose one brand over another. By offering a custom-made air fryer, brands can tap into the niche markets and capture the attention of specific customer segments.

Tailoring to Specific DemandsEvery market has its own set of demands and challenges. Customization allows brands to address these specific needs effectively. Whether it’s adapting the air fryer for different power sources, incorporating local ingredients, or ensuring compliance with regional safety standards, a customized approach ensures that the product is well-suited for the target market.

Innovation Through CollaborationCustomization isn’t just about modifying existing products; it’s about fostering innovation. When brands work closely with mold making services, they open the door to new ideas and technologies. This collaborative process can lead to the development of cutting-edge air fryers that not only meet but exceed customer expectations.

Creating a NarrativeCustomization can help create a narrative around a brand. A unique and customized air fryer can tell a story about the brand’s values, heritage, or mission. This narrative can resonate with consumers on an emotional level, fostering a deeper connection and loyalty to the brand.

Reducing Time to MarketIn the fast-paced world of consumer electronics, time to market is crucial. Customization services can streamline the production process, allowing brands to bring their custom-made air fryers to market faster. This agility is especially valuable in capturing trends and staying ahead of the competition.

Cost-Effective SolutionsContrary to popular belief, customization doesn’t have to be expensive. Advanced mold making techniques and efficient production processes can ensure that custom solutions are cost-effective without compromising on quality. This allows brands to offer premium products at competitive prices.

Customer Satisfaction Through QualityUltimately, the most significant benefit of customization is the impact it has on customer satisfaction. When customers receive a product that has been tailored to their needs, they are more likely to be satisfied with their purchase. This satisfaction translates into repeat business, positive word-of-mouth, and a strong reputation for the brand.

In the ever-evolving landscape of kitchen appliances, customization is not just an option; it’s a necessity. It’s about creating a unique selling proposition, building a strong brand identity, and appealing to the discerning tastes of today’s consumers. By choosing to customize their OEM air fryers, brands can unlock a world of possibilities that can drive growth and success in the market.

In the rapidly evolving landscape of the air fryer market, staying informed about industry trends and leveraging data-driven insights is crucial for manufacturers aiming to maintain a competitive edge. Here’s a deeper look into what’s shaping the future of air fryers:

The surge in health consciousness has propelled the demand for air fryers, as consumers seek healthier alternatives to traditional deep-frying methods. This trend is not just a passing fad but a shift in lifestyle preferences that is here to stay.

Market analysts are reporting a significant increase in the sales of air fryers across various regions. The Asia-Pacific market, in particular, is witnessing explosive growth, driven by a rising middle class and a growing awareness of healthy cooking practices.

Smart technology integration is becoming a hallmark of modern air fryers. Features like Bluetooth connectivity, which allow users to control their appliances remotely, are becoming more common. Data from user engagement with these smart features can provide valuable insights into consumer behavior and preferences.

Energy efficiency is another key trend. As consumers become more environmentally conscious, they are looking for appliances that not only save money on energy bills but also contribute to a greener planet. The latest air fryers are being designed with energy-saving technologies in mind.

The rise of eco-friendly materials is also making waves in the air fryer market. Brands that prioritize sustainability are adopting biodegradable plastics and other environmentally responsible materials in their product designs.

Consumer preferences are becoming more diverse, and this is reflected in the variety of air fryer models available. From countertop models to integrated kitchen appliances, the market is saturated with choices that cater to different needs and lifestyles.

Data from customer reviews and market research indicates a growing preference for air fryers that offer versatility. Users are looking for devices that can perform multiple functions, such as roasting, baking, and even grilling, all within the confines of an air fryer.

The air fryer market is also seeing an increase in the use of advanced heat distribution systems. Uniform heating is crucial for consistent results, and new innovations in this area are ensuring that every meal cooked in an air fryer is as delicious as the last.

As the market expands, so does the importance of compliance with safety standards and certifications. Consumers are more likely to purchase air fryers that have been independently tested and certified for safety.

Brands that are able to adapt to these trends and use data analytics to understand consumer behavior are poised to succeed. By analyzing sales data, customer feedback, and market research, companies can anticipate future demands and innovate accordingly.

In conclusion, staying ahead in the air fryer market requires a keen understanding of consumer trends, a commitment to innovation, and the ability to use data-driven insights to inform product development and marketing strategies. By keeping a pulse on these industry trends, manufacturers can ensure they remain at the forefront of this dynamic market.

In the world of OEM air fryer mold making, our service has been instrumental in crafting success stories for numerous brands. Let’s delve into a few of these tales, showcasing how our expertise has propelled our clients to the forefront of the market.

Our collaboration with a leading global kitchen appliance brand began with a simple yet ambitious request: to revolutionize the air fryer design. The client envisioned a sleek, modern model that would appeal to health-conscious consumers. Our mold-making team meticulously crafted a prototype that not only met but exceeded expectations. The result was an air fryer that not only looked stunning but also performed exceptionally well, capturing the attention of consumers worldwide.

Another case study involves a mid-sized manufacturer looking to differentiate its product line from the competition. They approached us with a unique concept: an air fryer that could be used both in the kitchen and as a countertop decor piece. Our engineers worked closely with the client to develop a mold that would allow for intricate details and a seamless transition from a functional appliance to a stylish addition to any kitchen. The final product was a hit, not just for its functionality but also for its aesthetic appeal, which helped the brand stand out in a crowded market.

We’ve also had the pleasure of working with a startup that wanted to enter the air fryer market with a bang. The founders had a vision for a compact, portable air fryer that could be easily transported and used on the go. Our mold-making service provided the precision needed to create a mold that would produce a unit with a sturdy yet lightweight design. The end product was a game-changer for the startup, as it quickly gained a loyal following among busy professionals and travelers.

One of our most challenging projects involved a client who wanted to integrate smart technology into their air fryer design. The challenge was to ensure that the mold would accommodate the electronics without compromising the fryer’s performance or safety. Our team of experts rose to the occasion, developing a mold that allowed for precise placement of the smart components while maintaining the integrity of the air fryer’s structure. The final product was a smart air fryer that not only performed well but also offered a seamless user experience, which was crucial for the client’s brand identity.

In another instance, a well-established brand approached us with a request to upgrade their existing air fryer line. They sought a mold that would enable them to produce a model with a unique, curved design that would be both visually appealing and functional. Our mold-making service delivered, ensuring that the new design not only looked innovative but also maintained the efficiency and safety of the air fryer. The updated product line was a resounding success, helping the brand maintain its competitive edge.

We’ve also had the opportunity to work with a company that specializes in eco-friendly products. Their goal was to create an air fryer that was not only energy-efficient but also made from sustainable materials. Our mold-making process was tailored to accommodate the unique requirements of the product, ensuring that the mold could handle the necessary changes without compromising the fryer’s performance. The resulting air fryer was a testament to the brand’s commitment to sustainability, and it resonated with environmentally conscious consumers.

These case studies highlight the versatility and expertise of our mold-making service in the OEM air fryer market. From startups to established brands, our solutions have been pivotal in helping clients achieve their design and market goals. Whether it’s through innovative designs, smart technology integration, or eco-friendly manufacturing, our service has been a cornerstone in crafting successful air fryer products that stand out in a competitive landscape.

The evolution of air fryers has been nothing short of remarkable. From their inception as a healthier alternative to deep-frying, these appliances have surged in popularity, becoming a staple in modern kitchens worldwide. As we look to the future, the industry is poised for even more innovation and groundbreaking advancements. Here are some of the potential directions air fryers might take in the coming years.

In the realm of technology, we can expect a fusion of smart home integration. Air fryers of the future might be equipped with IoT capabilities, allowing users to control their cooking processes remotely through smartphone apps. Imagine being able to monitor your air fryer while at work or on vacation, adjusting settings to ensure your food is perfectly cooked upon your return.

Energy efficiency is another area that’s ripe for improvement. As environmental concerns grow, air fryers that consume less electricity and operate more sustainably will become increasingly popular. Innovations like heat recovery systems could reduce energy waste, making air fryers a greener choice for eco-conscious consumers.

Materials science will play a crucial role in shaping the future of air fryers. Advances in non-stick coatings could lead to longer-lasting appliances that require less maintenance. Additionally, the use of lightweight, durable materials might make air fryers more portable and easier to store, especially in smaller urban apartments.

Health and wellness are at the forefront of consumer concerns, and air fryers are already a healthier cooking option. The future could see a rise in air fryers that offer even more health benefits, such as built-in air purification systems that filter out cooking odors and improve air quality in the kitchen.

Sustainability is also a growing concern, and the air fryer industry might respond with eco-friendly designs. This could include the use of recycled materials for manufacturing, packaging made from biodegradable materials, and a focus on the appliance’s end-of-life recycling process.

Personalization will continue to be a key trend. Users might see air fryers that come with a range of attachments and accessories, allowing for a variety of cooking methods beyond the traditional air frying. This could include attachments for grilling, roasting, or even baking.

The rise of plant-based diets has sparked interest in air fryers that can cater to these preferences. We may see models specifically designed for cooking vegetables, tofu, and other plant-based ingredients, with settings optimized for the unique needs of these foods.

Safety features are always a priority, and future air fryers could include advanced safety mechanisms such as automatic shut-off after a set time, child locks to prevent accidental use, and thermal sensors to prevent overheating.

In terms of design, air fryers might take a cue from the tech industry’s sleek, minimalist aesthetics. We could see more modern, sleek designs that blend seamlessly into kitchen countertops and cabinets.

Branding and marketing will also play a significant role in the future of air fryers. As the market becomes more saturated, brands will need to differentiate themselves through innovative features, unique selling propositions, and compelling storytelling.

Finally, the air fryer industry will need to adapt to changing global trends. As consumer preferences vary across different regions, companies will have to tailor their products to meet the specific needs and tastes of different markets.

The future of air fryers is exciting, filled with possibilities for technological advancements, health-conscious features, and sustainability initiatives. As the industry continues to evolve, one thing is certain: the air fryer will remain a versatile and popular kitchen appliance, ready to meet the ever-changing demands of the modern consumer.

Navigating the intricate landscape of the air fryer market, it’s clear that innovation and collaboration are key to staying competitive. As a brand, finding the right partner for your OEM air fryer mold making service can be the difference between a product that meets expectations and one that exceeds them. Here’s why you should consider us as your go-to innovation partner:

Precision Engineering: Our team of skilled mold makers brings a wealth of experience to the table, ensuring that every detail of your air fryer design is translated into a functional and durable mold. From intricate designs to seamless transitions, we pride ourselves on the precision that sets our work apart.

Material Expertise: The choice of materials is critical in the air fryer industry, where heat resistance and durability are paramount. We understand the nuances of various materials and can recommend the best options to enhance both the performance and longevity of your product.

Customization Flexibility: We offer a wide range of customization options, from size and shape to specialized features. Whether you’re looking to incorporate new technologies or simply refine an existing design, our flexible approach allows us to tailor our mold making service to your specific needs.

Rapid Prototyping: Time-to-market is crucial in today’s fast-paced consumer electronics market. Our rapid prototyping capabilities mean you can get your hands on a functional air fryer prototype quickly, allowing for timely feedback and adjustments before full-scale production.

Quality Assurance: We don’t just stop at creating molds; we also ensure they meet the highest quality standards. Our rigorous testing protocols guarantee that your air fryers will perform as expected, reducing the risk of product recalls and enhancing customer satisfaction.

Cost-Effective Solutions: While quality is non-negotiable, we understand the importance of cost-effectiveness. Our efficient production processes and economies of scale enable us to offer competitive pricing without compromising on the quality of our mold making service.

Sustainable Practices: As an environmentally conscious company, we are committed to sustainable practices. Our mold making service incorporates eco-friendly materials and methods, reducing waste and minimizing our carbon footprint.

Collaborative Approach: We believe in a collaborative partnership where your vision is at the forefront. Our team works closely with you throughout the process, providing expert advice and creative solutions that align with your brand’s identity and market strategy.

Global Reach: Whether you’re targeting local markets or expanding internationally, we have the global reach to support your air fryer mold making needs. Our network of suppliers and manufacturers ensures that your product can be produced efficiently and delivered to any corner of the world.

Continuous Improvement: The air fryer market is always evolving, and we stay at the forefront of these changes. Our commitment to continuous improvement means we’re always looking for new ways to innovate and improve our mold making service, keeping your brand ahead of the curve.

If you’re ready to elevate your air fryer product and take it to new heights, look no further. Contact us today, and let’s embark on a journey of innovation together. Your success is our mission, and we’re here to help you achieve it. From concept to custom-made air fryer, we’re your dedicated partner in pushing the boundaries of what’s possible in the industry.