Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving landscape of kitchen appliances, the industrial waffle maker has emerged as a versatile and sought-after tool for both commercial and domestic settings. As the demand for high-quality, efficient, and innovative waffle-making solutions grows, the industry is witnessing a surge in professional-grade waffle makers, particularly those designed for use with the 220V standard. This article delves into the key features, consumer demands, successful case studies, industry challenges, opportunities, and future prospects of these industrial waffle makers, shedding light on their significant impact on the kitchen appliances industry.

The industrial waffle maker market has quietly emerged as a cornerstone in the culinary equipment industry, offering a unique blend of innovation and practicality. These machines are not just your average kitchen gadgets; they are designed to cater to the demands of commercial kitchens, catering services, and even high-volume home cooks. As we delve into this specialized niche, it’s clear that the industrial waffle maker market is a dynamic and evolving sector.

Waffles, once a beloved breakfast staple, have now transcended breakfast tables to become a versatile and trendy food item. From breakfast cafes to gourmet restaurants, the demand for freshly made waffles has surged. This surge has, in turn, fueled the growth of the industrial waffle maker market, which is now witnessing a proliferation of advanced and high-capacity models.

The market is segmented by various factors, including the type of waffle design, the source of power, and the intended use. Among these, the 220V industrial waffle maker stands out as a favorite in Europe and the United States, where this voltage standard is widely adopted. These machines are designed to handle the rigors of continuous use, providing consistent results in a variety of settings.

One of the key drivers of the industrial waffle maker market is the emphasis on quality and efficiency. These machines are engineered to produce professional-grade waffles in a fraction of the time it would take to make them by hand. This efficiency is particularly appealing to busy kitchens looking to maximize their output while maintaining high-quality standards.

Moreover, the market is witnessing a shift towards healthier eating habits. Consumers are increasingly seeking out lighter, whole-grain waffles, and the industrial waffle makers are adapting by offering healthier alternatives. From gluten-free to high-protein, these machines can accommodate a wide range of dietary needs, making them a versatile addition to any kitchen.

Innovation is another driving force behind the growth of the industrial waffle maker market. Manufacturers are constantly pushing the boundaries with new features and functionalities. From non-stick surfaces that ensure easy release of waffles to programmable settings that allow for precise temperature control, these machines are becoming more sophisticated with each new model.

The design of industrial waffle makers has also evolved to cater to the needs of diverse kitchen environments. Compact models are now available for limited space kitchens, while larger, multi-functional units can handle high-volume production in busy restaurants. The variety of shapes and sizes available allows chefs to create everything from classic Belgian waffles to heart-shaped or even novelty waffles for special occasions.

As the market grows, so does the competition. Established players are constantly innovating and introducing new products, while new entrants are bringing fresh ideas to the table. This competition has led to a wider range of options for consumers, ensuring that there’s a machine to suit every need and budget.

However, the market is not without its challenges. Energy efficiency and sustainability are increasingly important considerations for consumers and businesses alike. Manufacturers are responding by developing waffle makers that consume less energy and are made from recyclable materials, aligning with the broader environmental movement.

In conclusion, the industrial waffle maker market is a vibrant and rapidly growing sector within the culinary equipment industry. With a focus on innovation, efficiency, and adaptability, these machines are becoming an indispensable tool for chefs and foodservice professionals. As the market continues to evolve, it will be fascinating to see how industrial waffle makers continue to shape the world of waffle-making and culinary innovation.

The 220V standard has long been a cornerstone of electrical systems in Europe and the United States, shaping the landscape of consumer electronics and appliances. In the realm of industrial waffle makers, this voltage specification has emerged as a pivotal factor, driving innovation and efficiency. Understanding the significance of the 220V standard is crucial for anyone seeking to navigate the European and American markets for these versatile kitchen appliances.

The 220V electrical system is characterized by its higher voltage compared to other global standards, such as the 110V systems found in North America. This difference in voltage directly impacts the design, performance, and compatibility of industrial waffle makers. In Europe and the US, appliances designed for 220V operate at a higher power output, which translates to faster and more consistent waffle production.

One of the primary advantages of the 220V standard is its ability to deliver a more robust and powerful performance. Industrial waffle makers designed for this voltage can handle higher loads, allowing for the production of larger batches of waffles in a shorter amount of time. This is particularly beneficial for commercial kitchens, cafes, and bakeries that require a steady supply of waffles to meet customer demand.

Moreover, the 220V standard often results in appliances that are more compact and efficient. The higher voltage enables components to be downsized without sacrificing performance, leading to waffle makers that are not only powerful but also space-saving. This compact design is especially appealing in busy commercial settings where every square inch counts.

In the European and American markets, the 220V standard has also influenced the evolution of safety features in industrial waffle makers. With higher voltages come increased safety concerns, and manufacturers have responded by incorporating advanced safety mechanisms. These may include thermal cutoffs, overload protection, and double insulation to prevent electrical hazards.

The compatibility of 220V appliances is another critical aspect to consider. While Europe and the US share this voltage standard, there are still regional differences in electrical outlet types and plug configurations. For instance, in Europe, the standard plug is the Schuko, while in the US, it’s the NEMA 5-15. This means that when importing or selling 220V industrial waffle makers, manufacturers must ensure that the appliances are properly adapted to fit the local electrical infrastructure.

In terms of innovation, the 220V standard has spurred the development of new features and functionalities. For example, some models now come with programmable settings that allow users to adjust the cooking temperature and time, ensuring consistent results every time. Additionally, the higher voltage has enabled the integration of advanced heating elements that distribute heat more evenly across the waffle iron, resulting in a perfectly crisp and golden waffle.

The 220V standard has also opened doors for energy-saving technologies. As awareness of sustainability grows, manufacturers are increasingly focusing on creating waffle makers that consume less energy without compromising on performance. This not only benefits the environment but also reduces operational costs for businesses.

Another important consideration is the after-sales service and support. Given the specialized nature of industrial appliances, having a reliable service network is essential. In regions adhering to the 220V standard, manufacturers often establish partnerships with local service providers to ensure that customers receive prompt and efficient maintenance and repairs.

In conclusion, the 220V standard has become a game-changer in the industrial waffle maker market, particularly in Europe and the United States. It has influenced the design, performance, and safety of these appliances, while also driving innovation and efficiency. As the demand for high-quality, commercial-grade waffle makers continues to rise, understanding the intricacies of the 220V standard is key for both manufacturers and consumers seeking to make informed decisions in this dynamic market.

In the ever-evolving landscape of kitchen appliances, the industrial waffle maker has seen a surge in innovation. These machines, once limited to the confines of home kitchens, have now become versatile tools in commercial settings. The latest designs in industrial waffle makers are not just about producing delicious Belgian waffles; they’re about efficiency, durability, and user experience. Here’s a closer look at some of the innovative features that are shaping the future of waffle-making.

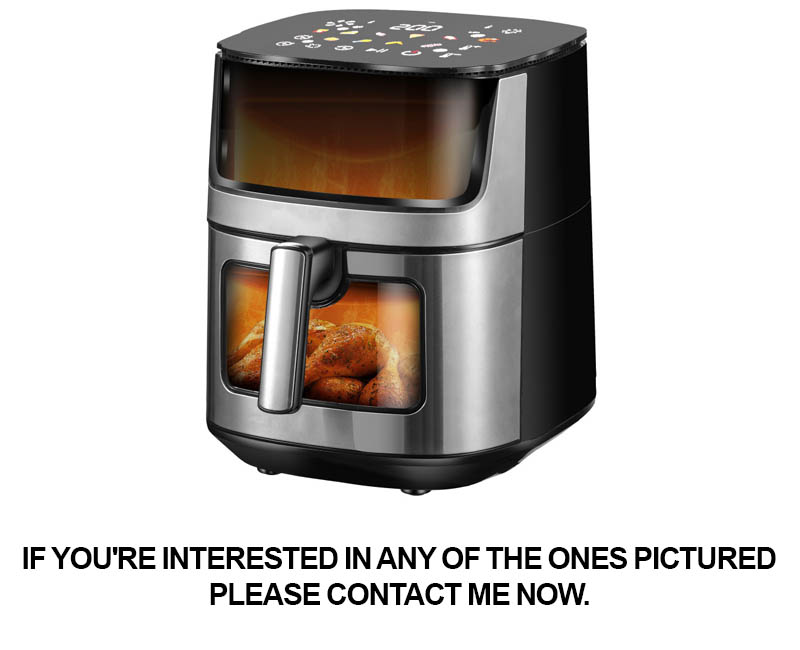

The first notable innovation is the integration of advanced heating technology. Modern industrial waffle makers often feature rapid-heat systems that can reach optimal temperatures in mere minutes. This not only ensures a consistent waffle quality but also reduces downtime, making them ideal for high-volume environments like cafes and restaurants.

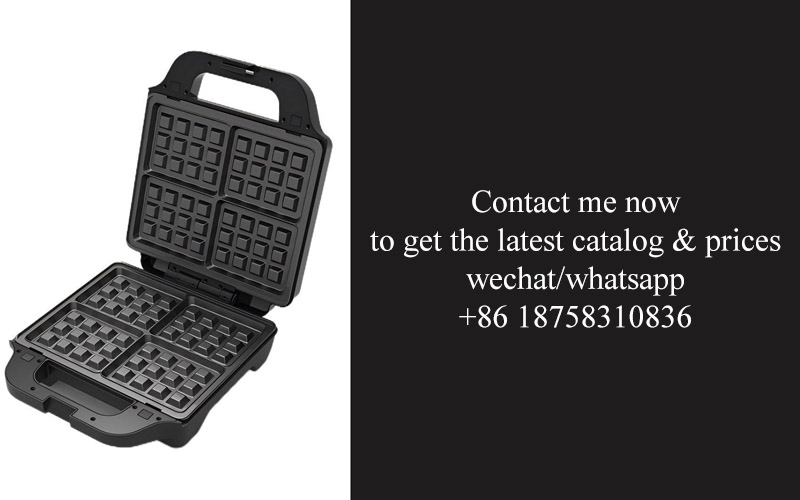

Secondly, the design of these machines has evolved to accommodate different waffle shapes and sizes. From classic Belgian waffles to heart-shaped or even customizable patterns, the variety in design allows for a diverse menu that caters to different tastes and occasions. Some models even come with interchangeable plates, making it easy for operators to switch between various waffle styles with minimal effort.

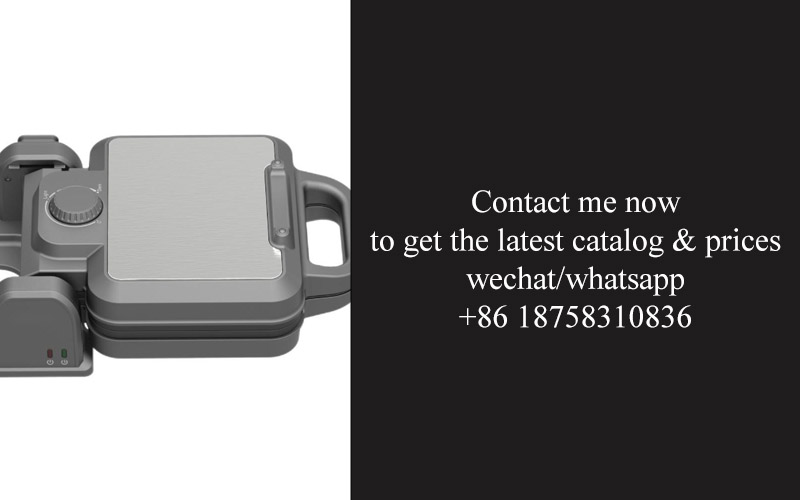

Durability is another key aspect of these innovative designs. Industrial waffle makers are built to withstand constant use, with heavy-duty materials and robust construction. The use of stainless steel and high-quality components ensures that these machines can handle the rigors of a commercial kitchen without compromising on performance.

The user interface has also seen significant advancements. Many industrial waffle makers now come with digital controls, offering precise temperature settings and timers. This level of control allows operators to achieve the perfect waffle every time, without the guesswork that often comes with manual adjustments. Some units even have built-in diagnostics that alert users to any potential issues, further enhancing reliability.

Safety features have also been a focal point in the design of modern industrial waffle makers. Features like automatic shut-off, which activate after a set period of inactivity, help prevent accidents and reduce the risk of fires. Additionally, non-slip bases and heat-resistant handles ensure that the machines are both safe and easy to use.

Efficiency is a critical factor in commercial operations, and the latest industrial waffle makers are designed with this in mind. Many models now feature energy-saving technologies that reduce power consumption without sacrificing performance. This not only helps businesses save on energy costs but also aligns with the growing demand for sustainable and eco-friendly appliances.

Innovation also extends to the ease of maintenance and cleaning. The design of these machines allows for quick and straightforward cleaning, with removable parts that are dishwasher-safe or easy to wipe down. This feature is particularly important in busy kitchens where cleanliness is paramount.

The inclusion of additional features like programmable settings and the ability to create a variety of toppings and spreads has also become common. Some models even offer a built-in griddle function, allowing operators to cook additional items like bacon or pancakes alongside waffles, maximizing output and efficiency.

Lastly, the aesthetic appeal of these industrial waffle makers should not be overlooked. With sleek designs and a range of colors available, these machines can complement the decor of any commercial kitchen, adding a touch of modernity and style to the space.

In summary, the innovation in industrial waffle makers reflects a deeper understanding of the needs of professional kitchens. From advanced heating systems and customizable designs to enhanced safety and efficiency, these machines are becoming indispensable tools for chefs and restaurateurs alike. As the industry continues to evolve, we can expect even more creative and practical solutions to emerge, ensuring that the art of waffle-making remains as dynamic and exciting as ever.

In recent years, the market for professional-grade waffle makers has experienced a significant surge, driven by a variety of factors. This rise is not just a fad but a testament to the evolving culinary landscape and the demand for high-quality, versatile appliances. Here’s a closer look at the trends shaping this sector.

The first notable trend is the increasing focus on versatility. Modern professional-grade waffle makers are not just limited to the classic Belgian waffle. They now offer a range of patterns, from intricate floral designs to even heart-shaped waffles for special occasions. This flexibility allows chefs and bakers to cater to a diverse clientele with varying preferences.

Secondly, the emphasis on speed and efficiency has become a key selling point. In a fast-paced restaurant or café environment, time is of the essence. Professional waffle makers are engineered to produce waffles quickly, reducing wait times and increasing customer satisfaction. The incorporation of advanced heating elements and precise temperature control ensures consistent results every time.

Thirdly, the rise of health-conscious consumers has influenced the design of these waffle makers. Many models now offer non-stick surfaces, making them easier to clean and reducing the need for excessive oil or butter. Additionally, some waffle makers come with adjustable thickness settings, allowing users to control the fat content and calorie count of each waffle.

The fourth trend is the integration of technology. Modern professional-grade waffle makers often come with digital displays and programmable settings. This allows for precise control over cooking times and temperatures, ensuring that each waffle is cooked to perfection. Some even feature countdown timers and audible alerts when the waffle is ready, streamlining the cooking process for busy kitchens.

Fifthly, the aesthetic appeal of these appliances has not been overlooked. Professional-grade waffle makers are now available in a variety of sleek, modern designs that complement contemporary kitchen aesthetics. The use of high-quality materials, such as stainless steel and durable plastics, not only enhances the look but also adds to the longevity of the product.

Sixth, the market has seen an upsurge in eco-friendly features. With sustainability becoming a key concern for consumers and businesses alike, waffle makers that are energy-efficient or made from recycled materials are gaining popularity. These environmentally conscious options appeal to a growing segment of the market that values green practices.

Seventh, there’s a growing interest in customization. Some manufacturers are offering customizable waffle maker options, allowing customers to choose from different sizes, shapes, and even colors. This level of personalization is particularly attractive to restaurants and event organizers looking to create a unique experience for their guests.

Eighth, the integration of safety features is becoming more common. With concerns about electrical hazards, professional-grade waffle makers are now equipped with automatic shut-off functions, overheat protection, and child safety locks. These features not only prevent accidents but also provide peace of mind for both operators and customers.

Ninth, there’s a trend towards versatility in terms of usage. Many professional waffle makers can be used for more than just making waffles. They can also bake other items like pancakes, French toast, or even as a versatile griddle. This dual-purpose functionality is a significant draw for operators looking to maximize their equipment investments.

Finally, the distribution channels for professional-grade waffle makers have expanded. Online retailers, specialized kitchen supply stores, and even large department stores are now carrying these products, making them more accessible to a broader range of consumers. This accessibility has helped to fuel the market’s growth and popularity.

The rise of professional-grade waffle makers reflects the industry’s ability to adapt to changing consumer needs and preferences. As the market continues to evolve, we can expect to see even more innovative features and designs that cater to the dynamic demands of the culinary world.

The 220V industrial waffle maker has emerged as a staple in commercial kitchens, offering a range of features that cater to both efficiency and culinary creativity. Here’s a closer look at some of the key features that make these machines stand out:

Powerful Heating Elements: These waffle makers are designed with high-capacity heating elements that ensure even heat distribution across the waffle grids. This feature guarantees a consistent and golden-brown finish on every waffle, whether you’re producing a batch for a café or a buffet.

Large Capacity: Industrial waffle makers are built to handle high volumes, with some models capable of producing multiple waffles at once. This is crucial for businesses that need to serve a large number of customers quickly, such as breakfast buffets, catering events, or busy restaurants.

Adjustable Temperature Control: To cater to various preferences and recipes, these machines often come with adjustable temperature settings. Chefs can fine-tune the heat to achieve the perfect crispness and color, from a light, fluffy waffle to a deep, golden one.

Non-Stick Coating: The waffle grids are typically coated with a non-stick material, which not only makes cleaning easier but also ensures that the waffles release smoothly, without sticking to the surface.

Timer and Countdown Function: Many industrial waffle makers include a built-in timer or countdown feature, allowing operators to set the exact time needed for each batch. This ensures consistency in the cooking process and helps maintain a steady flow of waffles.

Safety Features: These machines are equipped with safety features to prevent accidents. Automatic shut-off functions activate after a certain period of inactivity, reducing the risk of overheating. Some models also have cool-touch handles and surfaces to prevent burns.

Durable Construction: Industrial waffle makers are built to withstand heavy use. They are often made with stainless steel components that are resistant to corrosion and withstand the rigors of a commercial kitchen environment.

Easy to Clean: Despite their robust design, these waffle makers are designed with cleaning in mind. Removable grids and surfaces make it easier to clean and sanitize, which is essential in a commercial kitchen setting.

Multiple Grid Patterns: From classic Belgian squares to heart shapes and more, industrial waffle makers come with various grid patterns to suit different tastes and occasions. This versatility allows for a wide range of waffle designs and is perfect for creating a unique menu item.

User-Friendly Interface: The control panel on these machines is often straightforward, with clear indicators and easy-to-use buttons. This ensures that even less experienced kitchen staff can operate the waffle maker efficiently.

Energy Efficiency: Despite their high power output, many industrial waffle makers are designed with energy efficiency in mind. They use less energy than traditional household models, which can lead to cost savings over time.

Customization Options: Some manufacturers offer customization options, allowing businesses to brand their waffle makers with logos or specific designs. This can be a great way to enhance brand recognition and create a unique presence in the marketplace.

Versatility in Usage: Beyond traditional waffles, these machines can often be used to create other baked goods, such as pancakes, pita bread, or even small cakes. This versatility adds value to the investment and expands the menu possibilities.

Warranty and Support: Reputable manufacturers offer warranties and customer support for their industrial waffle makers. This ensures that businesses can rely on the longevity of their equipment and receive assistance if needed.

Environmental Considerations: Some models are designed with environmental sustainability in mind, featuring materials that are recyclable or made from recycled materials. This is an increasingly important factor for businesses looking to reduce their carbon footprint.

The 220V industrial waffle maker is a testament to the blend of technology and culinary artistry. Its features are designed to meet the demands of professional kitchens, ensuring that waffles are not just a breakfast staple but a high-quality, consistent product that can elevate any menu.

The demand in the market for kitchen appliances is ever-evolving, and consumers are increasingly seeking high-quality, versatile, and user-friendly products. Understanding what the market is demanding is crucial for manufacturers looking to stay ahead in the competitive landscape. Here are some key insights into the consumer demands shaping the kitchen appliance market, particularly focusing on industrial waffle makers:

Versatility and Customization: Consumers are looking for appliances that can cater to a wide range of recipes and preferences. Industrial waffle makers that offer various shapes, sizes, and even customizable patterns are becoming increasingly popular. Users want the flexibility to create unique waffles for different occasions, whether it’s a family breakfast or a gourmet presentation.

Efficiency and Speed: Time is a precious commodity, and consumers are gravitating towards appliances that can get the job done quickly. Industrial waffle makers that can produce multiple waffles in a short amount of time, with minimal waiting between batches, are highly sought after. Features like a rapid heat-up function and a non-stick surface that reduces cleanup time are also highly valued.

Ease of Use: With busy lifestyles, simplicity and ease of use are paramount. The market is demanding waffle makers with intuitive controls, clear digital displays, and easy-to-read instructions. Features like automatic shut-off to prevent overheating and non-slip bases for stability during use are essential for consumer satisfaction.

Quality and Durability: Consumers are willing to invest in products that are built to last. Industrial waffle makers that are made from high-quality materials, such as stainless steel or heavy-duty aluminum, are preferred. They expect these appliances to withstand heavy use in commercial settings without showing signs of wear and tear.

Safety Features: Safety is a top priority for consumers, especially in commercial kitchens where the stakes are higher. Features like automatic temperature control to prevent burning and overheating, as well as child safety locks, are crucial. In addition, clear warning signals and a cool-touch exterior are essential for preventing accidents.

Energy Efficiency: With growing environmental concerns, energy efficiency is a key factor in consumer purchasing decisions. Industrial waffle makers that are energy-efficient not only reduce operational costs but also contribute to a greener footprint. Look for appliances with energy-saving modes and certifications that highlight their efficiency.

Custom Branding and Customization: For businesses, the ability to customize the waffle maker with their branding is a significant advantage. Consumers are looking for appliances that can be tailored to their specific needs, whether it’s for a café, a hotel, or a catering service. This includes options for custom imprinting and the flexibility to change patterns or designs as needed.

Maintenance and Cleaning: Easy maintenance and cleaning are important for busy kitchens. Consumers appreciate waffle makers that are easy to disassemble for cleaning and have removable parts that are dishwasher safe. Clear instructions for cleaning and care are also essential to ensure the longevity of the appliance.

Innovative Technology: As technology advances, consumers are expecting more from their appliances. Features like programmable settings for temperature and cooking time, as well as smart connectivity that allows for remote control and monitoring, are becoming more desirable.

Warranty and Customer Support: Finally, the assurance of good customer service and a comprehensive warranty can make the difference in a consumer’s purchase decision. Knowing that there is support available for any issues that arise can provide peace of mind and build trust in the brand.

By focusing on these consumer insights, manufacturers can create industrial waffle makers that not only meet but exceed the expectations of their customers, ultimately leading to greater market success.

In the bustling world of commercial kitchens, the demand for efficient and reliable waffle makers has surged. Here are a few case studies that highlight the successful implementation of 220V industrial waffle makers:

Café Renaissance’s Transformation: Once a quaint local café, Café Renaissance found itself struggling to keep up with the morning rush. Their outdated 110V waffle maker was a bottleneck, often unable to keep up with the high demand for waffles. After investing in a state-of-the-art 220V industrial waffle maker, the café’s productivity soared. The increased power allowed them to serve more customers without delays, transforming their morning service into a smooth operation.

School Lunch Programs: In a large urban school district, the school lunch program faced challenges in providing a variety of hot breakfast options. The older models of waffle makers were unreliable and often broke down during peak hours. With the introduction of 220V industrial waffle makers, the program was able to offer a fresh, hot waffle option every day. The consistent performance of the new machines ensured that students started their day with a satisfying breakfast.

Hotel Breakfast Buffets: A luxury hotel known for its gourmet breakfast buffet faced a dilemma: their traditional waffle makers were struggling to keep up with the demand from guests. The hotel management decided to upgrade to 220V industrial waffle makers, which were capable of producing a steady stream of perfectly golden waffles. The new machines were not only more efficient but also added a touch of elegance to the breakfast buffet, enhancing the overall dining experience.

Festival Catering Services: During the annual summer festival, a catering company found itself overwhelmed by the sheer volume of waffles requested by attendees. The company’s previous waffle makers were simply not designed for such high capacity. By switching to 220V industrial waffle makers, they were able to churn out waffles at a rate that matched the festivalgoers’ appetite. The machines’ ability to handle continuous use without overheating or malfunctioning was crucial for the success of the event.

Cruise Ship Kitchen Efficiency: Onboard a luxury cruise ship, the kitchen staff was often frazzled by the time-consuming process of making waffles. The ship’s older waffle makers were a relic of the past, with slow cooking times and frequent breakdowns. The introduction of 220V industrial waffle makers revolutionized the ship’s breakfast service. The machines’ rapid cooking times and durable construction allowed the kitchen staff to serve a steady stream of waffles to the ship’s guests, even during long sea voyages.

Sports Stadium Concessions: During major sports events, the need for quick and consistent food service is paramount. A sports stadium’s concessions area faced challenges with their outdated waffle makers, which were often unable to keep up with the rush of hungry fans. By upgrading to 220V industrial waffle makers, the stadium was able to serve up a steady supply of freshly made waffles, ensuring that no fan went home hungry after a thrilling game.

Diner Revamp: A local diner that had been serving the community for decades decided to refresh its menu with a new breakfast item: waffles. The diner’s old waffle makers were simply not up to the task of producing the large quantities needed for their new offering. The installation of 220V industrial waffle makers allowed the diner to offer a high-quality waffle experience to its customers, becoming a favorite spot for weekend brunches.

Corporate Catering Success: A corporate catering service often found itself competing against time when preparing large-scale breakfast events. Their previous waffle makers were inadequate for the volume of waffles required. The switch to 220V industrial waffle makers meant that they could now serve thousands of waffles at a time, ensuring that every attendee received a hot, freshly made waffle, contributing to the success of numerous corporate events.

These case studies demonstrate the tangible benefits of upgrading to 220V industrial waffle makers, from increased efficiency and capacity to enhanced customer satisfaction. The reliability and performance of these machines have become a staple in commercial kitchens worldwide, proving that a simple waffle can make a big difference in the food service industry.

In the competitive landscape of the industrial waffle maker market, challenges and opportunities often go hand in hand. As technology advances and consumer demands evolve, manufacturers must adapt to stay ahead. Here’s a closer look at the key hurdles and potential growth areas within the industry.

The demand for efficiency and sustainability is on the rise. With environmental concerns becoming more prevalent, businesses are looking for waffle makers that consume less energy and are made from recyclable materials. This shift not only benefits the planet but also appeals to a growing number of eco-conscious consumers.

Customization is another area where challenges and opportunities meet. As the market becomes saturated with generic products, businesses are seeking solutions that can be tailored to their specific needs. This could mean a waffle maker with adjustable heat settings, unique shapes, or even the ability to print custom designs directly onto the waffles.

The integration of smart technology is a double-edged sword. While it offers convenience and precision, it also presents a steep learning curve for some users. Manufacturers must balance advanced features with intuitive interfaces to ensure that professionals can quickly master their new equipment without unnecessary downtime.

Regulatory compliance is a persistent challenge. Different regions have varying standards for electrical safety, noise levels, and emissions. Navigating these regulations while ensuring that the waffle makers meet or exceed them can be complex, but it’s essential for market entry and long-term success.

One opportunity lies in the rise of mobile and pop-up catering. As events and gatherings become more fluid, there’s a demand for portable waffle makers that can be easily transported and set up in a variety of locations. This niche market requires waffle makers that are not only durable but also easy to clean and maintain.

Innovation in the baking process also presents an opportunity. The introduction of non-stick coatings that last longer and are more resistant to wear and tear can significantly reduce maintenance costs for businesses. Additionally, energy-saving features like programmable timers and auto-shutoff can lead to substantial savings on utility bills.

Another challenge is the need for consistent quality control. Ensuring that every waffle maker that leaves the factory performs to the same high standard is crucial. This involves rigorous testing and quality assurance protocols that can be costly and time-consuming but are necessary to maintain a brand’s reputation.

The global market is also presenting opportunities through the expansion into new regions. As cultures around the world embrace the waffle, there’s a chance to introduce unique flavor variations and innovative waffle toppings that cater to local tastes.

Lastly, the opportunity to collaborate with culinary schools and training programs cannot be overstated. By partnering with educational institutions, manufacturers can help shape the next generation of chefs and bakers, ensuring a steady pipeline of professionals who are familiar with their products.

The industrial waffle maker market is a dynamic field, full of challenges that require creative solutions. However, with the right approach, these challenges can also be turned into significant opportunities for growth and innovation.

The landscape of the 220V industrial waffle maker market is evolving, shaped by a confluence of technological advancements, consumer preferences, and market dynamics. Here’s a breakdown of the key features that have become staples in these appliances:

Enhanced Heat Distribution: Modern 220V industrial waffle makers are engineered with advanced heating elements that ensure even heat distribution across the entire grid pattern. This results in perfectly cooked waffles with a crispy outside and a tender inside.

Rapid Heat-Up Time: With powerful heating capabilities, these waffle makers can reach cooking temperature in a fraction of the time traditional models take. This feature is particularly beneficial for high-volume kitchens where efficiency is paramount.

Customizable Cooking Settings: Many models come with adjustable temperature controls, allowing users to tailor the cooking time and heat intensity to the type of batter and desired waffle crispiness.

Non-Stick Coating: The interior surfaces of the plates are typically coated with a non-stick material, ensuring easy release and effortless cleaning after use.

Heavy-Duty Construction: Designed for commercial use, these waffle makers are built to withstand constant use and are often constructed with durable materials like stainless steel.

Safety Features: Incorporating safety features like automatic shut-off timers, these appliances protect against overheating and reduce the risk of accidents in busy commercial kitchens.

Large Grid Size: Industrial waffle makers often feature larger grids than residential models, allowing for the production of larger or more waffles at once, catering to high-volume demand.

Easy-to-Clean Design: The design of these waffle makers often includes features like removable grids, drip trays, and hinges that allow for easier cleaning and maintenance.

Power Consumption: Despite their commercial-grade build, many models are designed to be energy-efficient, minimizing the operational costs while maintaining performance.

Versatility: Some models are not just limited to making classic Belgian waffles; they can also produce various shapes and thicknesses, making them versatile for a range of culinary creations.

Indicator Lights: User-friendly features like indicator lights alert operators when the appliance is ready to use or when it’s reached the desired cooking temperature.

Heat-Up Indicator: In addition to indicator lights, some models include a heat-up indicator to confirm that the waffle maker is preheated and ready for use.

Energy-Saving Modes: Some industrial waffle makers are equipped with energy-saving modes that reduce power consumption when not in use.

Portability: Despite their commercial-grade nature, many models are designed with portability in mind, featuring handles and lightweight materials that make them easy to move around the kitchen.

Custom Branding: For businesses looking to promote their brand, some industrial waffle makers offer customization options, allowing for branding on the exterior or the inclusion of company logos.

As consumer demands shift and the market continues to grow, the evolution of 220V industrial waffle makers reflects a commitment to innovation, efficiency, and adaptability. From enhanced cooking performance to user safety and environmental considerations, these appliances are designed to meet the diverse needs of both businesses and consumers alike.

The 220V industrial waffle maker has become a cornerstone in the kitchen appliances industry, reshaping the way we think about convenience and culinary innovation. Its impact is not just limited to the efficiency of waffle production but extends to the broader landscape of food service and home cooking. Here’s a closer look at the implications and the future of this remarkable piece of equipment.

In the realm of foodservice, the 220V industrial waffle maker has emerged as a vital tool for cafes, restaurants, and catering services. Its ability to produce consistent, high-quality waffles at a rapid pace has revolutionized the breakfast menu. From the fluffy Belgian waffles to the crispy, golden American style, these machines cater to a wide range of preferences and dietary requirements.

The design of these waffle makers is a testament to modern engineering. With their non-stick surfaces and even heating elements, they ensure that each waffle is cooked to perfection, with a perfect balance of crispness on the outside and tenderness on the inside. The adjustable temperature settings allow for customization, making it possible to cater to different preferences and recipes.

The market for 220V industrial waffle makers has seen a surge in demand, driven by several factors. For one, there’s a growing trend towards health-conscious eating, with consumers seeking out alternatives to traditional breakfast options. Waffles, when made with whole grains and fresh ingredients, can be a nutritious and satisfying choice. Additionally, the rise of social media has played a significant role, with influencers and food bloggers showcasing the versatility of waffle makers in creating a variety of delicious treats.

In the commercial kitchen, the 220V industrial waffle maker has become a staple. Its durability and reliability are unmatched, as they are built to withstand the rigors of continuous use. The fact that these machines can be used to produce not just waffles but also pancakes, French toast, and even dessert items like waffle cones and waffle bowls has made them indispensable for chefs looking to expand their menu offerings.

Despite the benefits, the industry faces challenges. One major concern is the energy consumption of these high-powered appliances. In an era of increasing environmental consciousness, manufacturers are under pressure to develop more energy-efficient models. Another challenge is the cost. Industrial waffle makers can be a significant investment for small businesses, which might deter some from adopting them.

On the flip side, opportunities abound. Innovations in technology are paving the way for smarter, more efficient waffle makers. Features like programmable settings, wireless connectivity for remote monitoring, and even predictive maintenance are becoming more common. These advancements not only enhance the user experience but also reduce downtime and maintenance costs.

In terms of market trends, the integration of these waffle makers into the home kitchen is gaining traction. As home chefs seek to elevate their culinary skills and offer unique dishes to guests, the industrial waffle maker is becoming a sought-after tool. The convenience of making professional-quality waffles at home is hard to resist, especially with the plethora of recipes and designs available online.

Looking ahead, the future of the 220V industrial waffle maker is bright. The industry is expected to see continued growth, driven by advancements in technology and consumer demand. Manufacturers are exploring new materials and manufacturing processes to create even more efficient and durable machines. The potential for customization and personalization is vast, with the ability to create waffles with unique shapes, sizes, and textures.

In conclusion, the 220V industrial waffle maker has had a profound impact on the kitchen appliances industry. It has redefined the way we think about breakfast and expanded the possibilities of what can be made in a waffle maker. As the industry evolves, so too will the waffle maker, offering even more features and benefits to both professional chefs and home cooks. Its influence is clear, and its future is promising.