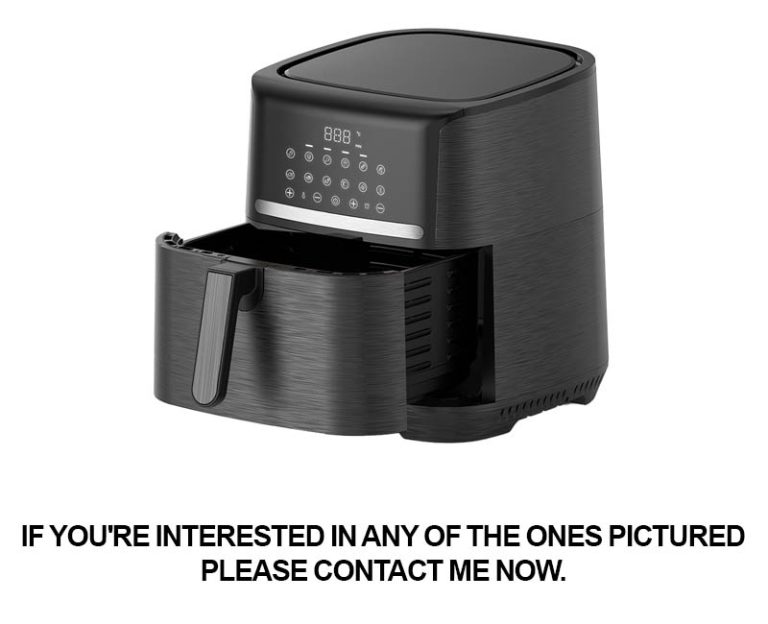

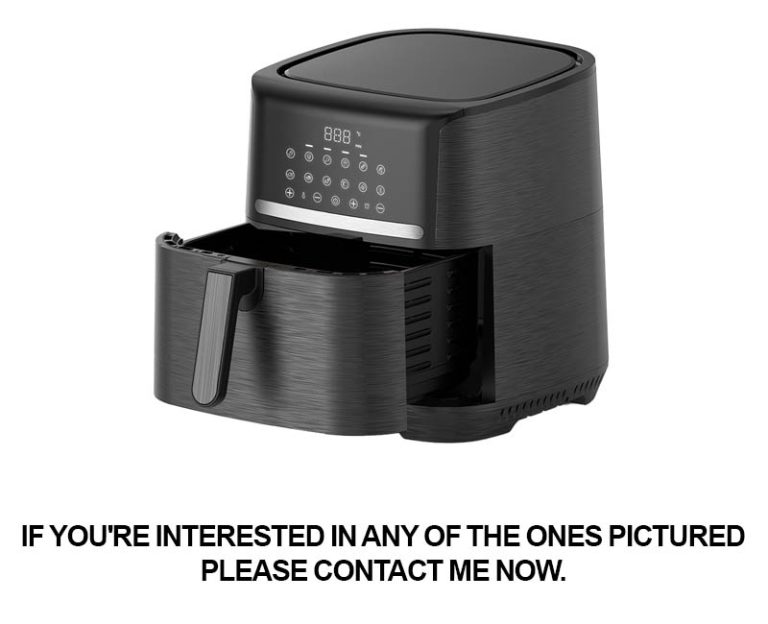

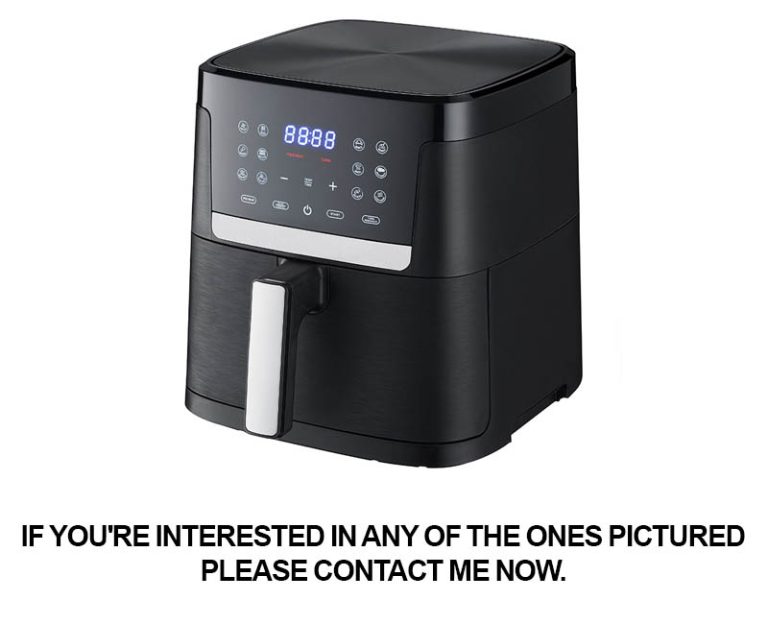

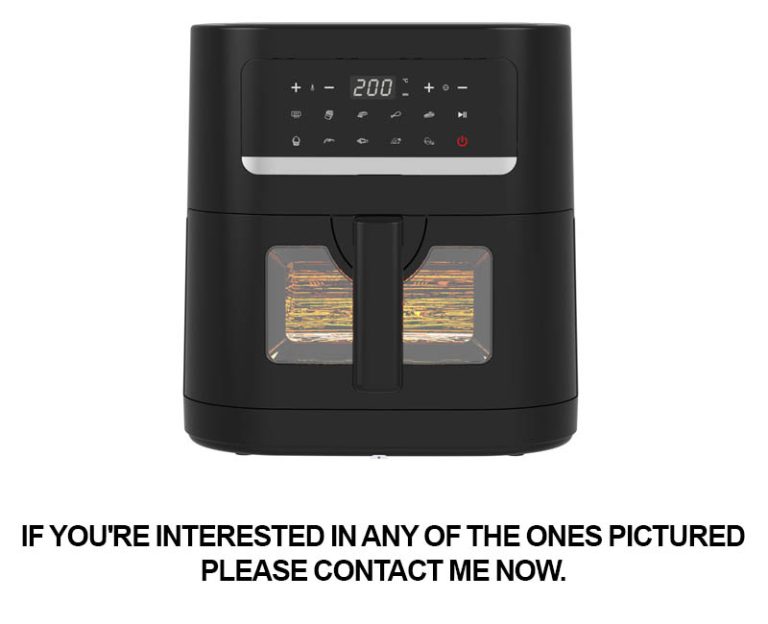

In the rapidly growing appliance market, air fryers have become a staple in modern kitchens, thanks to their ability to offer healthier, oil-reduced cooking. Turnkey solutions, especially those with UL certification, are crucial for success in this sector. These comprehensive OEM partnerships provide a streamlined approach to air fryer development, ensuring safety, quality, and innovation. With a focus on smart technology integration, customization, and eco-friendly designs, turnkey UL certified air fryer OEMs are revolutionizing cooking experiences, meeting the rising demand for efficient and health-conscious appliances.

The NSF Certified 1800W Air Fryer is a game-changer in kitchen appliances, offering a healthier, convenient cooking experience. With its ability to cook delicious, crispy meals using minimal oil, it redefines what an air fryer can do. This powerful appliance, featuring a sleek design and rigorous NSF certification, ensures safety and high-quality performance. Its 1800W motor cooks quickly and evenly, locking in flavors and nutrients without excess fat. Versatile and easy to use, the air fryer is perfect for everything from snacks to main dishes, making it an essential tool for any health-conscious cook.

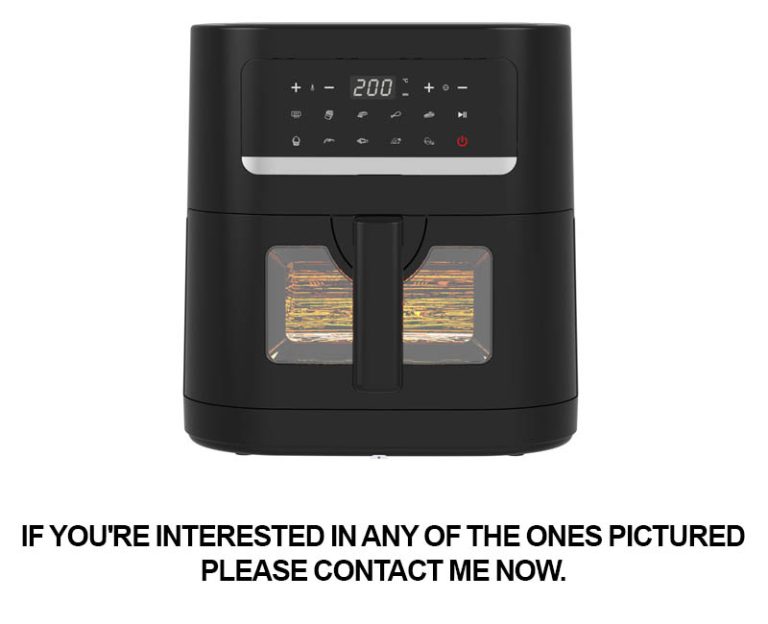

In the evolving culinary landscape, ETL listed commercial units are revolutionizing the commercial kitchen scene. These advanced appliances merge cutting-edge technology with efficiency, offering features like smart connectivity, energy-saving modes, and durable construction. The integration of these features not only streamlines kitchen operations but also enhances safety and sustainability. With a focus on user-friendly design and versatile functionality, ETL listed units are setting new standards in the industry, driving the future of commercial kitchen innovation.

As the air fryer market booms, FOB Ningbo stands out as a premier hub for top-tier air fryer suppliers. Nestled in China’s dynamic coastal region, Ningbo offers a strategic gateway for exporting these versatile cooking appliances. Known for its commitment to quality, the FOB Ningbo air fryer supplier scene boasts innovative designs and cost-effective solutions. These suppliers are not just meeting health-conscious consumer demands by providing low-oil cooking options; they’re also driving industry trends with cutting-edge technology and eco-friendly practices. By choosing a FOB Ningbo air fryer supplier, you gain access to a diverse range of products that cater to both individual home cooks and commercial kitchens, all while enjoying the convenience and efficiency that this modern cooking revolution brings.

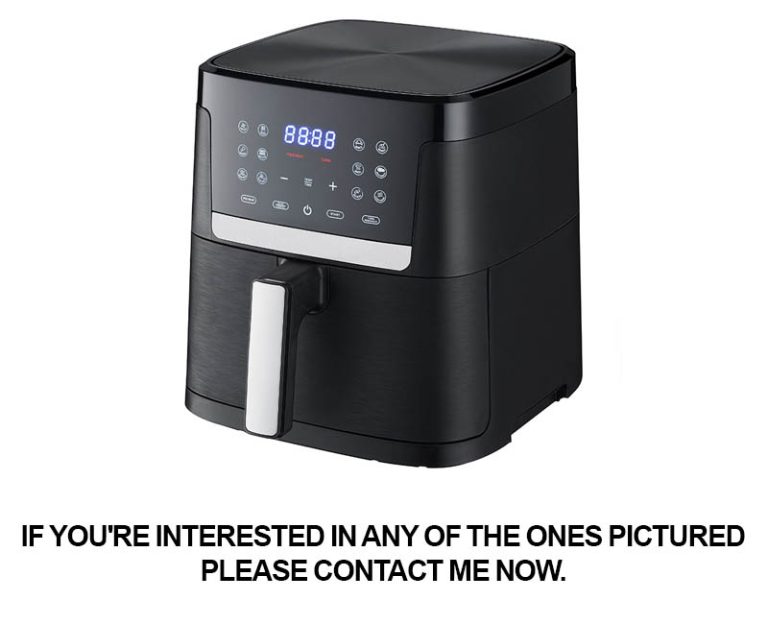

The advent of CE-EMC compliant 2200W kitchen appliances has revolutionized cooking, offering a blend of power and efficiency. These high-powered devices redefine the kitchen experience, providing speed, precision, and convenience. With a surge in demand, they are becoming the new standard, integrating smart technology and adhering to rigorous European and American safety standards. This evolution in kitchen appliances not only enhances cooking performance but also contributes to energy conservation and a safer cooking environment.

The Moscow air fryer manufacturer has emerged as a trailblazer in the kitchen appliance industry, revolutionizing cooking with its innovative air fryers. Known for their sleek designs and health-conscious features, these air fryers offer a healthier alternative to traditional frying methods. With advanced technology that minimizes oil usage and maximizes flavor, the Moscow air fryer manufacturer is not only keeping up with the times but shaping the future of home cooking. Their commitment to quality, sustainability, and cutting-edge technology has made them a favorite among consumers seeking efficient and delicious meal preparation.

The commercial air fryer factory has revolutionized cooking with its innovative appliances. These air fryers not only change the way chefs prepare food but also influence consumer preferences, driven by health and efficiency trends. These compact, efficient devices have become a staple in commercial kitchens globally, leading to a surge in factory establishment and expansion. As these factories invest in research and development, they’re producing air fryers with advanced features like programmable settings, temperature control, and self-cleaning capabilities. This technological evolution ensures a healthier, more efficient, and delicious culinary landscape, with a focus on sustainability and market diversification.

The restaurant-grade air fryer has emerged as a revolutionary appliance in the cooking industry. These innovative devices, crafted in factories with precision and care, have transformed the way we cook by offering a healthier, more efficient alternative to traditional frying methods. By utilizing rapid air circulation and minimal oil, air fryers provide a crispy texture akin to deep-fried foods while significantly reducing calorie and fat content. This not only benefits personal health but also contributes to a greener planet, as they consume less energy and reduce oil waste. As these appliances gain popularity, they are reshaping the culinary landscape, making cooking more enjoyable and sustainable.

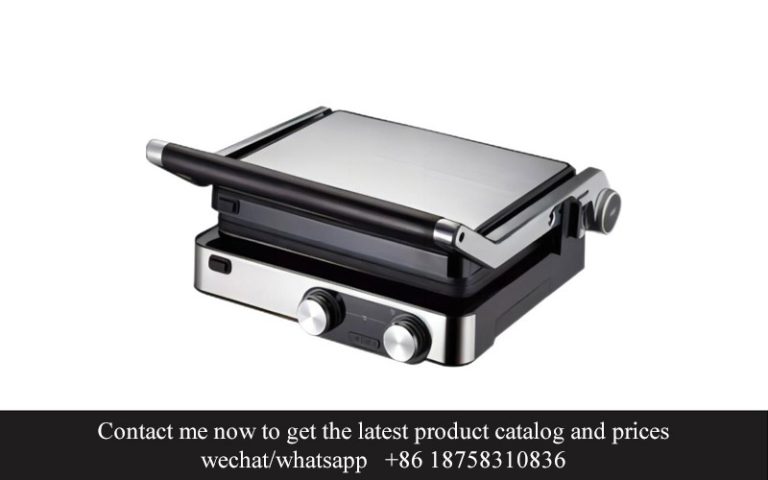

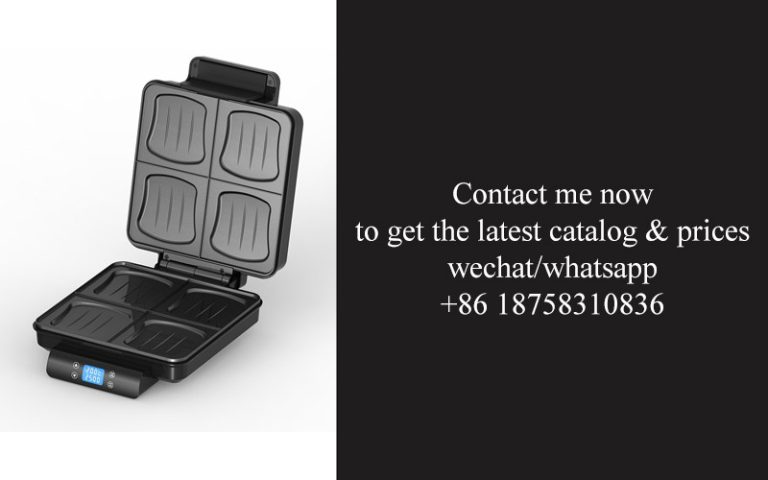

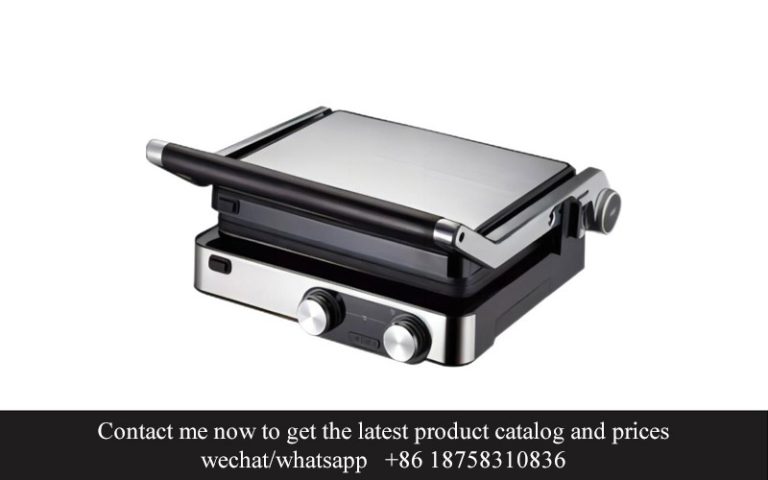

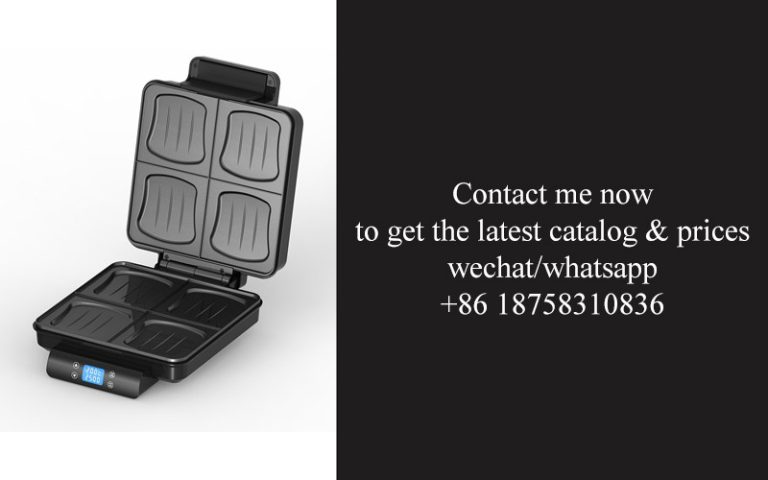

The heavy duty sandwich press factory has revolutionized cooking with its innovative appliance, Sure-Cooking. This versatile kitchen gadget redefines the art of making sandwiches, offering a symphony of flavors and textures with its even heat distribution and non-stick surface. Crafted with robust features and durability, these presses cater to both home cooks and gourmet enthusiasts, transforming a simple sandwich into a mouthwatering masterpiece. The factory’s commitment to quality and innovation ensures that every sandwich press is a reliable companion in the kitchen, perfect for any cooking endeavor.

The continuous operation sandwich grill plant represents a revolutionary advancement in kitchen appliances, significantly enhancing cooking efficiency and productivity. This innovative technology allows for seamless, uninterrupted sandwich preparation, ensuring consistent quality and speed. By streamlining the cooking process, the plant reduces labor costs, optimizes kitchen space, and minimizes energy consumption, making it a game-changer for commercial kitchens worldwide. The continuous operation sandwich grill plant is poised to redefine the future of cooking, offering a robust and efficient solution for foodservice operations.