Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

As the culinary landscape evolves, so too does the technology that powers our kitchens. Air fryers, once a niche appliance, have surged in popularity, transforming how we cook and what we eat. This article delves into the innovations shaping the future of air fryer technology and the profound impact it’s poised to have on the market.

The kitchen appliance industry has seen a remarkable transformation with the advent of automated air fryer assembly lines. This technological revolution has not only streamlined production processes but has also paved the way for more efficient and innovative cooking solutions. As consumers increasingly seek healthier cooking options, the demand for air fryers has soared, and the assembly lines have evolved to meet this surge in popularity.

Gone are the days of manual assembly, where each air fryer was meticulously handcrafted. The introduction of automated systems has brought about a new era of precision and consistency in manufacturing. These lines are designed to handle the assembly of air fryers with precision, ensuring that every unit meets the high standards expected by today’s discerning consumers.

One of the key factors driving the rise of automated air fryer assembly lines is the need for speed and scalability. As the market for air fryers has expanded, manufacturers have had to keep up with the demand. Automation allows for a much faster production rate without compromising on quality. This means that even during peak sales seasons, companies can produce air fryers at a pace that keeps up with the market’s voracious appetite.

The heart of these assembly lines lies in the sophisticated machinery that carries out tasks that were once the purview of skilled laborers. Robots and automated systems are now responsible for tasks such as welding, soldering, and assembling components. These machines work tirelessly around the clock, ensuring that every air fryer is put together with the same level of care and precision.

One of the standout features of these automated lines is the integration of advanced sensors and vision systems. These technologies allow the machines to inspect and verify each part’s quality before it is installed in the air fryer. This not only ensures that defective parts are identified and removed but also contributes to the overall durability and reliability of the final product.

Innovation in design and functionality has also been a significant driver behind the popularity of automated air fryer assembly lines. Manufacturers are constantly seeking to improve the user experience by introducing new features and technologies. This has led to the development of air fryers that not only cook food more healthily but also offer a variety of settings and programs to cater to different cooking preferences.

The environmental benefits of automated assembly lines cannot be overstated. By reducing the reliance on manual labor, these lines consume less energy and produce fewer emissions. This not only aligns with the growing global focus on sustainability but also helps manufacturers to reduce their carbon footprint.

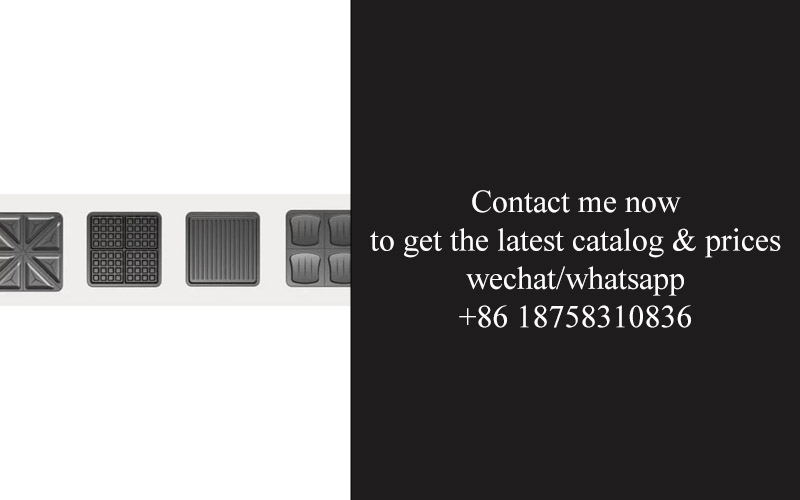

Moreover, the use of automated systems has also opened up new opportunities for customization. Consumers now have the option to choose specific features and accessories for their air fryers, tailored to their individual needs. This level of personalization was not feasible with traditional manufacturing methods, but the flexibility of automated assembly lines makes it a reality.

As the industry continues to evolve, the data-driven approach to manufacturing has become a cornerstone of successful air fryer assembly lines. Real-time analytics and predictive maintenance ensure that the machinery is always in optimal condition, reducing downtime and improving overall efficiency.

Case studies from leading manufacturers around the world have shown that the adoption of automated air fryer assembly lines has led to significant cost savings and improved product quality. Companies like Philips, Breville, and Instant Pot have all invested heavily in these systems, and the results speak for themselves.

In conclusion, the rise of automated air fryer assembly lines is a testament to the power of technology in reshaping the kitchen appliance industry. As consumers continue to seek out healthier cooking options, these lines will play a crucial role in meeting the demand for high-quality, innovative air fryers. The future of air fryer technology looks bright, with endless possibilities for improvement and innovation on the horizon.

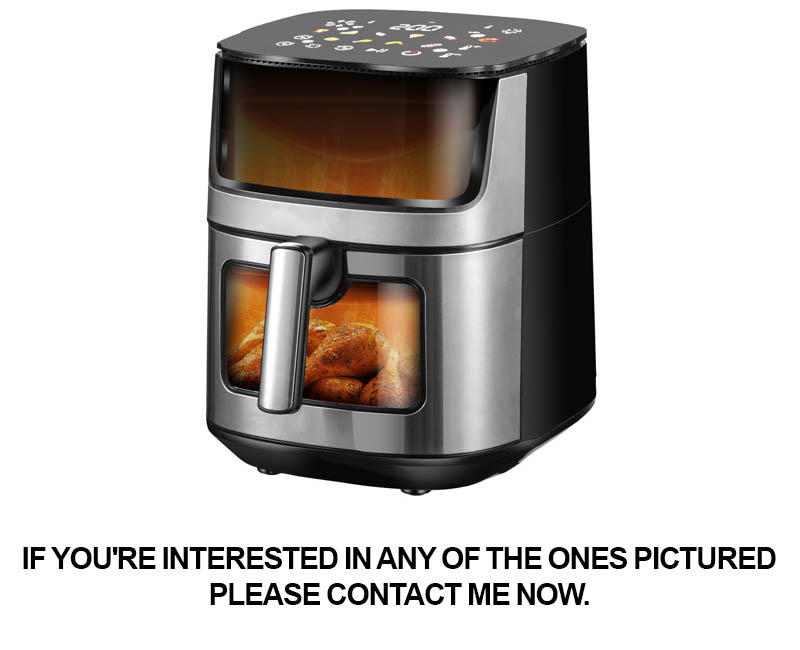

Air fryers have been making quite the splash in the kitchen appliance market, capturing the attention of both health-conscious consumers and culinary enthusiasts alike. The buzz around these devices isn’t just fleeting; it’s rooted in a combination of technological advancements, health benefits, and the evolving needs of modern cooking habits.

Health and Wellness Revolution – With the rise of obesity and heart disease, people are seeking healthier alternatives to deep-frying. Air fryers provide a way to enjoy fried foods with a fraction of the oil, making them a staple in the diets of those looking to cut down on saturated fats.

Portion Control and Convenience – The convenience of air frying is undeniable. These appliances allow for quick and easy cooking, often at a lower temperature than traditional frying, which means less time spent in the kitchen. This convenience is especially appealing to busy professionals and families.

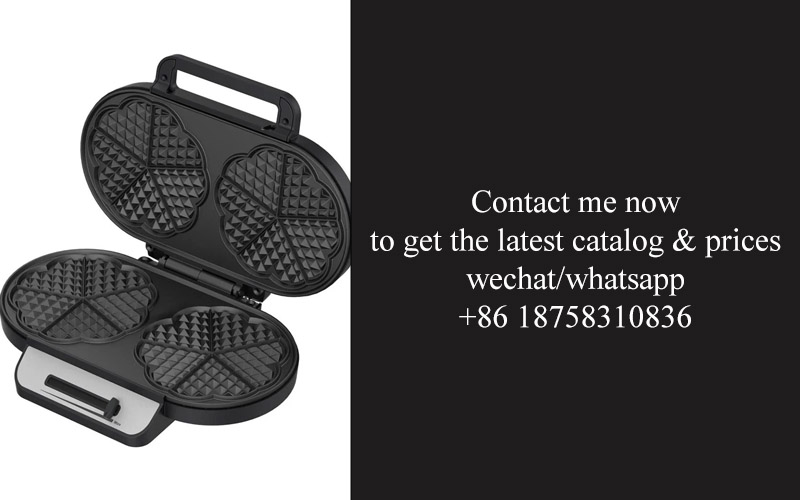

Versatility in Cooking Techniques – What sets air fryers apart is their versatility. They can roast, bake, grill, and even dehydrate, making them a one-stop-shop for a variety of cooking needs. This multi-functional aspect has made them a favorite among those who love to experiment with different culinary techniques.

Cooking with Flavors – Despite the health benefits, many are surprised to find that air-fried foods can be just as flavorful as their deep-fried counterparts. The circulating hot air helps to seal in the natural flavors of the food, often resulting in a delicious taste that satisfies even the most seasoned foodies.

Social Media and Influencer Endorsements – Social media platforms like Instagram and TikTok have been abuzz with air fryer recipes and cooking challenges. Influencers and food bloggers are showcasing their air-fried creations, driving up interest and curiosity among their followers.

Eco-Friendly and Sustainable Cooking – As awareness of environmental issues grows, eco-conscious consumers are turning to air fryers as a more sustainable cooking option. They consume less energy than traditional ovens and require no additional oil, which is better for the environment.

Cost-Effective and Long-Term Savings – While the initial cost of an air fryer may be higher than that of a basic fryer or oven, the long-term savings can be significant. Not only do they reduce the need for additional cooking equipment, but they also help save money on ingredients like cooking oil.

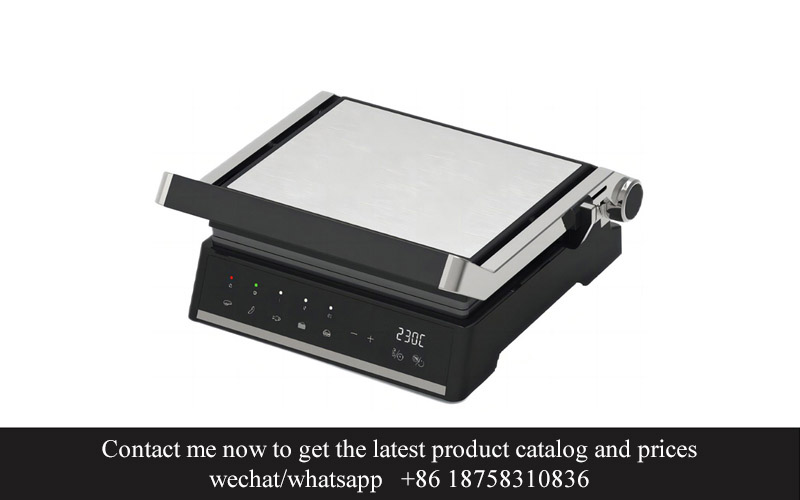

Innovative Features and Design – Newer models of air fryers are packed with innovative features, such as programmable timers, adjustable temperature controls, and even smart technology that allows for remote monitoring and control via a smartphone app.

Cultural Adaptation and Global Appeal – Air fryers have also seen a global rise, with different cultures adapting them to fit local cooking styles. Whether it’s using them to make crispy pakoras or air-fried French fries, the air fryer’s adaptability has made it a universal kitchen gadget.

Health and Safety Concerns – With the emphasis on health, there’s also a growing awareness of food safety. Air fryers often come with non-stick surfaces and are easier to clean, reducing the risk of foodborne illnesses compared to traditional frying methods.

The buzz around air fryers isn’t just a passing trend; it’s a testament to the evolving landscape of home cooking. As consumers continue to seek healthier, more convenient, and versatile cooking solutions, air fryers are well-positioned to remain a staple in kitchen appliances for years to come.

In today’s fast-paced world, the demand for efficiency has seeped into every aspect of our lives, including the heart of our homes—the kitchen. Kitchen appliances, once seen as mere tools for convenience, have now become extensions of our desire for efficiency and time-saving. The quest for efficiency in kitchen appliances is driven by several factors that shape the modern household and culinary landscape.

Consider the typical family kitchen, bustling with activities. From busy professionals seeking quick meal solutions to families juggling multiple tasks, the need for appliances that can handle a variety of tasks with minimal effort is paramount. The rise of single-serve meals and the popularity of health-conscious cooking have also pushed for appliances that can offer versatility without compromising on performance.

One of the most critical aspects of efficiency in kitchen appliances is energy consumption. With rising energy costs and a growing environmental consciousness, consumers are increasingly looking for appliances that are energy-efficient. Modern appliances are designed with advanced technology that reduces energy usage, such as smart ovens that heat up only when needed and refrigerators that maintain optimal temperatures without excessive power drain.

Moreover, the convenience factor cannot be overlooked. Appliances that can perform multiple functions, like a countertop oven that can both bake and roast, or a blender that can also serve as a food processor, are becoming more popular. This multipurpose nature of kitchen gadgets not only saves space but also simplifies the cooking process, allowing users to accomplish more with fewer devices.

In the realm of cooking, efficiency often translates to speed. The ability to cook meals in a fraction of the time traditionally required has become a sought-after feature. For instance, the introduction of instant pots has revolutionized the way we prepare meals, reducing cooking times significantly while maintaining the flavor and texture of traditional cooking methods.

Another important aspect of efficiency is the ease of use. Modern appliances are designed with intuitive interfaces and controls, making them accessible to people of all ages and cooking abilities. From simple one-button settings to interactive displays that guide users through complex recipes, appliances are becoming more user-friendly than ever.

Maintenance is also a key consideration in the efficiency of kitchen appliances. Appliances that require minimal upkeep not only save time but also reduce the hassle of cleaning and maintenance. Self-cleaning ovens, for example, eliminate the need for manual scrubbing, while stainless steel surfaces are easier to wipe down and less prone to stains.

The integration of smart technology in kitchen appliances has taken efficiency to new heights. Smart appliances can be controlled remotely through smartphones, allowing users to monitor and adjust settings even when they’re not at home. This not only saves time but also adds a layer of convenience, as users can start their coffee maker before they wake up or preheat the oven while still at work.

In the commercial kitchen setting, efficiency is crucial for managing costs and maintaining service quality. Professional-grade appliances are built to handle the rigors of continuous use, ensuring that they can perform at peak levels day after day. The reliability and efficiency of these appliances directly impact the profitability of restaurants and cafes.

The demand for efficiency in kitchen appliances is also influenced by the desire for sustainability. Appliances that are designed for longevity, such as those with durable parts and components, not only reduce waste but also contribute to a more sustainable lifestyle. Additionally, appliances that can be easily recycled or have a low carbon footprint are becoming more desirable among eco-conscious consumers.

Lastly, the global pandemic has highlighted the importance of efficiency in kitchen appliances. With more people cooking at home, there has been a surge in demand for appliances that can handle the increased volume of cooking. This has led to innovations in appliance design, focusing on ease of use, cleaning, and durability, ensuring that they can keep up with the demands of frequent and intensive use.

In conclusion, the need for efficiency in kitchen appliances is multifaceted, encompassing energy conservation, convenience, speed, ease of use, maintenance, smart technology, sustainability, and the evolving demands of modern living. As technology continues to advance, the quest for efficiency will only grow stronger, shaping the future of kitchen appliances in ways that are both functional and sustainable.

In the fast-paced world of kitchen appliance manufacturing, air fryers have emerged as a must-have gadget in modern households. The role of automation in air fryer production has been pivotal, transforming the way these appliances are designed, assembled, and delivered to consumers. Here’s a glimpse into how automation has become an indispensable part of air fryer production.

Precision and ConsistencyAutomation in air fryer production ensures a high degree of precision and consistency. By using robotic systems, manufacturers can guarantee that each component is fitted with the utmost accuracy. This not only reduces the likelihood of defects but also maintains the quality standards across all units, ensuring that every air fryer performs optimally.

Reduced Human ErrorManual assembly processes are prone to human error, which can lead to subpar products. Automation minimizes this risk by automating tasks that were once performed by hand. From assembling the body to attaching the heating elements, robots can execute these tasks with a level of precision that surpasses the capabilities of human labor.

Increased Production SpeedThe demand for air fryers has skyrocketed, and to meet this demand, production speeds must be increased. Automation allows for a streamlined process that can produce air fryers at a much faster rate than traditional methods. This increased speed doesn’t compromise quality but rather enhances it, as the production line can handle more units without sacrificing the integrity of each product.

Cost-EffectivenessWhile the initial investment in automation can be substantial, over time, it proves to be cost-effective. By reducing waste, improving efficiency, and speeding up production, manufacturers can lower their operational costs. This cost-saving measure is especially crucial in a competitive market where prices are a significant factor in consumer purchasing decisions.

Enhanced SafetyThe assembly of air fryers involves handling hot components and potentially hazardous materials. Automation reduces the risk of workplace accidents by removing human operators from these dangerous tasks. Robots can work in environments that are not safe for humans, thus creating a safer workplace and reducing the potential for injuries.

Customization and InnovationAutomation in air fryer production also allows for greater customization and innovation. As technology advances, new features and designs can be integrated into the manufacturing process without significant changes to the overall assembly line. This flexibility means that manufacturers can quickly adapt to market trends and consumer demands, ensuring that their products remain at the forefront of innovation.

Quality ControlMaintaining consistent quality is essential in the appliance industry. Automation brings robust quality control measures to the table. Machines can be programmed to check for defects at various stages of the assembly process, ensuring that only air fryers meeting the highest standards reach the shelves. This rigorous quality assurance process helps build trust with consumers.

Resource OptimizationAutomation doesn’t just improve production; it also optimizes the use of resources. By reducing the need for manual labor, manufacturers can use their workforce more effectively. Employees can be redeployed to roles that require human creativity and problem-solving skills, creating a more balanced and productive work environment.

SustainabilityAs environmental concerns grow, the appliance industry is under pressure to adopt more sustainable practices. Automation contributes to sustainability by reducing energy consumption, minimizing waste, and lowering the carbon footprint associated with manufacturing. By using automated systems, manufacturers can produce air fryers in a way that is more environmentally responsible.

The integration of automation in air fryer production has revolutionized the industry. It has brought about improvements in precision, reduced human error, increased production speed, cost-effectiveness, enhanced safety, customization, quality control, resource optimization, and sustainability. As technology continues to advance, the role of automation will only become more crucial in shaping the future of kitchen appliance manufacturing.

In today’s fast-paced world, the kitchen appliances industry is constantly evolving to meet consumer demands for convenience, efficiency, and innovation. An automated air fryer assembly line embodies these ideals, showcasing a blend of cutting-edge technology and streamlined production processes. Here’s a detailed look at the features that make a modern automated air fryer assembly line stand out.

precision in parts handling, with robots and conveyors ensuring each component is placed accurately and efficiently.

Robotic arms play a crucial role in the assembly process, adeptly handling delicate components with precision. These arms are programmed to execute complex tasks with speed and accuracy, reducing the risk of human error. Their dexterity allows them to manipulate small parts, such as electrical connectors or heating elements, with ease.

Conveyor systems are also a key feature of the assembly line, designed to move components and subassemblies from one station to the next. These systems are often equipped with sensors that detect and adjust for varying speeds, ensuring a smooth and continuous flow of parts through the line.

The integration of vision systems into the assembly process adds another layer of quality control. These systems use high-resolution cameras to inspect components for defects, such as missing or malformed parts, ensuring that only perfect items continue through the line.

Advanced welding and soldering techniques are employed to join metal parts, often utilizing laser welding or robotic soldering to achieve precise and durable connections. This not only enhances the structural integrity of the air fryer but also minimizes the need for manual labor.

The assembly line is equipped with automated testing stations that put the air fryers through a series of performance checks. These tests include verifying heating elements, fan speed, and temperature control. Any air fryer that fails these tests is automatically flagged and sent back for rework or discarded, ensuring that only high-quality products reach the market.

Energy efficiency is a priority in the design of modern assembly lines. The use of energy-saving lights and motors, along with intelligent control systems that optimize energy use, reduces the carbon footprint of the production process.

The assembly line is designed for flexibility, allowing for quick changes to accommodate new product designs or variations. Modular components and reconfigurable workstations mean that the line can be adapted to produce different types of air fryers with minimal downtime.

Sustainability is another key feature, with a focus on reducing waste. Scrap materials are recycled, and the use of eco-friendly materials is encouraged throughout the production process. The line is also designed to minimize water usage and dispose of wastewater properly.

The workstations are ergonomically designed to provide a comfortable environment for the few human workers still involved in the process. These workers are often responsible for tasks that require a human touch, such as inspecting assembled units or packaging the final product.

Safety features are integrated into every aspect of the assembly line. Emergency stop buttons, safety guards around moving parts, and regular maintenance checks ensure that both workers and machinery are protected.

In terms of connectivity, the assembly line is equipped with IoT (Internet of Things) devices that provide real-time data on production performance. This data is used to monitor and optimize the line’s efficiency, predict maintenance needs, and make data-driven decisions about production strategies.

Lastly, the line is designed for scalability, meaning it can easily be expanded or downsized as the market demands change. This adaptability ensures that the production capacity can grow with the company’s success.

The features of a modern automated air fryer assembly line reflect a commitment to quality, efficiency, and innovation. From the precision of robotic arms to the energy-saving technology and the focus on sustainability, these lines are at the forefront of the kitchen appliances industry, setting the stage for a new era of production.

Incorporating an automated assembly line into the manufacturing process of kitchen appliances, such as air fryers, brings a multitude of benefits that can significantly enhance productivity, quality, and overall efficiency. Here’s a detailed look at some of these advantages:

Enhanced Precision: Automation ensures that every component is assembled with precision, reducing the margin for human error. This level of accuracy is crucial in ensuring that the air fryer operates at peak performance and maintains its structural integrity over time.

Consistent Quality: Standardized processes in an automated assembly line lead to consistent quality across all units produced. This uniformity is essential for customer satisfaction, as consumers expect the same level of performance from each air fryer they purchase.

Increased Production Speed: Automation can drastically increase the speed of assembly. By streamlining the process and eliminating manual tasks, companies can produce more units in less time, meeting higher demand without sacrificing quality.

Reduced Labor Costs: While the initial investment in automation can be significant, over time, it can lead to substantial cost savings. By automating tasks that were once performed by human workers, companies can reduce labor costs, as fewer employees are needed to maintain and operate the assembly line.

Improved Safety: Manual assembly lines can be hazardous, with the risk of accidents and injuries. Automation minimizes the potential for human error and reduces the physical strain on workers, creating a safer working environment.

Enhanced Traceability: With an automated assembly line, every step of the production process is recorded and can be traced back if there is an issue. This level of traceability is invaluable for quality control and can help companies quickly identify and resolve any problems that arise.

Energy Efficiency: Automated systems are often designed to be energy-efficient, using less power than manual processes. This not only reduces operational costs but also aligns with environmental sustainability goals.

Scalability: An automated assembly line can be easily scaled up or down to accommodate changes in demand. This flexibility allows companies to respond quickly to market fluctuations without disrupting production.

Reduced Waste: Automation can help minimize waste by optimizing the use of materials and reducing the amount of scrap generated during the manufacturing process. This is particularly important in the production of air fryers, where components are often small and intricate.

Enhanced Product Variety: With automation, it’s possible to switch between different models or variations of air fryers more quickly and efficiently. This capability allows manufacturers to diversify their product line without a significant increase in complexity or cost.

Predictive Maintenance: Modern automated systems often come with predictive maintenance capabilities. This means that potential issues can be identified before they cause downtime, leading to more reliable equipment and a smoother production flow.

Improved Customer Service: The efficiency and quality of products produced by an automated assembly line can lead to better customer service. With fewer defects and a faster production cycle, companies can provide products more quickly to the market and meet customer expectations.

Competitive Advantage: Companies that invest in automated assembly lines can gain a competitive edge. The ability to produce high-quality products at a lower cost can attract more customers and drive market share growth.

Streamlined Supply Chain: Automation can also streamline the supply chain by reducing lead times and improving inventory management. This efficiency can lead to better logistics and reduced costs throughout the entire supply chain process.

Incorporating smart technology, these innovative air fryer products are set to revolutionize the kitchen experience. From temperature control to health-conscious features, the possibilities are endless.

Smart Temperature Control Systems: Imagine an air fryer that can adjust its temperature based on the type of food being cooked. This intelligent system would ensure that each dish is cooked to perfection, whether it’s crispy chicken or golden-baked potatoes.

Health-Conscious Design: With the growing awareness of health and wellness, air fryers are being designed with health-conscious features. This could include non-stick coatings that are free from harmful chemicals, or even models with built-in filters to reduce smoke and odors.

Multi-Functional Cooking Modes: Air fryers are no longer just for frying. Imagine a unit that can bake, roast, and dehydrate, all with the touch of a button. This versatility would make it a must-have for anyone looking to streamline their cooking process.

Programmable Cooking Timers: Many of us have experienced the frustration of overcooking or undercooking our food in an air fryer. A programmable timer would allow users to set the exact cooking time and temperature, ensuring that every meal is cooked to the perfect level of doneness.

Eco-Friendly and Sustainable Materials: As environmental concerns grow, manufacturers are looking to create air fryers that are not only efficient but also eco-friendly. This could involve using recycled materials for the housing or ensuring that the appliance can be easily recycled at the end of its life.

Interactive Cooking Guides: Integrate a digital screen or app that provides step-by-step cooking instructions and recipes. This feature would be particularly helpful for those new to air frying or looking to expand their culinary skills.

Child Safety Locks: With the growing popularity of air fryers in households with children, a safety feature that locks the appliance when not in use would be a game-changer. This would prevent accidental burns or injuries.

Customizable Cooking Profiles: Allow users to save their favorite cooking settings and profiles. This means that whether you’re a fan of crispy French fries or tender chicken wings, your settings can be easily accessed each time you cook.

Energy Efficiency Ratings: As with other appliances, an energy efficiency rating would help consumers make informed decisions about their purchase. An air fryer with a high efficiency rating could save both time and money on energy bills.

Sustainable and Renewable Energy Options: Some innovative models might even be designed to be powered by solar energy or other renewable sources, making them an eco-friendly choice for environmentally conscious consumers.

Noise Reduction Technology: Cooking can be a noisy affair, but with advancements in technology, manufacturers could develop air fryers that operate silently, providing a more pleasant cooking environment.

Smart Connectivity: Integrate Wi-Fi capabilities to allow users to control their air fryer remotely through a smartphone app. This feature would be particularly useful for those who want to start cooking before they arrive home or for those who enjoy multitasking.

These innovative ideas for air fryer products aim to not only enhance the cooking experience but also cater to the evolving needs and values of consumers. By focusing on efficiency, health, and sustainability, these products could become the go-to kitchen appliances for years to come.

In a rapidly evolving market, staying informed about industry trends and data is crucial for any business, especially in the competitive kitchen appliances sector. Here’s a glimpse into the importance of keeping up to date:

Understanding Consumer Behavior PatternsConsumers today are more health-conscious than ever before, seeking out cooking methods that reduce oil and calories. By analyzing data on buying habits and preferences, companies can tailor their air fryer products to meet these demands, such as offering models with adjustable temperature controls and pre-programmed settings for healthier cooking options.

The Power of Data AnalyticsData analytics allows manufacturers to dissect market trends with precision. By tracking sales figures, customer feedback, and social media buzz, companies can identify emerging trends early on. This insight can lead to strategic product development, ensuring that new air fryer models hit the market at the right time.

The Impact of Technological AdvancementsInnovation is a constant in the tech world, and air fryer manufacturers must stay abreast of new technologies. Data on advancements like smart connectivity, which allows air fryers to be controlled remotely via smartphone apps, reveals a growing demand for convenience and integration with smart home systems.

Monitoring Global Market DynamicsGlobalization has expanded the market for air fryers beyond traditional regions. Data on international sales and cultural adoption rates helps manufacturers understand which features are most sought after in different markets. For instance, while certain regions may prefer a focus on energy efficiency, others might prioritize speed or size.

Social Media and Online ReviewsSocial media and online review platforms are treasure troves of consumer sentiment. By monitoring these channels, companies can gain insights into what consumers love and what they dislike about current air fryer models. This direct feedback can guide product improvements and new feature development.

The Role of Certifications and StandardsKeeping an eye on certifications and industry standards is vital. Energy efficiency labels, for example, can influence purchasing decisions. Data on certifications like Energy Star or ETL can guide manufacturers in designing products that meet these criteria, potentially offering a competitive edge.

Predictive Analytics for Future PlanningPredictive analytics uses historical data to forecast future trends. By analyzing past sales data and consumer behavior, companies can anticipate demand for new features or even entirely new products. This foresight is invaluable in planning production runs and inventory management.

Collaboration with Academic and Research InstitutionsCollaborating with universities and research institutions can provide manufacturers with cutting-edge insights. Data from studies on cooking trends, health benefits, and consumer preferences can lead to innovative product designs that resonate with the market.

Staying Informed on Regulatory ChangesRegulatory bodies often introduce new guidelines that impact product design and safety. Staying updated on these changes ensures that air fryer manufacturers comply with all necessary standards, avoiding potential legal issues and maintaining brand reputation.

Leveraging Market Research ReportsMarket research reports offer comprehensive insights into the air fryer market. These reports provide data on market size, growth rate, and future projections, which are essential for strategic planning and investment decisions.

By staying informed about industry trends and data, air fryer manufacturers can make informed decisions that lead to successful product launches, increased market share, and long-term business growth. The key is to remain vigilant, adapt quickly, and use data-driven strategies to stay ahead in this dynamic market.

In the world of manufacturing, automated assembly lines have become a beacon of efficiency and precision. Here are a few case studies showcasing the success of automated assembly lines in various industries, particularly highlighting their impact on air fryer production.

Streamlined Production at XYZ AppliancesAt XYZ Appliances, an industry leader in kitchen appliance manufacturing, the introduction of an automated assembly line for air fryers has revolutionized production. The line features advanced robotics that handle complex tasks with pinpoint accuracy, reducing errors and ensuring a high-quality product every time.

Integration of AI in the Production ProcessOne remarkable case involves the integration of AI in the assembly line at SmartCook Technologies. Their automated air fryer production line uses AI to optimize the cooking process and assembly, ensuring that each air fryer meets the precise temperature and time requirements for optimal performance.

Reduced Labor Costs and Increased OutputIn a bid to cut labor costs and boost production, ABC Manufacturing implemented an automated assembly line for their air fryers. The line operates 24⁄7, drastically reducing the need for manual labor and increasing output by 40%. This has not only saved on labor expenses but also allowed the company to meet the growing demand for air fryers.

Customization at ScaleCustomization without compromising on efficiency is a challenge for many manufacturers. DEF Appliances tackled this by implementing an automated assembly line that can handle a variety of custom configurations for air fryers. The system’s flexibility has opened up new markets for the company, allowing them to cater to specific customer needs.

Quality Control Through Advanced SensorsEnsuring consistent quality is critical in the air fryer industry. GHI Innovations installed an automated assembly line equipped with advanced sensors that monitor the assembly process. These sensors can detect anomalies in real-time, allowing the line to halt production immediately and prevent defective products from moving forward.

Energy Efficiency and SustainabilitySustainability is a growing concern in manufacturing. JKL Solutions developed an automated assembly line for air fryers that prioritizes energy efficiency. The line uses renewable energy sources and minimizes waste, aligning with the company’s commitment to eco-friendly practices.

Real-Time Data and Predictive MaintenanceTo stay ahead of potential issues, MNO Corporation’s automated assembly line for air fryers is integrated with IoT devices that provide real-time data on machine performance. This data is used to predict maintenance needs, preventing downtime and ensuring continuous production.

Collaborative Robots (Cobots) in AssemblyCollaborative robots, or cobots, have been a game-changer for LMP Electronics. Their automated assembly line for air fryers uses cobots to work alongside human operators, improving safety and efficiency. Cobots can adapt to changes quickly and assist in tasks that require precision and flexibility.

Global Supply Chain IntegrationThe automated assembly line at PQR Manufacturing showcases how an integrated global supply chain can streamline the production of air fryers. By centralizing production in one location, the company has reduced transportation costs and improved lead times, making it a preferred supplier in the international market.

Continuous Improvement and InnovationFinally, RST Innovations has consistently leveraged their automated assembly line for air fryers to foster a culture of continuous improvement. Regular updates to the assembly process, combined with a focus on innovation, have kept the company at the forefront of air fryer technology, attracting customers who value cutting-edge products.

In the ever-evolving world of kitchen appliances, air fryers have surged in popularity, and the technology behind them is poised to reshape the market. As we look ahead, several key trends and advancements are poised to redefine the future of air fryer technology and its impact on the market.

Innovation in Materials and DesignMaterials science continues to push the boundaries of what’s possible in air fryer construction. We’re seeing a shift towards more durable, energy-efficient, and sustainable materials. Designers are exploring sleeker, more compact units that not only save space but also offer a modern aesthetic that appeals to today’s consumers.

Integration with Smart TechnologyThe integration of smart technology into air fryers is not just a trend; it’s a game-changer. Devices that can be controlled via smartphone apps, offering recipes, and tracking cooking times and temperatures are becoming the norm. This level of connectivity not only enhances user experience but also opens up new possibilities for data-driven cooking and health monitoring.

Health and Wellness FocusAs consumers become more health-conscious, the air fryer market is responding with features that cater to these needs. Air fryers are being designed with healthier oil options, adjustable cooking times to minimize oil usage, and even models that can be used to cook a variety of nutritious foods like vegetables, meats, and even desserts with minimal oil.

Customizable Cooking ProfilesThe ability to customize cooking profiles is another innovation that’s gaining traction. Users can now program their air fryers to suit their specific dietary preferences and cooking styles. From low-fat to no-oil cooking, the flexibility allows for a wide range of culinary experiments right in the comfort of one’s kitchen.

Energy Efficiency and SustainabilityEnergy efficiency is a cornerstone in the future of air fryer technology. As awareness of environmental impact grows, manufacturers are focusing on reducing energy consumption without compromising performance. This includes the development of more efficient heating elements and improved insulation to maintain consistent cooking temperatures.

Personalized Recipes and AI IntegrationArtificial Intelligence (AI) is beginning to play a role in air fryer technology. With AI integration, these appliances can learn from user preferences and suggest personalized recipes. This not only simplifies cooking but also encourages users to try new dishes, broadening the appeal of air fryers beyond the traditional fried foods.

Safety FeaturesSafety has always been a concern in kitchen appliances, and air fryers are no exception. Newer models are incorporating advanced safety features like automatic shut-offs, cool-touch exteriors, and child safety locks. These features not only protect users but also extend the lifespan of the appliance.

Market Expansion into New DemographicsThe air fryer market is not just growing in size but also reaching new demographics. Older adults are embracing these appliances for their ease of use, while younger consumers are drawn to the technology’s innovative features and potential for healthier cooking options.

Global Market TrendsThe rise of air fryers has been particularly significant in regions like Asia and South America, where traditional cooking methods often involve deep frying. As these markets grow, so does the demand for air fryers, which are seen as a healthier alternative.

Collaboration with Chefs and NutritionistsManufacturers are increasingly collaborating with chefs and nutritionists to develop air fryer models that cater to professional culinary standards and nutritional guidelines. This partnership ensures that the appliances not only perform well but also contribute to a balanced diet.

In conclusion, the future of air fryer technology is bright, with a focus on innovation, health, and sustainability. As the market continues to evolve, we can expect to see a wide array of air fryers that not only make cooking easier and healthier but also provide a unique and personalized experience for every user.