Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In a world where culinary trends are ever-evolving, one kitchen gadget has quietly risen to prominence—the heavy-duty sandwich press. This unassuming appliance has not only transformed the art of making sandwiches but has also left its mark on the market. Let’s delve into the world of heavy-duty sandwich presses, exploring the innovative designs, technological advancements, and consumer insights that have propelled this kitchen staple to new heights.

The Heavy Duty Sandwich Press has quietly but surely emerged as a game-changer in the realm of kitchen appliances. Once a niche device, it has now become a staple in many modern kitchens, and for good reason. This robust appliance offers a perfect blend of convenience, versatility, and style, redefining the way we think about homemade sandwiches.

Once confined to the realms of food trucks and gourmet kitchens, the heavy duty sandwich press has now made its way into the hearts of home cooks everywhere. It’s a testament to the ever-evolving culinary landscape, where innovation meets practicality. These presses are not just for toasting your bread; they’re a culinary tool that can transform a simple sandwich into a mouthwatering masterpiece.

The allure of the heavy duty sandwich press lies in its ability to deliver a perfectly toasted crust and a juicy, evenly cooked filling. The even distribution of heat ensures that every bite is a symphony of flavors and textures. Whether you’re a fan of classic grilled cheese, an aficionado of gourmet burgers, or simply someone who loves a good BLT, this appliance has got you covered.

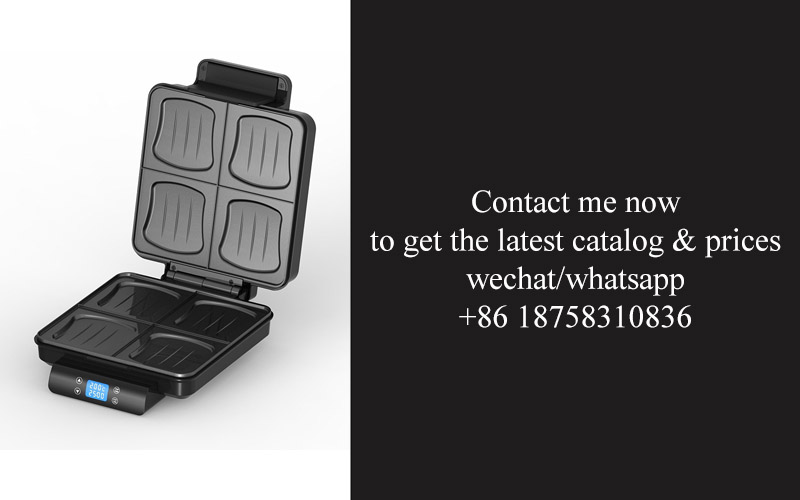

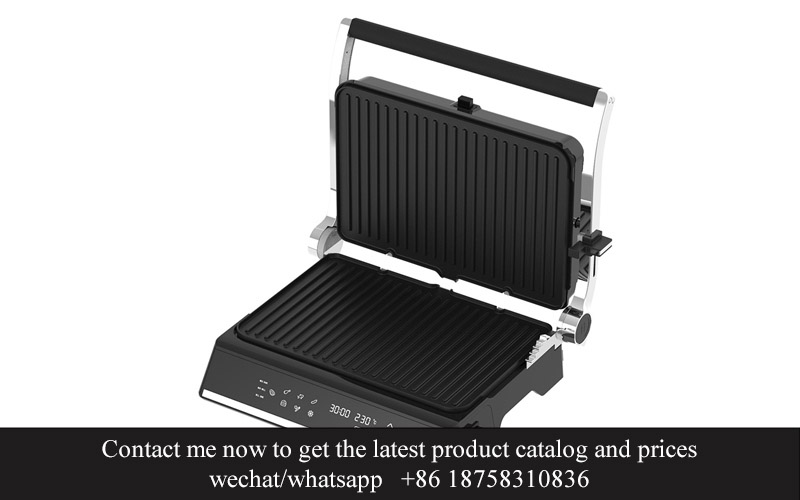

In recent years, we’ve seen a surge in the variety of heavy duty sandwich presses available on the market. From the classic clamshell design to sleek countertop models with digital controls, there’s something for everyone. The rise of these presses can be attributed to several factors, including the growing trend of home cooking and the increasing demand for high-quality, easy-to-use kitchen gadgets.

One of the standout features of a heavy duty sandwich press is its sturdy construction. Made from durable materials like stainless steel and cast aluminum, these presses are built to last. They can withstand the heat and pressure of repeated use, ensuring that they remain a reliable companion in your kitchen for years to come.

Another reason for the heavy duty sandwich press’s popularity is its versatility. While they are best known for their ability to toast bread and sandwiches, many models come with additional features that allow you to cook a variety of dishes. Some presses have adjustable heat settings, allowing you to customize the level of doneness for your food. Others come with non-stick surfaces, making it easier to clean and ensuring that your food won’t stick to the press.

The convenience factor cannot be overlooked. Imagine being able to prepare a gourmet sandwich without the hassle of flipping it over or worrying about uneven cooking. The heavy duty sandwich press does all the work for you, leaving you free to enjoy the process of creating a delicious meal. It’s a simple appliance that can make a big difference in your daily cooking routine.

Moreover, the aesthetic appeal of these presses is undeniable. Modern designs range from minimalist and sleek to bold and colorful, making them a stylish addition to any kitchen. They can complement your existing kitchen decor or even serve as a conversation starter when guests drop by.

In the realm of gourmet cooking, the heavy duty sandwich press has also become a favorite among chefs and culinary enthusiasts. It’s not uncommon to find these presses in high-end restaurants, where they’re used to create unique and visually appealing dishes. The precision and consistency that these presses offer are highly valued in the culinary world.

As the heavy duty sandwich press continues to gain popularity, we’re seeing more and more innovations in the market. Some presses now come with built-in toasting functions, while others offer adjustable pressure settings for different types of sandwiches. The possibilities are endless, and it’s exciting to see what new features will be introduced in the future.

In conclusion, the rise of the heavy duty sandwich press is a testament to the power of innovation and the ever-changing landscape of home cooking. This simple yet powerful kitchen gadget has found its way into the hearts and kitchens of people around the world, and it’s here to stay. Whether you’re a casual cook or a gourmet enthusiast, the heavy duty sandwich press is an essential tool that can elevate your culinary game and bring joy to your kitchen adventures.

In the heart of the bustling appliance manufacturing scene, there exists a factory that stands out as a beacon of innovation—home to the heavy duty sandwich press. This establishment is not just a place where metal and heat come together to forge culinary creations; it’s a hub where ideas are born, refined, and transformed into game-changing kitchen appliances.

The factory’s layout is a testament to efficiency and precision, with each area dedicated to a specific stage of the manufacturing process. The raw materials, ranging from high-grade stainless steel to advanced heating elements, are meticulously handled to ensure that only the finest components are used. Workers move with purpose, their focus on creating a product that will stand the test of time in any kitchen.

At the heart of the factory is the R&D department, a team of culinary enthusiasts and mechanical geniuses. They brainstorm and test new designs, pushing the boundaries of what a sandwich press can do. This division is where the heavy duty sandwich press concept was hatched, combining the ease of a home appliance with the robustness of a commercial-grade tool.

The production line is a marvel of modern engineering. Workers here are skilled artisans, each with a specific role in the assembly process. They expertly weld and rivet the metal components, ensuring that the sandwich press is not just sturdy but also safe for daily use. The heating elements are placed with precision, and the control panels are designed with the user in mind, making the machine both powerful and accessible.

The quality control process is rigorous. Each sandwich press that rolls off the line is subjected to a series of tests. It must withstand intense pressure and maintain even heating throughout its lifespan. This dedication to quality is what sets the factory apart from its competitors, ensuring that every customer receives a product that is reliable and long-lasting.

The factory’s commitment to innovation extends beyond the production floor. They are always looking for new materials and technologies that can enhance the sandwich press’s performance. From exploring the use of thermic fluids for better heat distribution to integrating smart technology for precise temperature control, the possibilities are endless.

Innovation isn’t just about creating new products; it’s also about understanding customer needs. The factory regularly gathers feedback from chefs, home cooks, and even sandwich artists, using this information to improve existing models and develop new ones. This customer-centric approach has helped the factory stay ahead of the curve, catering to a market that is constantly evolving.

The factory’s sustainability initiatives are also noteworthy. They prioritize the use of recycled materials and energy-efficient processes, aiming to minimize their environmental footprint. This eco-friendly stance resonates with consumers who are increasingly conscious of the products they choose to purchase.

As the heavy duty sandwich press factory continues to grow, so does its global presence. Distributors and retailers from all corners of the world seek out their products, drawn by the reputation for quality and innovation. The factory has even ventured into custom manufacturing, creating bespoke sandwich presses for specific industries, such as catering and fast-food chains.

In a world where convenience and quality go hand in hand, the heavy duty sandwich press factory is at the forefront. It’s a place where passion meets precision, and where the dream of a perfect sandwich is turned into reality. With each new model that emerges from this hub of innovation, the factory not only contributes to the culinary landscape but also paves the way for what’s next in kitchen appliances.

A high-quality heavy duty sandwich press is not just a kitchen gadget; it’s a piece of engineering designed to elevate the art of sandwich-making. Here are some of the key features that set these presses apart:

The robust build of a heavy duty sandwich press is its cornerstone. Crafted from durable materials like stainless steel, these presses are built to withstand the rigors of frequent use. Their sturdy construction ensures that they won’t bend or warp over time, maintaining their shape and integrity.

One of the standout features of a top-tier heavy duty sandwich press is its even heat distribution. With precision thermostats and high-quality heating elements, these presses ensure that every square inch of your sandwich is cooked to perfection. No cold spots, no overcooked edges—just a perfectly toasted sandwich every time.

The size of the sandwich press is a crucial factor. A high-quality model offers a generous cooking surface that can accommodate a variety of sandwich sizes, from single servings to hearty double-deckers. This versatility is perfect for families, individuals, or anyone who loves to experiment with different sandwich combinations.

A non-stick surface is a game-changer for sandwich presses. It means less mess, easier cleanup, and the ability to cook a wider range of ingredients without worrying about them sticking to the press. The non-stick coating is also designed to be durable, so it can withstand the heat and pressure of cooking without wearing down.

The handle and lid design are often overlooked but are essential for a user-friendly experience. A high-quality heavy duty sandwich press will have a comfortable, heat-resistant handle that allows for easy opening and closing. The lid should seal tightly to ensure that the heat is contained and the sandwich is cooked evenly.

Safety features are a must in any kitchen appliance, and a heavy duty sandwich press is no exception. Look for models with cool-touch handles and lids, as well as automatic shut-off functions that activate when the press is left unattended for too long. These features not only protect you from burns but also prevent potential fires.

The ability to adjust the cooking temperature is a feature that can make a big difference. A high-quality sandwich press will typically offer a range of temperature settings, allowing you to customize the level of doneness for your bread and fillings. Whether you prefer a lightly toasted sandwich or a crispy, golden-brown exterior, you can achieve it with precision.

A durable and reliable locking mechanism is another hallmark of a high-quality heavy duty sandwich press. It ensures that the press stays closed during cooking, maintaining the pressure and heat needed for even cooking. The mechanism should be easy to use and secure, so you can focus on making your sandwich without worrying about it opening prematurely.

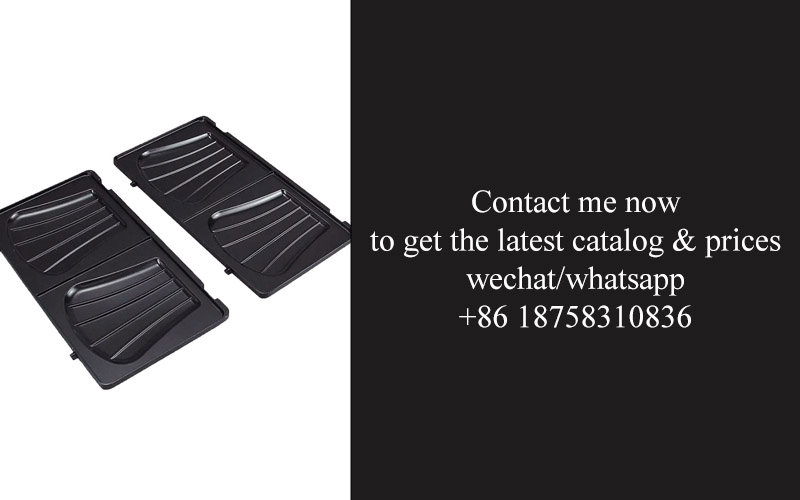

The design of the cooking plates is also important. A high-quality sandwich press will have plates that are flat and even, which helps to prevent the bread from becoming misshapen or unevenly toasted. Some models even come with unique patterns or textures on the plates, which can add a distinctive look to your sandwiches and enhance the grip of the fillings.

Lastly, the brand and warranty can speak volumes about the quality of a heavy duty sandwich press. Look for brands with a reputation for excellence in kitchen appliances, and check the warranty to ensure that you’re investing in a product that’s backed by the manufacturer’s confidence in its durability and performance.

In summary, a high-quality heavy duty sandwich press is defined by its robust build, even heat distribution, size versatility, non-stick surface, user-friendly design, safety features, adjustable temperature settings, durable locking mechanism, well-designed plates, and the backing of a reputable brand with a solid warranty. These features come together to create an appliance that not only makes great sandwiches but also stands the test of time in your kitchen.

The heavy-duty sandwich press factory has become a pivotal player in the kitchen appliance market, leaving a lasting impact with its high-quality products. From driving innovation to meeting consumer demands, here’s how this factory is reshaping the industry:

In the heart of the manufacturing facility, precision engineering meets culinary craftsmanship, resulting in sandwich presses that are not just tools but works of art. These heavy-duty presses are built to withstand the rigors of commercial use, making them ideal for busy cafes, restaurants, and delis.

The factory’s commitment to quality is evident in the materials used, with sturdy construction and durable components ensuring that each press is a long-term investment. The use of high-grade metals and heat-resistant materials means these presses can handle the intense pressure required to perfectly sear the bread and toppings of a gourmet sandwich.

One of the most significant impacts of the heavy-duty sandwich press factory is the rise in the popularity of custom-designed sandwich presses. Businesses can now order presses that match their branding, creating a cohesive look for their establishments. This level of personalization is a testament to the factory’s ability to cater to the unique needs of its clients.

The factory’s focus on innovation has led to the development of sandwich presses with advanced features. These include adjustable heat settings for perfecting different types of sandwiches, non-stick surfaces for easy cleaning, and ergonomic handles for comfortable use. These features not only enhance the user experience but also streamline the cooking process, saving time and effort in high-volume settings.

Safety is a top priority in the design of these heavy-duty sandwich presses. With built-in heat controls and automatic shut-off features, the factory ensures that operators can work safely without the risk of burns or fires. This attention to safety has made the presses a preferred choice for health-conscious consumers and regulatory-compliant businesses.

The heavy-duty sandwich press factory has also influenced the market by setting new standards for efficiency. By reducing the time it takes to cook a sandwich, these presses help businesses increase their throughput, which is crucial for maintaining long lines during peak hours. The efficiency of these appliances translates into cost savings for businesses and satisfaction for customers.

The factory’s impact extends beyond the manufacturing process into the supply chain. By streamlining production and distribution, the factory is able to offer competitive pricing while still maintaining high-quality standards. This has allowed for wider market penetration, making heavy-duty sandwich presses accessible to a broader range of businesses.

The environmental consciousness of the heavy-duty sandwich press factory is another market-changing factor. By adopting eco-friendly practices and using sustainable materials, the factory is reducing its carbon footprint and setting an example for other manufacturers. This commitment to sustainability resonates with consumers who are increasingly looking for eco-friendly products.

The factory’s influence is also felt in the training and education it provides to users. With comprehensive manuals and training sessions, the factory ensures that operators can get the most out of their sandwich presses. This investment in customer service has led to higher customer satisfaction and a loyal customer base.

Lastly, the heavy-duty sandwich press factory has spurred the creation of a community around sandwich-making. By hosting culinary events and sharing recipes, the factory has encouraged innovation in sandwich preparation. This has sparked a wave of creativity in the food industry, with chefs and sandwich shops experimenting with new flavors and ingredients.

In summary, the heavy-duty sandwich press factory has had a profound impact on the market by driving innovation, improving safety, enhancing efficiency, and fostering a culture of culinary exploration. Its commitment to quality and sustainability has solidified its position as a leader in the kitchen appliance industry.

In the heart of the manufacturing landscape, the heavy duty sandwich press factory stands as a beacon of innovation, crafting appliances that not only cater to the present but also hint at the future of kitchen technology. These designs are a testament to the factory’s commitment to pushing boundaries and redefining what a sandwich press can be.

The sleek, modern aesthetics of the factory’s latest models are a stark contrast to the bulky, traditional presses of yesteryears. The streamlined design not only enhances the visual appeal but also improves functionality, making it easier for users to achieve that perfect, golden-brown crust on their sandwiches.

One of the standout features of the factory’s offerings is the advanced heating system. These heavy duty sandwich presses are equipped with precision-controlled thermostats that ensure consistent heat distribution across the entire cooking surface. This not only guarantees a uniform cook but also allows for a variety of cooking styles, from crispy to soft, with just a simple adjustment of the temperature setting.

The inclusion of non-stick surfaces is another nod to innovation. These surfaces are not only easy to clean but also durable, reducing the need for excessive oil or butter, thus promoting healthier cooking habits. The factory has even developed a unique coating that is more resistant to wear and tear, ensuring that the sandwich press will remain a reliable kitchen companion for years to come.

The integration of smart technology is where the factory’s designs truly shine. Many of the heavy duty sandwich presses come with built-in timers and audible alerts, making it simple for users to monitor cooking times without the need to hover over the appliance. Some models even feature Bluetooth connectivity, allowing users to control the press remotely via their smartphones, a feature that is particularly appealing to busy individuals or those who want to multitask in the kitchen.

Safety features are paramount in the factory’s design philosophy. The inclusion of automatic shut-off mechanisms and cool-touch handles ensures that users can enjoy their sandwiches without the risk of burns or fires. The factory has also paid close attention to the ergonomics of the appliances, with contoured handles and lightweight construction that make them easy to lift and maneuver.

Innovation extends beyond the physical design to the materials used. The factory has invested in high-quality, food-grade materials that are not only durable but also environmentally friendly. These materials are free from harmful chemicals, ensuring that the sandwich press not only performs well but also contributes to a healthier kitchen environment.

The factory’s focus on sustainability is evident in their commitment to energy efficiency. The heavy duty sandwich presses are designed to use less energy than their predecessors, which not only saves on utility bills but also reduces the carbon footprint of the kitchen.

The factory’s approach to innovation doesn’t stop at the appliance itself. They offer a range of accessories and attachments that can transform the sandwich press into a versatile kitchen tool. From grill plates for vegetables and meats to waffle irons for breakfast treats, the possibilities are endless.

The impact of the factory’s innovative designs on the market is significant. Consumers are increasingly seeking appliances that not only perform well but also offer convenience and style. The factory’s heavy duty sandwich presses have become a staple in many homes, not just for making sandwiches but for experimenting with a variety of recipes.

The factory’s forward-thinking approach has also influenced the competitive landscape. Competitors are now racing to catch up, releasing their own versions of innovative sandwich presses that mimic the features and functionality that have become synonymous with the factory’s brand.

In the realm of commercial kitchens, the factory’s heavy duty sandwich presses have made a substantial impact. Restaurants and cafes are embracing these appliances for their speed, consistency, and ability to produce high-quality sandwiches in large volumes. The factory’s dedication to innovation has set a new standard for the industry, pushing the boundaries of what is considered possible in kitchen appliance design.

As we take a closer look at the factory’s designs, it’s clear that the future of sandwich presses is bright. The integration of smart technology, emphasis on health and safety, and commitment to sustainability all point to a future where kitchen appliances are not just tools but companions that enhance our daily lives. The factory’s heavy duty sandwich presses are not just a glimpse into the future; they are the future, right now.

The heavy-duty sandwich press factory stands at the forefront of innovation, and technology plays a pivotal role in shaping its products. From the precision engineering to the cutting-edge materials used, let’s delve into how technology is revolutionizing the crafting of these robust sandwich makers.

The factory employs state-of-the-art computer-aided design (CAD) software to conceptualize and refine the sandwich press designs. This allows engineers to visualize the products in 3D, ensuring that every aspect is optimized for performance and user comfort. The use of CAD not only speeds up the design process but also reduces the likelihood of manufacturing errors.

In the realm of materials, the factory has made significant strides by integrating advanced materials into the construction of heavy-duty sandwich presses. High-quality stainless steel, known for its durability and resistance to corrosion, is a staple. Additionally, the use of anodized aluminum components enhances the longevity of the press and provides a sleek, modern look.

Precision machinery is at the heart of the factory’s production line. CNC (Computer Numerical Control) lathes and milling machines are used to carve intricate parts with incredible accuracy. This level of precision ensures that the sandwich press is not only sturdy but also provides even pressure distribution across the sandwich, resulting in a perfectly toasted result every time.

Energy efficiency is a key concern, and the factory has responded with technology that reduces power consumption. The inclusion of thermostatic controls ensures that the heat is maintained at optimal levels, reducing the need for constant energy adjustments. This not only saves on energy costs but also contributes to a greener manufacturing process.

Safety features are another area where technology shines. The factory has integrated multiple safety mechanisms into the design of the heavy-duty sandwich presses. Child locks, automatic shut-off features, and heat-resistant handles are just a few examples of how technology is used to protect users from accidents.

The factory also leverages automation to streamline production. Robotic arms are used for tasks such as welding and assembly, which not only increases production speed but also reduces the potential for human error. This automation allows for the consistent output of high-quality sandwich presses, meeting the demands of both retail and commercial markets.

In terms of user experience, the factory has incorporated smart technology into the design. Touchscreen interfaces have replaced traditional dials and buttons, offering users a modern and intuitive way to select their desired cooking settings. This integration of smart technology not only makes the sandwich press more user-friendly but also opens the door for future updates and improvements through software updates.

The factory’s commitment to continuous improvement is evident in its investment in research and development. By staying at the forefront of technological advancements, the factory is able to introduce new features and functionalities to its heavy-duty sandwich presses. For instance, the inclusion of adjustable pressure settings allows users to customize the cooking intensity according to their preferences.

The use of 3D printing technology has also become a part of the factory’s arsenal. Prototyping and creating complex components are made quicker and more cost-effective with this technology. This not only speeds up the design process but also allows for the creation of custom parts that can enhance the functionality of the sandwich press.

Lastly, the factory’s focus on quality control is bolstered by advanced testing equipment. Sensors and analytical tools are used to monitor the performance of the sandwich presses throughout the manufacturing process. This ensures that each unit meets the strictest standards before it leaves the factory.

In crafting heavy-duty sandwich presses, the factory’s reliance on technology is not just about efficiency and quality; it’s about creating a product that stands the test of time and adapts to the evolving needs of consumers. By embracing the latest technological advancements, the factory is not just impacting the market today—it’s shaping the future of kitchen appliances.

The heavy-duty sandwich press has become a staple in many kitchens, and its popularity is on the rise. Let’s delve into why this appliance has captured the hearts and taste buds of consumers.

Its Versatility in CookingOne of the key reasons for the heavy-duty sandwich press’s hit status is its versatility. This kitchen gadget isn’t just for making classic sandwiches; it can sear, toast, and grill a variety of foods. From burgers and paninis to vegetables and meats, the possibilities are endless. Consumers appreciate the ability to prepare multiple dishes with a single tool, saving time and space on their countertops.

Ease of UseThe heavy-duty sandwich press is designed with user convenience in mind. Its non-stick surfaces ensure that food releases easily, preventing messy cleanups. The sleek design with a simple on/off switch and adjustable heat settings make it a breeze to use. Even those who aren’t the most confident in the kitchen can enjoy perfectly toasted sandwiches or grilled cheese with ease.

Customizable Cooking ExperienceWhat sets the heavy-duty sandwich press apart is its ability to offer a customizable cooking experience. The adjustable pressure and temperature controls allow users to achieve the perfect level of crispiness or doneness. Whether you prefer a golden-brown outer crust with a soft, melting center or a well-done burger that’s charred to perfection, the sandwich press can deliver it all.

Healthier Cooking OptionsIn an era where health and wellness are top priorities, the heavy-duty sandwich press provides a healthier alternative to deep-frying. By using less oil and cooking at lower temperatures, this appliance helps to reduce the calorie count and fat content of your favorite meals. Consumers who are looking to eat healthier are drawn to the sandwich press as a tool that can help them achieve their dietary goals.

Durability and Build QualityThe heavy-duty aspect of the sandwich press isn’t just a marketing term; it’s a testament to its durability and build quality. These appliances are often made from high-quality materials like stainless steel and aluminum, which are resistant to rust and corrosion. The solid construction ensures that the press can withstand frequent use without losing its effectiveness, making it a long-term investment for the consumer.

AffordabilityDespite their robust design and advanced features, heavy-duty sandwich presses are surprisingly affordable. This accessibility means that a wide range of consumers, from college students to busy professionals, can enjoy the convenience and culinary possibilities that these appliances offer. The affordability factor has certainly contributed to the sandwich press’s widespread appeal.

Fashionable and StylishIn addition to its practicality, the heavy-duty sandwich press is also a stylish addition to any kitchen. Available in various colors and designs, these appliances can complement different kitchen decors. The modern aesthetic of the sandwich press doesn’t just serve a functional purpose; it also serves as a conversation starter and a statement piece.

Versatile Heat SettingsMany heavy-duty sandwich presses come with a variety of heat settings, allowing users to experiment with different cooking techniques. From low and slow to high and fast, the ability to control the heat ensures that each sandwich or meal is cooked to the consumer’s exact specifications. This level of control over the cooking process is a feature that consumers find extremely appealing.

Simplicity and CleanlinessThe simplicity of the sandwich press is another factor that contributes to its popularity. There are no complicated parts to clean or maintain, and the non-stick surfaces make cleanup a breeze. Consumers value the ease of use and the quickness with which the press can be put away after use, ensuring that their kitchen remains clutter-free.

In conclusion, the heavy-duty sandwich press has become a hit among consumers due to its versatility, ease of use, customizable cooking experience, healthier options, durability, affordability, stylish design, versatile heat settings, simplicity, and cleanliness. As kitchen appliances continue to evolve, it’s clear that the sandwich press has carved out a significant niche in the hearts and homes of many.

In today’s kitchen appliance landscape, the heavy duty sandwich press stands out as a versatile and powerful tool. When compared to traditional grills, it offers a unique set of benefits that cater to the evolving preferences of consumers. Let’s delve into the comparative analysis of these two kitchen giants.

The heavy duty sandwich press is renowned for its compact size and ease of use. It’s a staple in many modern kitchens, thanks to its ability to quickly and efficiently cook sandwiches with a perfect, golden-brown exterior. On the other hand, traditional grills, whether charcoal or gas, are larger, more permanent fixtures that require a considerable amount of space and preparation. This size difference impacts the convenience factor significantly.

When it comes to cooking surface area, traditional grills typically offer more space to cook a variety of foods, not just sandwiches. However, the heavy duty sandwich press excels in its specialized task, ensuring that every sandwich is cooked evenly with consistent pressure. The even distribution of heat is a hallmark of these presses, often leading to a better-tasting, more appealing final product.

The cooking process is another area where heavy duty sandwich presses outshine traditional grills. These presses lock in the flavors and juices of the ingredients, creating a moist, delectable sandwich. Grills, while capable of producing delicious meals, can sometimes dry out the food, particularly if not attended to closely. The precise control over temperature and cooking time is a clear advantage of the sandwich press.

Safety is a crucial factor in kitchen appliances, and here too, the heavy duty sandwich press has a leg up on traditional grills. Grills, especially charcoal models, can be unpredictable and produce flare-ups, posing a risk of burns or fires. The sandwich press, with its enclosed design, minimizes the risk of burns and accidental fires. It also reduces the need for oil, which can be a fire hazard on open grills.

Maintenance and cleaning are often overlooked when considering kitchen appliances, but they play a significant role in the long-term enjoyment of the product. Heavy duty sandwich presses are designed with non-stick surfaces, making them easy to clean after use. This contrasts with traditional grills, which can require more effort to clean due to the charred residue and grease buildup. The ease of maintenance can also contribute to a longer lifespan of the sandwich press.

Portability is another aspect where the heavy duty sandwich press shines. It’s lightweight and compact, allowing for easy storage and transport. This feature is particularly appealing for those who entertain guests or enjoy picnics and outdoor events. Traditional grills, while sturdy and reliable, are not as portable, limiting their use to more permanent setups like a backyard or patio.

In terms of design, heavy duty sandwich presses have seen a surge in innovation. The latest models often come with features like adjustable heat settings, digital temperature controls, and even Bluetooth connectivity for remote operation. These advancements not only enhance the cooking experience but also add a touch of modernity to the kitchen.

Lastly, there’s the matter of price. While traditional grills can be expensive, especially high-end models, the cost of a heavy duty sandwich press is generally more accessible. This affordability makes it a practical choice for budget-conscious consumers who want a reliable appliance for their sandwich needs.

In conclusion, the heavy duty sandwich press vs. traditional grill debate boils down to the specific use case and individual preferences. For those who prioritize convenience, portability, and precision in sandwich preparation, the heavy duty sandwich press is the clear winner. It may not offer the versatility of a grill, but it excels in its intended purpose, making it a hit among sandwich lovers and busy home chefs alike.

In today’s fast-paced world, where convenience meets culinary delight, the heavy-duty sandwich press factory stands as a testament to the evolving landscape of kitchen appliances. This factory’s dedication to quality and sustainability is not just a choice but a necessity in an industry that is increasingly aware of its environmental footprint. From the materials used to the manufacturing processes, every aspect of this factory’s operations reflects a deep commitment to both the consumer and the planet.

The factory’s materials are carefully selected to ensure durability and longevity. High-quality stainless steel is the backbone of their sandwich presses, chosen for its resistance to rust and corrosion. This not only guarantees that the appliances will withstand the test of time but also aligns with the factory’s ethos of sustainability. By using materials that require minimal maintenance and can be recycled at the end of their life cycle, the factory is reducing waste and promoting a circular economy.

In the realm of sustainability, the factory doesn’t just stop at material choice. They have implemented energy-efficient manufacturing practices that significantly reduce their carbon footprint. Advanced machinery is used to streamline production, minimizing energy consumption and waste. This includes state-of-the-art welding and assembly lines that are designed to operate with precision, ensuring minimal material waste.

Moreover, the factory is committed to ethical sourcing. They work with suppliers who adhere to fair trade practices and environmental standards. This ensures that the products are not only high-quality but also produced in a manner that respects the rights of workers and the environment. The factory’s commitment to transparency is evident in their supply chain, which is regularly audited to maintain these high standards.

Quality control is another cornerstone of the factory’s operations. Every sandwich press that leaves the factory is subjected to rigorous testing to ensure it meets the strictest quality standards. This includes testing for heat distribution, durability, and safety features. The factory’s team of skilled technicians and engineers is dedicated to perfecting the design and functionality of each appliance, ensuring that customers receive a product that exceeds expectations.

The factory also invests in continuous improvement, constantly seeking ways to enhance their products and processes. They are at the forefront of integrating smart technology into their sandwich presses, offering features that not only make cooking easier but also provide valuable insights into usage and maintenance. This focus on innovation means that the factory is not just meeting current demands but also preparing for the future.

In terms of sustainability, the factory is proactive in reducing its environmental impact. They have implemented a comprehensive recycling program within the factory, ensuring that all materials used in production are recycled or repurposed. This includes the recycling of packaging materials, which is a significant step towards minimizing waste.

The factory’s commitment to quality and sustainability extends beyond their products. They are also involved in community initiatives that promote environmental education and conservation. By engaging with local schools and organizations, they aim to inspire a new generation of environmentally conscious consumers and future innovators.

In conclusion, the heavy-duty sandwich press factory’s commitment to quality and sustainability is a holistic approach that touches every aspect of their operations. From the materials they choose to the technology they employ, and the initiatives they support in the community, this factory is setting a precedent for the industry. Their dedication to excellence and the environment is not just a trend; it’s a vision for the future of kitchen appliances.

In the ever-evolving landscape of kitchen appliances, the heavy duty sandwich press has emerged as a staple, not just for the culinary enthusiast but for the everyday cook. This compact yet powerful tool has redefined the way we savor our sandwiches, offering a perfect blend of convenience and flavor. Let’s delve into the reasons behind its meteoric rise in popularity.

The sandwich press has become a hit with consumers for several compelling reasons. Its ability to achieve a perfectly toasted, golden-brown exterior while locking in the flavors of the fillings has made it a go-to appliance for those seeking a delightful eating experience. Moreover, the ease of use and the ability to customize each sandwich to one’s liking has added to its charm. From the novice to the seasoned chef, the heavy duty sandwich press has become a kitchen favorite.

One of the key factors that sets heavy duty sandwich presses apart from traditional grills is the level of control they offer. While grills require constant monitoring and flipping to ensure even cooking, sandwich presses do the work for you. The even distribution of heat and the precise timing ensure that each slice of bread is toasted to perfection without the risk of burning. This aspect alone has made the heavy duty sandwich press a convenience that many consumers can’t live without.

The design of a high-quality heavy duty sandwich press is another aspect that has captured the hearts and minds of consumers. These presses often come with non-stick surfaces that make cleaning a breeze, and they feature adjustable heat settings to cater to different types of bread and fillings. Some models even come with unique features like removable grids or adjustable sandwiches, allowing for a wide variety of culinary creations.

The impact of the heavy duty sandwich press factory on the market is significant. These factories are the heartbeat of innovation, constantly pushing the boundaries of what a sandwich press can do. They not only manufacture the devices but also invest in research and development to introduce new features and technologies that enhance the user experience. The market is now flooded with a variety of heavy duty sandwich presses, each with its own set of benefits, thanks to these factories’ commitment to quality and innovation.

Technology plays a pivotal role in crafting heavy duty sandwich presses. From the materials used in the construction to the electronic components that regulate heat, every aspect of these appliances is carefully considered. Advanced heating elements ensure that the sandwich press can maintain consistent temperatures throughout the cooking process, while digital controls provide users with the ability to adjust the heat level with precision. The integration of smart technology is also on the rise, allowing for connectivity and programmability that was once unimaginable.

Consumers are drawn to the heavy duty sandwich press for its versatility. It’s not just limited to making sandwiches; some models can be used to toast bagels, melt cheese, or even grill vegetables. The convenience of having a multipurpose appliance that can handle various tasks without compromising on quality is what has made it a hit in homes across the globe.

When comparing heavy duty sandwich presses to traditional grills, there are several advantages that stand out. The sandwich press is compact and portable, making it ideal for small kitchens or for those who prefer not to clutter their countertops. It also requires less attention and time, as it does the cooking for you. Traditional grills, on the other hand, are larger and more cumbersome, often requiring a dedicated outdoor space and more time to prepare and clean.

The heavy duty sandwich press factory’s commitment to quality and sustainability is evident in their manufacturing processes. They prioritize the use of eco-friendly materials and ensure that their appliances are energy-efficient. This not only benefits the environment but also translates to cost savings for consumers. The factories also focus on creating durable products that can withstand daily use, reducing the need for frequent replacements.

Looking ahead, the future prospects of the heavy duty sandwich press industry are bright. With the rise of health-conscious consumers and the increasing popularity of home cooking, there is a growing demand for convenient and delicious cooking solutions. The industry is expected to see continued innovation, with new features and functionalities being introduced to meet the evolving needs of consumers. From enhanced heat distribution to, the heavy duty sandwich press is poised to become even more integral to modern kitchens.

Market trends indicate a shift towards compact, multi-functional kitchen appliances that offer convenience without compromising on quality. The heavy duty sandwich press fits perfectly into this trend, offering a solution that is both practical and enjoyable. As the industry grows, we can expect to see even more sophisticated designs and technologies that make cooking at home a delightful experience for everyone.