Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

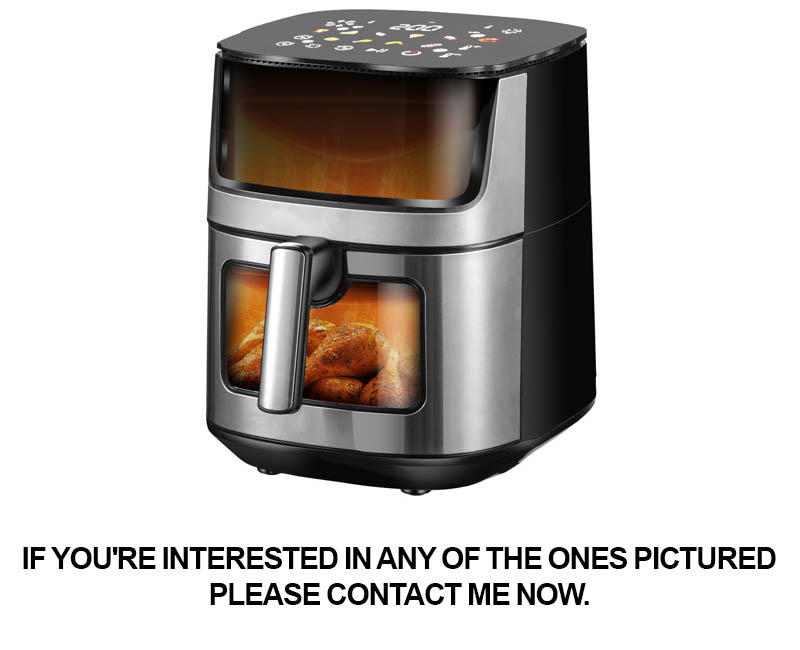

Navigating the world of air fryer manufacturers can be daunting, but making the right choice is crucial for ensuring top-notch quality and customer satisfaction. As you delve into the sea of options, it’s essential to weigh the pros and cons, consider your specific needs, and ultimately, make a decision that aligns with your expectations and budget. This process involves evaluating various factors, from the manufacturer’s reputation and product quality to pricing and customization options. Let’s explore these considerations to help you make an informed decision.

When it comes to investing in a new kitchen appliance, the choice of manufacturer can be just as crucial as the appliance itself. This is particularly true for air fryers, a popular and health-conscious cooking solution that’s gaining traction in homes and commercial kitchens alike. Navigating the market to find a reliable air fryer factory is essential for several reasons:

Quality Assurance: A reputable factory is committed to producing high-quality air fryers that are durable and reliable. This means fewer repairs and replacements for you, saving both time and money in the long run.

Innovation and Technology: The air fryer market is constantly evolving, with new features and technologies being introduced regularly. A reliable factory not only keeps up with these advancements but also leads the way in innovation, offering you cutting-edge products.

Safety Standards: Cooking appliances can be hazardous if not built to the highest safety standards. A trustworthy factory adheres to international safety regulations, ensuring that your air fryer is not only effective but also safe to use.

Customer Support: A reliable air fryer factory understands the importance of excellent customer service. From pre-sales inquiries to after-sales support, they should be there to assist you every step of the way.

Customization Options: Whether you’re a small business owner looking for a unique branding solution or a consumer with specific needs, a reliable factory offers customization options that cater to your requirements.

Sustainability: In an era where sustainability is a top priority, a factory that uses eco-friendly materials and practices not only contributes to a greener planet but also offers you a more sustainable product.

Warranty and Service: A robust warranty and a reliable service network are indicators of a manufacturer’s confidence in their product. This means that if anything goes wrong, you’ll have the peace of mind knowing that help is just a call away.

Market Trends: A reliable air fryer factory is well-versed in current market trends and consumer preferences. This knowledge allows them to anticipate future needs and develop products that will stand the test of time.

Brand Reputation: The reputation of a factory can speak volumes about the quality of their products. Look for manufacturers with a strong track record and positive customer feedback.

Cost-Effectiveness: While it’s tempting to go for the cheapest option, investing in a reliable air fryer factory can be cost-effective in the long term. Quality products often have a longer lifespan and require less maintenance.

In summary, choosing a reliable air fryer factory means investing in an appliance that will not only meet your current needs but also adapt to future trends. It’s about ensuring that you have a product that is not just efficient but also safe, durable, and innovative. So, when you’re on the hunt for your next air fryer, take the time to research and select a factory that you can trust to deliver on these critical aspects. After all, the right air fryer factory can make all the difference in your cooking experience.

Finding the right air fryer factory is crucial for ensuring the quality and reliability of the products you’ll be dealing with. Here are some key qualities to consider when evaluating potential manufacturers:

Experience and ExpertiseAn experienced air fryer factory has likely honed its processes over years, understanding the nuances of design, materials, and manufacturing techniques. Look for a manufacturer that has been in the industry for at least a decade, as this indicates a track record of success and a deep understanding of customer needs.

Advanced Manufacturing CapabilitiesThe factory should have state-of-the-art machinery and equipment to produce air fryers. Modern technology not only ensures efficiency but also allows for precision in manufacturing, reducing defects and improving the overall quality of the products.

Quality Control MeasuresA reputable air fryer factory will have stringent quality control measures in place. This includes regular inspections, testing at various stages of production, and adherence to international quality standards. It’s important to ask about their quality control processes and certifications.

Design InnovationThe ability to innovate is crucial in the rapidly evolving kitchen appliance market. A factory that invests in research and development is more likely to produce cutting-edge air fryers with unique features that stand out in the market.

Customization OptionsNot all businesses need the same air fryer. A flexible manufacturer should offer customization options, allowing you to tailor the design, size, and features of the air fryers to meet your specific requirements or those of your customers.

Certifications and ComplianceLook for factories that hold certifications from recognized bodies, such as ISO, CE, or UL. These certifications ensure that the air fryers meet safety, health, and environmental standards, giving you peace of mind when dealing with regulatory requirements.

Sustainability PracticesIn today’s market, sustainability is a key concern. An air fryer factory that practices eco-friendly manufacturing processes, uses recycled materials, and has a commitment to reducing waste can be a more responsible choice for your business.

Supply Chain ManagementThe efficiency of a factory’s supply chain can greatly impact lead times and the availability of products. A well-managed supply chain ensures timely delivery and reduces the risk of stockouts, which is crucial for maintaining customer satisfaction.

Customer Support and ServiceExcellent customer service is essential for building long-term relationships. An air fryer factory that offers robust after-sales support, including technical assistance and product warranties, demonstrates its commitment to customer satisfaction.

Financial StabilityIt’s important to work with a factory that is financially stable. This reduces the risk of disruptions in production or delays in delivery. Check for any signs of financial instability, such as recent layoffs or a history of late payments to suppliers.

Market UnderstandingA factory that truly understands the market will be able to anticipate trends and adapt to changing consumer preferences. Look for a manufacturer that keeps up with industry news, attends trade shows, and engages with industry experts.

Feedback from Other CustomersThe experiences of other businesses can provide valuable insights. Ask for references and case studies from previous clients to get a sense of the factory’s reliability and the quality of its products.

Technology IntegrationModern air fryer factories are integrating advanced technologies such as IoT (Internet of Things) to improve production efficiency and product features. A manufacturer that leverages technology can offer more sophisticated and connected air fryer products.

Environmental ResponsibilityConsider a factory that is committed to reducing its environmental footprint. This could involve energy-efficient operations, water conservation, and responsible disposal of manufacturing waste.

Long-Term Business Relationship PotentialFinally, think about the potential for a long-term business relationship. A factory that is committed to growing with you and adapting to your evolving needs can be a valuable partner for your business.

By considering these qualities, you can ensure that the air fryer factory you choose aligns with your business goals and provides you with high-quality, innovative products that meet the demands of your market.

Navigating the sea of air fryer manufacturers, it’s crucial to dive deep into the reputation and reviews that precede each factory. Here’s how to sift through the noise and find the gems in the industry.

Understanding the Market LandscapeStart by getting a sense of the market landscape. Are there specific regions known for their expertise in air fryer manufacturing? Knowing this can help you narrow down your search to areas with a higher concentration of reputable factories.

Checking Online ReviewsOnline reviews can offer a snapshot of what past clients think about a factory’s products and services. Look for platforms where customers have left detailed feedback. Are there common threads in the reviews that highlight quality, durability, or customer service?

Analyzing Manufacturer ProfilesVisit the official websites of the air fryer factories you’re considering. A well-maintained website can be a sign of a professional operation. Check for their company history, mission statement, and any accolades or certifications they’ve received.

Customer TestimonialsBeyond reviews, customer testimonials can provide personal insights. Look for sections on the manufacturer’s site where customers share their experiences. Pay attention to how the factory responds to negative feedback—this can reveal a lot about their customer relations.

Industry Awards and RecognitionsAwards and recognitions from trade organizations or industry associations can be a strong indicator of a factory’s standing. Research if the factory has won any awards for innovation, quality, or customer satisfaction.

Networking within the IndustryEngage with industry forums, social media groups, and professional networks. Often, you can learn about reputable factories through word-of-mouth from peers and colleagues who have direct experience with the manufacturers.

Seeking Input from Distributors and RetailersDistributors and retailers who work closely with air fryer manufacturers can provide valuable insights. They may have firsthand knowledge of the reliability and quality of various factories’ products.

Reviewing Product Ratings and ComparisonsLook for websites or publications that compare air fryers from different manufacturers. These reviews often go beyond individual experiences to provide a broader assessment of each factory’s offerings.

Checking for Legal Issues and DisputesA thorough search for any legal issues or disputes involving the factory can be revealing. Use online databases to see if there have been any recent lawsuits or regulatory actions that might impact the factory’s reputation.

Understanding the Supply ChainThe reputation of an air fryer factory isn’t just about the products—it’s also about the supply chain. Research how the factory sources its components and whether they adhere to ethical and sustainable practices.

Assessing Post-Sales SupportThe quality of post-sales support can be a telling sign of a factory’s commitment to customer satisfaction. Look for information on warranty policies, repair services, and customer support responsiveness.

Monitoring Online Presence and Social MediaA strong online presence and active social media engagement can indicate a factory’s dedication to maintaining its brand and customer relationships. Keep an eye on how they communicate with their audience.

Considering Longevity in the MarketThe length of time a factory has been in business can be an indicator of its stability and experience. Older manufacturers may have a deeper understanding of the market and its trends.

By thoroughly researching industry reputation and reviews, you can build a clearer picture of each air fryer factory’s standing. This diligence can lead to a more informed decision and ultimately, a more reliable partnership with the right manufacturer.

Understanding the intricacies of product quality and innovation in the context of an air fryer factory is crucial for making an informed decision. Here’s a delve into what to look for:

Material Selection: The foundation of quality lies in the materials used. A reputable air fryer factory should prioritize high-quality, food-grade materials that are durable and safe. Look for stainless steel components for their longevity and resistance to corrosion, and ensure that non-stick coatings are free from harmful chemicals like PFOA and PFAS.

Design and Engineering: The design of an air fryer not only impacts its aesthetics but also its functionality. A well-engineered product will have a thoughtful design that maximizes efficiency, minimizes noise, and ensures even cooking. Pay attention to the heating elements, fan placement, and cooking basket design, as these factors greatly influence the performance of the appliance.

Cooking Performance: Testimonials and reviews can provide insights into how well the air fryers perform. Look for consistent praise for even cooking, minimal oil usage, and the ability to handle a variety of recipes. A reliable factory will often have a range of models to cater to different cooking needs, from crispy French fries to tender roast chicken.

Safety Features: Safety should never be compromised. Check for features like automatic shut-off, overheat protection, and non-slip bases. A good air fryer factory will incorporate these safety measures to prevent accidents and protect users.

Innovation in Technology: The air fryer market is constantly evolving, with new technologies emerging to improve cooking experiences. Look for features like smart controls, which allow for remote monitoring and adjustments via an app. Advanced temperature control systems can also ensure that food is cooked to perfection every time.

Certifications and Standards: A reputable factory will comply with international safety and quality standards. Look for certifications like CE, UL, or ETL, which indicate that the air fryers meet or exceed safety requirements. These certifications also ensure that the products have been tested for performance and safety.

Customer Feedback: Real customer experiences can be invaluable. Check out online reviews, social media forums, and product review websites. Look for patterns in feedback regarding the longevity of the product, customer service, and overall satisfaction.

Warranty and After-Sales Service: A strong warranty and reliable after-sales service are indicators of a manufacturer’s confidence in their product. A good air fryer factory will offer a comprehensive warranty that covers defects and malfunctions, along with responsive customer service for any issues that may arise.

Customization and Special Orders: A factory that offers customization options shows a commitment to meeting specific customer needs. This could include different sizes, power levels, or additional features. The ability to tailor air fryers to specific market demands is a sign of flexibility and innovation.

Sustainability Practices: In an era where sustainability is a growing concern, it’s worth considering how the air fryer factory operates. Look for manufacturers that use environmentally friendly materials, have energy-efficient production processes, and are committed to reducing their carbon footprint.

By carefully evaluating these aspects, you can gain a comprehensive understanding of the quality and innovation behind the air fryers produced by a factory. This thorough research will help you choose a product that not only meets your cooking needs but also stands out in terms of safety, technology, and customer satisfaction.

Understanding the intricacies of safety standards in the manufacturing of air fryers is crucial, as it directly impacts the end-user’s experience and the brand’s reputation. Here’s a deep dive into what you should look for:

The Importance of Safety CertificationsManufacturers often display safety certifications, such as CE, UL, or ETL, which are recognized across various regions. These certifications signify that the air fryer has been tested for electrical safety, fire resistance, and user protection. It’s essential to verify that the factory you’re considering holds these certifications, as they are not easily obtained and demonstrate a commitment to quality.

Material Selection MattersThe materials used in the construction of an air fryer are fundamental to its safety. High-quality, heat-resistant materials like stainless steel, anodized aluminum, and durable plastics are preferred. Be sure to ask about the materials used and how they meet specific safety standards. Poor quality materials can lead to overheating, melting, or even the release of harmful chemicals when exposed to heat.

Thermal Protection and Overheating PreventionA reliable air fryer factory should prioritize thermal protection mechanisms to prevent overheating. This can include temperature sensors, automatic shut-offs, and heat-resistant coatings. These features ensure that the air fryer operates safely within its designed parameters, reducing the risk of fires or burns.

Electrical Components and WiringThe integrity of electrical components and wiring is critical in any kitchen appliance. Check that the air fryer’s electrical design complies with the relevant safety standards, such as proper grounding, wiring insulation, and the use of high-temperature-resistant cables. Faulty electrical work can lead to shorts, fires, or electric shocks, making it a significant concern.

Testing and Quality Control ProtocolsA reputable factory will have stringent testing and quality control protocols in place. This includes both in-process checks and final product inspections. Look for evidence of these protocols, such as detailed test reports, certifications from independent laboratories, and a transparent quality assurance process.

User Safety FeaturesModern air fryers come with various safety features designed to protect the user. These can include cool-touch handles, child locks, and non-slip bases. Ensure that the factory’s products are equipped with these features and that they are designed to be intuitive and user-friendly.

Fire Safety ConsiderationsSince air fryers can reach high temperatures, fire safety is paramount. The factory should have measures to prevent sparks or heat buildup, especially in the motor and heating elements. Additionally, the air fryer’s design should facilitate safe operation, with no flammable materials close to the heating elements.

Durability and LongevityA reliable air fryer should be durable and long-lasting. This includes not just the materials used but also the design’s ability to withstand repeated use without compromising safety. Look for brands that offer long warranties, as this can be an indicator of their confidence in the product’s safety and quality.

Regulatory ComplianceDifferent countries have different regulatory requirements for kitchen appliances. A factory that complies with a range of international standards, such as those in the United States, Europe, and China, shows a commitment to safety. Verify that the factory adheres to these standards, and ask about their experience in exporting to different markets.

Consumer Feedback and Incident ReportsFinally, consider the feedback from actual consumers and any reported incidents. Look for patterns of safety issues or positive comments regarding the air fryer’s safety features. Online reviews, forums, and consumer protection websites can be valuable resources in this regard.

By thoroughly evaluating these aspects, you can ensure that the air fryer factory you choose is not only producing a quality product but also one that is safe for its users. This diligence will pay off in the long run, both for the consumer and for the manufacturer’s reputation.

Understanding the importance of customer testimonials and case studies is akin to getting a firsthand look into the experiences of others who have already worked with a particular air fryer factory. These insights can be invaluable in making an informed decision about where to source your products. Here’s a deeper dive into why these resources are so crucial:

Real-Life Feedback: Testimonials provide real-life feedback from customers who have purchased air fryers from the factory. This unfiltered feedback can give you a sense of the product’s reliability and the company’s customer service.

Quality Assurance: By reading through customer reviews, you can gauge the quality of the air fryers. Look for consistent comments about durability, performance, and the overall user experience.

Problem Solving: Case studies often showcase how a factory has addressed specific challenges or customized products to meet unique customer needs. This can be particularly useful if you’re looking for a supplier who can adapt to your specific requirements.

Success Stories: Positive testimonials and successful case studies can be powerful marketing tools. They not only reassure potential buyers but also demonstrate the factory’s ability to deliver on promises.

Understanding Customer Satisfaction: Customer satisfaction is a key indicator of a company’s performance. High ratings and glowing reviews can indicate that the factory is committed to customer happiness.

Identifying Trends: By analyzing multiple testimonials and case studies, you can identify trends in customer feedback. This can help you understand what aspects of the air fryers are most appreciated and which areas may need improvement.

Comparative Analysis: If you’re considering multiple air fryer factories, comparing their testimonials and case studies can help you make a more informed choice. Look for patterns in the feedback and see how each factory’s offerings stack up against the others.

Building Trust: Testimonials and case studies can build trust in a brand. When potential clients see that others have had positive experiences, it can make them more comfortable in doing business with that factory.

Learning from Failures: While it’s natural to focus on positive reviews, it’s also important to look for any negative feedback or instances where the factory may have faced challenges. How they handled these situations can provide insight into their problem-solving capabilities.

Longevity and Reliability: Testimonials that span a long period of time can indicate the longevity of the products and the reliability of the factory. It’s not uncommon for satisfied customers to share their experiences over several years.

Engagement with the Community: Look for testimonials and case studies that engage with the broader community. This could be through sustainability initiatives, community support, or involvement in industry events. It can give you a sense of the factory’s social responsibility and commitment to the industry.

Expert Endorsements: Sometimes, testimonials come from industry experts or influencers. These endorsements can carry significant weight and can be a strong indicator of product quality and factory reputation.

Consistency in Service: A consistent theme in testimonials and case studies can be a sign of a factory that maintains high standards across its operations. Look for consistent comments about the speed of delivery, the professionalism of the staff, and the ease of communication.

Customization and Flexibility: Case studies that highlight a factory’s ability to customize products or offer flexible solutions can be particularly valuable if you’re looking for a supplier that can cater to a diverse range of needs.

Long-Term Relationships: Finally, testimonials and case studies that speak to long-term relationships with clients can be a testament to the factory’s commitment to building and maintaining strong business connections.

By thoroughly examining the testimonials and case studies of an air fryer factory, you can gain a comprehensive understanding of their product quality, innovation, customer service, and overall business practices. This research can be a pivotal step in selecting a reliable partner for your air fryer manufacturing needs.

Understanding the intricacies of an air fryer factory’s production capacity and lead times is crucial for businesses looking to establish a reliable partnership. Here’s a breakdown of what to consider:

Assessing Production Volume and ScalabilityFactories with a high production volume often indicate they can handle large orders. Look for evidence of scalability, as this suggests the factory can increase output if your business grows. Check if they have the necessary machinery and workforce to expand their production line.

Diverse Product Range and CustomizationA factory that offers a wide range of air fryer models shows versatility in their manufacturing capabilities. This can be beneficial if you’re looking for different sizes, features, or even custom designs. Ensure they can cater to various market needs and preferences.

Efficiency in Production ProcessesEfficient production processes mean quicker lead times and potentially lower costs. Look for signs of automation, optimized workflows, and skilled labor that contribute to a smooth and rapid production line. This efficiency can translate into timely delivery for your customers.

Lead Times and Delivery SchedulesEvaluate the factory’s standard lead times and their ability to meet deadlines. A reliable factory will provide clear delivery schedules and communicate any potential delays. Consider the impact of lead times on your own business operations and customer satisfaction.

Inventory ManagementEfficient inventory management is key to ensuring that the factory can fulfill orders without long waiting periods. Look into their stock levels and how they manage inventory to avoid stockouts or overstocking issues. A well-managed inventory system can prevent costly delays.

Order Fulfillment FlexibilityConsider how flexible the factory is with order fulfillment. Can they accommodate rush orders or adjust production schedules to meet urgent needs? This flexibility is especially important if your business operates in a fast-paced market or faces unexpected demand spikes.

Long-Term Partnership PotentialIf you’re looking for a long-term supplier, consider the factory’s capacity to handle sustained production levels. A factory that can consistently meet your volume requirements over time is more likely to be a reliable partner.

Quality Control and AssuranceThe factory’s ability to maintain quality control while scaling production is essential. High-quality products are crucial for customer satisfaction and repeat business. Ensure they have robust quality control measures in place that don’t falter as production volume increases.

Communication and TransparencyA factory that communicates effectively about production capacity and lead times is a good sign. Regular updates and transparency in their production process can help you plan your business operations more effectively.

Reviewing Previous OrdersLook at the history of orders they’ve fulfilled for similar clients. How did they handle past orders, especially large or complex ones? This can give you insights into their reliability and how they manage production and delivery under different circumstances.

Certifications and AccreditationsCheck if the factory holds relevant certifications or accreditations that demonstrate their adherence to industry standards. This can include quality management systems, environmental standards, and safety regulations.

Financial StabilityA financially stable factory is more likely to maintain consistent production and delivery. Look into their financial health and stability to gauge their long-term commitment to meeting production demands.

By carefully considering these aspects, you can ensure that the air fryer factory you choose is not only capable of meeting your current production needs but also has the potential to grow with your business and maintain a high level of quality and reliability.

Understanding the nuances of customization options in the manufacturing sector is crucial, especially when dealing with specialized products like air fryers. Customization can range from minor design tweaks to comprehensive modifications that cater to specific market demands or customer preferences. Here’s a closer look at what you should consider when exploring customization options for your air fryer products.

Design FlexibilityThe ability to modify the design of an air fryer can be a game-changer. It allows for branding integration, where your company’s logo can be prominently displayed. It also includes options like color changes, which can be tailored to match kitchen aesthetics or specific marketing campaigns.

Functionality AdjustmentsNot all customers have the same needs. Some might require a model with additional features, such as a larger capacity, adjustable temperature settings, or even a built-in timer. Exploring customization options means understanding what your target market values and adapting the product accordingly.

Material ChoicesThe materials used in manufacturing an air fryer can significantly impact its durability, safety, and environmental impact. Customization might involve selecting different types of plastics, metals, or non-stick coatings. Each material has its own set of benefits and drawbacks, so knowing the specifics is key.

Energy EfficiencyAs sustainability becomes a more significant concern, offering energy-efficient models can be a selling point. Customization might include integrating advanced technologies that reduce energy consumption or using materials that enhance the appliance’s energy efficiency.

Sustainability FocusCustomization can extend to eco-friendly practices, such as using recycled materials or designing the product for easier recycling at the end of its life. This not only appeals to environmentally conscious consumers but also positions the brand as a leader in sustainability.

Regulatory ComplianceDifferent regions have varying regulations regarding product safety and labeling. Customizing air fryers to meet these specific requirements can be vital. This might involve certifications, specific labeling, or even compliance with local electrical standards.

Packaging CustomizationThe packaging is often the first point of contact with the customer. Custom packaging can enhance brand recognition and provide a better unboxing experience. It might include features like secure packaging, clear product information, and even eco-friendly materials.

Volume and Speed of ProductionCustomization might also involve adjusting production volumes and lead times. This is especially important if you’re targeting a specific market event or season. Understanding the factory’s capacity to handle these changes efficiently is crucial.

Quality Control ProtocolsCustomization doesn’t mean compromising on quality. It’s essential to ensure that any changes to the product design or materials don’t affect its performance or safety. Factories should be able to demonstrate robust quality control measures for customized orders.

Customer Service and SupportThe level of customer service offered by the manufacturer is another aspect of customization. This includes everything from handling inquiries about custom options to providing after-sales support. A manufacturer that values customer satisfaction will likely offer comprehensive support for customized products.

Pricing and Cost AnalysisCustomization often comes with a price tag, and it’s essential to understand the cost implications. This includes not just the product cost but also any additional expenses for design changes, materials, and compliance adjustments. A thorough cost analysis can help in making informed decisions.

Long-Term PartnershipsWhen exploring customization options, it’s also wise to consider the potential for long-term partnerships with the manufacturer. A factory that is flexible and reliable in handling custom orders can become a valuable ally in your product development journey.

Feedback LoopFinally, a good customization process includes a feedback loop. After the product is in the market, it’s important to gather data and customer feedback to understand how well the customized features are received. This information can be invaluable for future iterations and improvements.

In summary, exploring customization options for air fryers involves a comprehensive analysis of design, functionality, materials, sustainability, compliance, packaging, production capabilities, quality control, customer service, pricing, and the potential for long-term partnerships. It’s a complex process that requires careful consideration to ensure that the end product not only meets the needs of your customers but also aligns with your brand values and business goals.

Understanding the importance of a reliable air fryer factory lies in the quality and innovation they bring to the market. When you’re in the market for a new air fryer, you want to ensure that the factory you’re dealing with not only produces high-quality products but also stays ahead of the curve with innovative features. Let’s delve into the specifics of what to look for in an air fryer factory.

In the realm of air fryers, reputation speaks volumes. Look for manufacturers that have a history of producing reliable and safe products. Check industry forums, consumer reviews, and social media to gauge the general perception of the factory. Word of mouth can be incredibly valuable, as it often comes from real customers who have had firsthand experiences with the products.

Product quality is paramount, and it’s not just about the materials used but also the design and functionality. A reputable air fryer factory will prioritize durability and user convenience. Inspect the product specifications, read customer testimonials, and look for certifications that assure compliance with safety and quality standards.

Safety is a non-negotiable factor. When evaluating an air fryer factory, ensure that their products adhere to the latest safety regulations and standards. This includes electrical safety, fire resistance, and the use of non-toxic materials. Look for evidence of certifications from recognized bodies such as UL, CE, or ETL.

Testimonials and case studies can provide insights into the real-world performance of the air fryers. Look for success stories from businesses or consumers who have used the products. These stories can give you a sense of how the air fryers perform under various conditions and what kind of value they offer.

Production capacity and lead times are crucial for businesses looking to scale up or meet tight deadlines. A factory with robust production capabilities can handle large orders without compromising on quality. Check if the factory has the necessary machinery and workforce to maintain a high output while ensuring that each product meets the required standards.

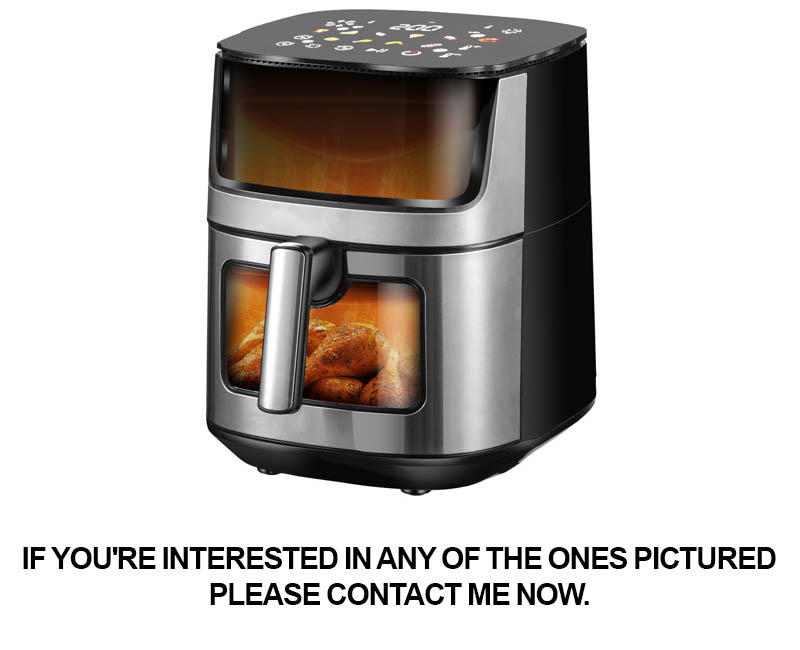

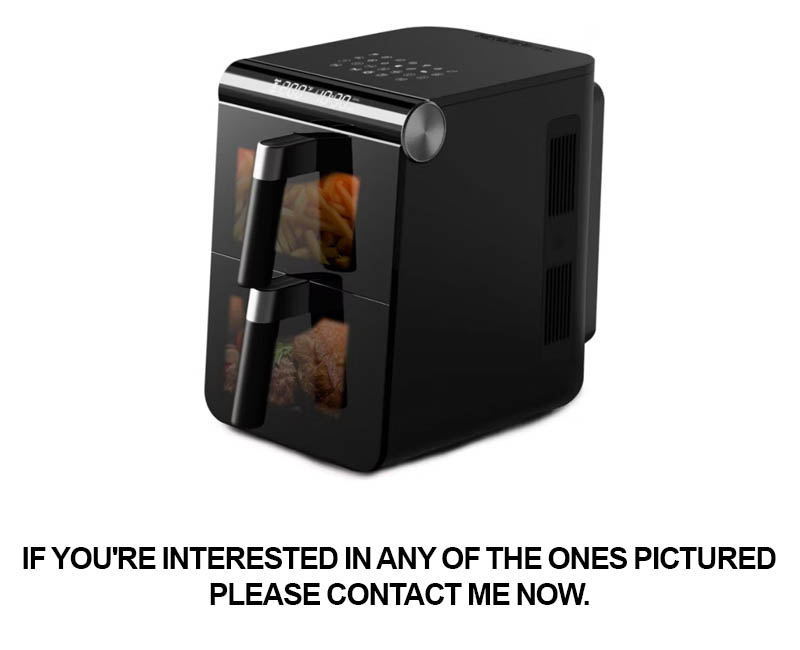

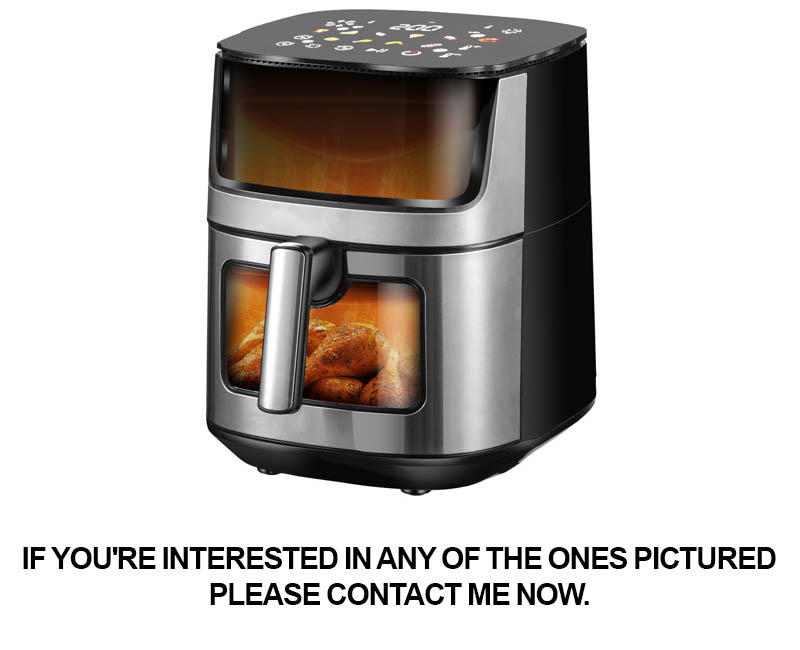

Customization options can be a game-changer, especially for businesses looking to differentiate their products or cater to specific market needs. A good air fryer factory will offer a range of customization services, from branding and color options to specific features and sizes. This flexibility allows for a more tailored product that can resonate with a broader customer base.

When it comes to pricing and value for money, it’s essential to compare apples to apples. Look for factories that offer competitive pricing without cutting corners on quality. Consider the overall value you’re getting in terms of features, durability, and customer service. Sometimes, a slightly higher price can mean a significantly better investment in the long run.

To get a comprehensive understanding of pricing and value, it’s helpful to look at the cost of ownership over time. This includes not just the initial purchase price but also maintenance, repair costs, and potential savings from energy efficiency. A factory that offers a good balance between cost and performance is likely to provide the best value for money.

When comparing pricing, be wary of factories that offer unusually low prices. This could be a sign of poor quality or substandard materials. It’s important to find a middle ground where the price reflects the quality and innovation of the product.

Finally, consider the value that comes with the purchase. Is the factory known for excellent customer service? Do they offer warranties or after-sales support? These factors can add significant value to your investment and help ensure that you’re getting the most out of your purchase.

Remember, the right air fryer factory can be the difference between a successful product launch and one that falls short. Take the time to thoroughly research and evaluate your options to ensure that you’re partnering with a manufacturer that meets your quality standards, offers innovative solutions, and provides excellent value for your investment.

Navigating through the myriad of options and considerations, making the final decision can feel like a daunting task. Here’s how you can approach it:

Consider the Overall FitThink about how well the air fryer factory aligns with your business goals and values. Does their approach to sustainability resonate with your brand’s ethos? Do they prioritize customer satisfaction, which is crucial for long-term partnerships?

Weigh the Pros and ConsTake a moment to jot down the advantages and disadvantages of each potential air fryer factory. Look at factors like product quality, pricing, delivery times, and customer service. This exercise can help you visualize which option is more aligned with your needs.

Trust Your InstinctsSometimes, the decision isn’t just about the data; it’s about your gut feeling. Have you had a positive interaction with the factory’s representatives? Do you feel confident in their ability to meet your expectations? Trusting your instincts can be as important as analyzing the facts.

Check References and RecommendationsAsk for references from past or current clients. Speaking directly with them can provide insights into the factory’s reliability and performance. Additionally, if you’re part of a larger network or community, recommendations from peers can be invaluable.

Evaluate the Contract and TermsThe contract is where the rubber meets the road. Look closely at the terms, including payment schedules, minimum order quantities, and any clauses that might affect your business. Ensure that the contract reflects the agreement you’ve reached and protects your interests.

Understand the Post-Purchase SupportA reliable air fryer factory should offer support beyond the sale. Consider what kind of after-sales service they provide, including warranty, technical assistance, and parts availability. This support can be a significant factor in the long-term success of your partnership.

Consider the Future PotentialThink about the potential for growth and collaboration. Will this factory be able to scale with your business? Can they offer new products or services that might complement your offerings? Choosing a partner who can grow with you can save you time and resources in the future.

Be Mindful of the Total Cost of OwnershipWhile price is a significant factor, it’s not the only one. Consider the total cost of ownership, including shipping, taxes, and any additional fees. Sometimes, a slightly higher upfront cost can translate into long-term savings due to better quality, reliability, and service.

Seek Legal Advice if NecessaryIf the decision is complex or involves a large financial investment, don’t hesitate to seek legal advice. A lawyer can review the contract and help ensure that you’re not missing any critical details that could impact your business.

Reflect on the Decision-Making ProcessAfter gathering all the information and considering all the factors, take a step back and reflect on the decision-making process. Were you thorough in your research? Did you rely too heavily on one aspect, like price, over others? Reflecting on your process can help you understand how you arrived at your decision and ensure you’re making an informed choice.

Trust in Your DecisionOnce you’ve gone through all these steps and feel confident in your decision, trust in it. The final decision is a leap of faith, and while there’s always a degree of uncertainty, having a clear rationale and a well-informed process can give you the peace of mind to move forward. Remember, the right choice for one business might not be the right choice for another, so trust that you’ve made the best decision for your unique situation.