Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

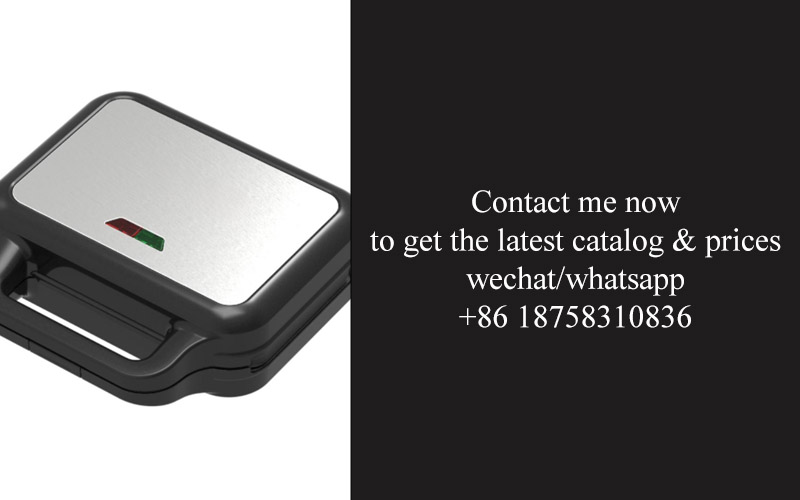

In the bustling world of fast-food and café culture, the sandwich press has become an indispensable tool for creating those mouthwatering, perfectly toasted sandwiches. But with so many options on the market, how do you choose the right one for your business? That’s where the NSF approval comes into play, promising not just quality but also safety and compliance. Let’s delve into the reasons why investing in an NSF approved commercial sandwich press could be a game-changer for your establishment.

The NSF Approval: A Benchmark of Quality and Safety in Commercial Sandwich Presses

The NSF (National Sanitation Foundation) Approval is more than just a certification; it’s a seal of excellence that signifies a product has met stringent health and safety standards. In the competitive world of commercial kitchen equipment, especially for sandwich presses, the NSF mark is a beacon of trustworthiness. Here’s why this approval is so crucial:

Ensuring Compliance with Industry RegulationsThe NSF Certification is recognized globally as a mark of compliance with public health standards. For businesses operating in the foodservice industry, adhering to these regulations is not just a legal requirement but also a moral one. An NSF Approved commercial sandwich press guarantees that the equipment meets the highest standards for safety, sanitation, and operational efficiency.

Guaranteeing Food SafetyFood safety is paramount in the foodservice industry. The NSF Approval process includes rigorous testing for materials used in the sandwich press, ensuring that they are non-toxic and do not leach harmful substances into the food. This is particularly important for a sandwich press, where direct contact with food is constant. The approval process also covers the design and construction of the press to prevent cross-contamination and ensure the integrity of the food being cooked.

Enhancing Consumer ConfidenceCustomers look for reassurance when dining out or purchasing food from a commercial establishment. The NSF mark is widely recognized and associated with quality and safety. By using an NSF Approved sandwich press, businesses can build trust with their customers, knowing that they are providing a safe and hygienic dining experience.

Reducing Liability and RiskIn the event of a foodborne illness outbreak, the responsibility often falls on the establishment’s management. By using an NSF Approved commercial sandwich press, businesses mitigate the risk of such incidents. The approval process includes a thorough evaluation of the equipment’s ability to prevent the growth and spread of bacteria, thereby reducing the potential for liability claims.

Longevity and ReliabilityThe NSF Certification process also evaluates the durability and reliability of the sandwich press. This means that businesses can expect their equipment to last longer, perform consistently, and require fewer repairs or replacements. The reliability of the equipment translates into cost savings and operational efficiency over time.

Innovation and Continuous ImprovementThe NSF Approval is not a one-time achievement; it requires ongoing compliance and adherence to the latest industry standards. This means that manufacturers of NSF Approved sandwich presses are committed to innovation and continuous improvement. They are more likely to invest in research and development to ensure their products stay ahead of the curve in terms of safety, functionality, and design.

Global Recognition and AcceptanceThe NSF mark is recognized worldwide, which is particularly beneficial for businesses that operate in multiple countries or plan to expand internationally. The global acceptance of the NSF Approval simplifies the process of meeting local health and safety standards in various markets.

Eco-Friendly and Sustainable PracticesThe NSF Certification also considers the environmental impact of the sandwich press. This includes evaluating the materials used in the manufacturing process and the product’s lifecycle. By choosing an NSF Approved sandwich press, businesses are not only investing in their customers’ health but also in the planet’s well-being.

In conclusion, the NSF Approval is a vital factor to consider when investing in commercial sandwich presses. It represents a commitment to safety, quality, and reliability, which are non-negotiable in the foodservice industry. By choosing an NSF Approved product, businesses can rest assured that they are providing a safe dining experience, reducing their risk of legal issues, and setting a high standard for their competitors.

Commercial sandwich presses have come a long way since their humble beginnings. Once a simple kitchen gadget, these devices have transformed into an essential piece of equipment in many professional kitchens. Let’s delve into the evolution of the commercial sandwich press and how it has adapted to meet the demands of modern foodservice.

The earliest sandwich presses were nothing more than heavy cast-iron or steel cookware, often used for making grilled sandwiches at home. They featured a flat top that was heated over a stove and a bottom plate that pressed the bread down for even cooking. These presses were labor-intensive and time-consuming, requiring constant monitoring to ensure even heat distribution.

As the foodservice industry grew, so did the need for more efficient cooking methods. The first electric sandwich presses emerged in the early 20th century, introducing a level of convenience that revolutionized the way sandwiches were made. These early models were still quite rudimentary, often lacking precise temperature controls and adjustable pressure settings.

The 1950s and 1960s saw a surge in the popularity of the commercial sandwich press. The introduction of thermostats and adjustable pressure allowed for greater control over the cooking process, ensuring that every sandwich was cooked to perfection. This era also brought about the development of sandwich presses with non-stick surfaces, making them easier to clean and maintain.

As technology advanced, sandwich presses became more sophisticated. The inclusion of timers and audible alerts marked significant improvements, as they provided chefs with the ability to set precise cooking times and be alerted when the sandwich was ready. These innovations not only increased efficiency but also reduced the risk of overcooking or burning the bread.

In the late 20th century, sandwich presses began to incorporate features that catered to the diverse needs of the foodservice industry. Some models included adjustable temperature settings, allowing for the cooking of various types of bread, from white to whole-grain, with ease. Others featured adjustable pressure controls, which were especially useful for creating a perfect crust on the outside while keeping the inside soft and moist.

The rise of health-conscious consumers and the demand for customizable menu items prompted manufacturers to design sandwich presses that could accommodate a wider variety of ingredients. Presses with larger openings allowed for the inclusion of more substantial fillings, while some models even came with attachments for making paninis and other specialty sandwiches.

The 21st century has seen an even greater emphasis on innovation and customization. Modern sandwich presses often come with digital interfaces that provide precise temperature control and timer settings. Some models are even programmable, allowing chefs to save their favorite recipes and cooking profiles for quick access. Additionally, the introduction of removable, dishwasher-safe parts has made cleaning and sanitizing the presses much more convenient.

As the foodservice industry continues to evolve, so too will the commercial sandwich press. We can expect to see further advancements in technology, such as the integration of smart features that allow for remote monitoring and control. The future of the sandwich press may even include AI-driven recommendations for cooking times and temperatures based on the type of bread and fillings being used.

In summary, the evolution of the commercial sandwich press has been driven by the need for efficiency, consistency, and customization. From the cast-iron cookware of yesteryear to the high-tech appliances of today, the sandwich press has become an indispensable tool in the professional kitchen. Its journey from a simple kitchen gadget to a sophisticated piece of equipment is a testament to the industry’s commitment to innovation and excellence.

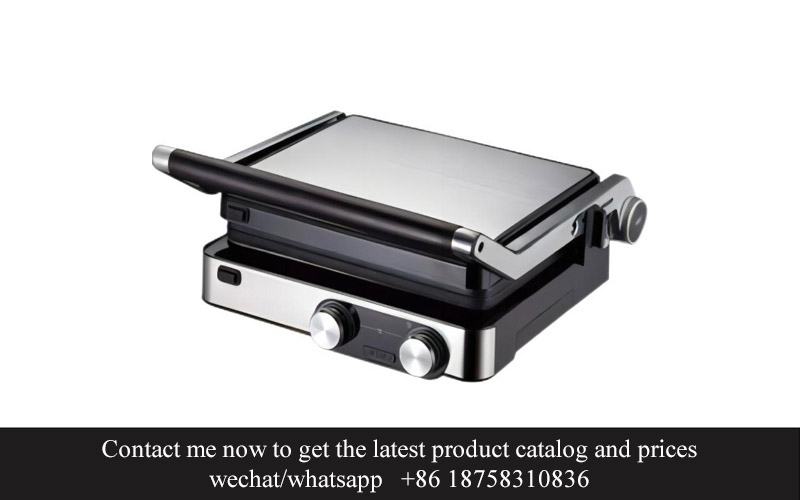

An NSF approved commercial sandwich press is not just a piece of kitchen equipment; it’s a testament to quality and safety. These presses have several key features that set them apart and make them a staple in the commercial foodservice industry.

Hygienic Construction: The cornerstone of any NSF approved sandwich press is its hygienic design. The materials used are non-reactive and resistant to corrosion, ensuring that they won’t leach harmful substances into the food. The surfaces are smooth, with no crevices where bacteria can hide, making them easy to clean and maintain.

Even Heat Distribution: Consistent cooking temperatures are crucial for the quality of a sandwich. NSF approved presses are engineered with precision heating elements that ensure the heat is distributed evenly across the entire surface of the press. This means every sandwich comes out perfectly toasted, with a golden-brown crust and a tender interior.

Temperature Control: With adjustable temperature settings, an NSF approved commercial sandwich press allows operators to achieve the perfect level of doneness for different types of bread and fillings. Whether you’re making a classic grilled cheese or a gourmet panini, the precise temperature control ensures consistency and customer satisfaction.

Efficient Heat Recovery: These presses are designed to minimize heat loss during the cooking process. They often feature insulated walls and lids, which not only conserve energy but also reduce cooking times. This efficiency is a significant cost-saving feature for busy kitchens.

Easy-to-Use Interface: The control panel on an NSF approved sandwich press is straightforward and user-friendly. It typically includes easy-to-read digital displays and intuitive controls, allowing staff to quickly adjust settings without the need for extensive training.

Safety Features: Safety is paramount in commercial kitchens, and NSF approved presses come equipped with a range of safety features. These may include automatic shut-off mechanisms to prevent overheating, protective covers to prevent accidental contact with hot surfaces, and durable materials that can withstand high temperatures and frequent use.

Robust Build Quality: These presses are built to last. They are constructed with heavy-duty steel frames and reinforced components that can withstand the rigors of a busy kitchen environment. The robust build ensures that the press will maintain its performance and appearance over many years of use.

Versatility: An NSF approved commercial sandwich press is not just for sandwiches. Many models are versatile enough to toast bagels, pizzas, or even small batches of cookies. This versatility allows for a wider menu and the potential to increase sales.

Size and Portability: While some models are designed for countertop use, others are designed to be floor-standing units. This range of sizes ensures that there is an appropriate press for every kitchen layout. Additionally, some models are designed to be more portable, with casters and handles for easy movement around the kitchen.

Certifications and Compliance: The NSF approval itself is a significant feature. It means that the sandwich press has been rigorously tested and meets stringent health and safety standards. This certification is a mark of quality that can reassure customers and regulatory inspectors alike.

Warranty and Support: A good manufacturer of NSF approved sandwich presses will offer a comprehensive warranty and excellent customer support. This means that if any issues arise, the company is committed to resolving them promptly, ensuring minimal downtime for the kitchen.

Energy Efficiency: As sustainability becomes increasingly important, energy-efficient appliances are a must. NSF approved presses are designed to minimize energy consumption, which can lead to significant savings on utility bills over time.

In summary, the key features of an NSF approved commercial sandwich press are what make it an essential tool for any foodservice establishment. From its hygienic design and precise temperature control to its safety features and versatility, these presses are designed to enhance the quality of food preparation and ensure a safe and efficient kitchen operation.

In the competitive world of food service, the choice of equipment can make or break a business. Opting for NSF (National Sanitation Foundation) approved commercial sandwich presses is a strategic decision that speaks volumes about your commitment to quality and safety. Here’s why it matters:

The NSF certification is not just a stamp of approval; it’s a testament to a product’s adherence to rigorous health and safety standards. For a commercial sandwich press, this means it has been tested and proven to maintain cleanliness, prevent cross-contamination, and ensure consistent performance over time.

Ensuring Food Safety is ParamountIn the realm of foodservice, safety is non-negotiable. An NSF approved sandwich press is designed with safety in mind, featuring materials and construction that minimize the risk of bacteria growth and contamination. The non-porous surfaces are easy to clean, reducing the likelihood of food particles harboring harmful microorganisms.

Compliance with Health Regulations is EssentialHealth codes and regulations are strict, and failing to comply can lead to fines, closures, and a tarnished reputation. By choosing an NSF approved press, you’re not just meeting the minimum standards; you’re exceeding them. This compliance is a safeguard against legal issues and a peace of mind for both your business and your customers.

Building Trust with Customers is PricelessCustomers seek out establishments that prioritize their health and well-being. An NSF approved sandwich press sends a clear message that you take food safety seriously. This trust can be a significant differentiator in a crowded market, as customers are more likely to return to a place that has earned their confidence.

Quality and Durability are KeyThe certification process also evaluates the durability of the sandwich press. This means that the product is built to last, with high-quality components that withstand the demands of a busy kitchen. A durable press means fewer breakdowns, less downtime, and a better return on investment.

Consistency in Performance is Non-NegotiableIn the foodservice industry, consistency is king. An NSF approved sandwich press ensures that every sandwich is cooked to the same high standard, every time. This consistency not only satisfies customers but also maintains the integrity of your brand.

Innovation and Energy Efficiency are at the CoreAs the industry evolves, so do the features of commercial sandwich presses. Many NSF approved models now come with innovative features like adjustable heat settings and energy-saving modes. These advancements not only enhance performance but also contribute to a more sustainable and cost-effective operation.

Investing in the Right Technology is a Strategic MoveThe right sandwich press can be a game-changer for your business. It can streamline your operations, improve efficiency, and even add value to your menu. By choosing an NSF approved model, you’re making a strategic investment that can pay off in the long run.

Customer Satisfaction and Employee MoraleA reliable and safe work environment is crucial for both customers and employees. An NSF approved sandwich press contributes to a positive dining experience, which in turn boosts customer satisfaction. For your staff, knowing they’re working with equipment that meets the highest safety standards can improve morale and job satisfaction.

In conclusion, choosing an NSF approved commercial sandwich press for your business is a multifaceted decision that touches on safety, compliance, trust, quality, and innovation. It’s an investment in the future of your business, one that can lead to increased customer loyalty, a stronger brand, and a more profitable operation.

The demand for high-quality, reliable sandwich presses has seen a surge in the commercial kitchen industry. When it comes to choosing the best sandwich presses for your business, opting for those with NSF approval can make all the difference. Here’s a look at some of the top brands and models that have earned this prestigious certification.

Brand A’s Professional Series is renowned for its durability and precision. Their sandwich presses are designed with commercial kitchens in mind, featuring heavy-duty construction and consistent heat distribution. Key features include:

For businesses with space constraints, Brand B offers a compact yet powerful commercial sandwich press. Despite its smaller size, it doesn’t compromise on performance:

Brand C’s Pro Model is a versatile choice for any kitchen. It’s designed to handle a variety of sandwich sizes and types, making it a favorite among foodservice operators:

For high-volume operations, Brand D provides a robust industrial sandwich press that can withstand constant use:

Brand E is committed to sustainability and has developed an eco-friendly sandwich press that doesn’t skimp on performance:

Each of these top brands offers sandwich presses that have met the stringent criteria set by NSF International. These presses not only provide consistent results but also offer peace of mind with their certification, ensuring that your business is in compliance with food safety standards. When selecting a sandwich press for your commercial kitchen, consider these brands and models for their reliability, versatility, and commitment to quality.

The art of crafting the perfect sandwich can elevate your culinary game, and with a new NSF-approved sandwich press, you’re well on your way to mastering this tasty craft. Here’s how to make the most of your new gadget and serve up sandwiches that are not just good, but exceptional.

Start with the right bread; the foundation of a great sandwich. Opt for thick, sturdy slices that can stand up to the heat and pressure of the press. Artisan breads, ciabatta, or even sourdough can offer a delightful contrast in texture and flavor. If you’re using a whole loaf, pre-slice your bread into even, uniform pieces for consistent cooking.

Prepare your fillings thoughtfully. The best sandwiches are a balance of flavors and textures. Think about including ingredients like crisp lettuce, ripe tomatoes, melted cheese, and a zesty sauce. If you’re making a meat sandwich, choose a high-quality meat that’s been seasoned well. Don’t overdo it with the condiments; a little goes a long way to enhance, not overpower, the flavors.

Ensure your press is preheated according to the manufacturer’s instructions. This step is crucial for achieving that perfect golden-brown crust and melting any cheese. The heat should be just right so that the bread browns beautifully without burning. If you’re using a double-sided press, it will have a temperature gauge or indicator lights to let you know when it’s ready.

Place your bread slices into the press, making sure they’re evenly spaced and not overlapping. The even distribution is key to even cooking. Add your fillings, starting with the wetter ingredients like sauces and lettuce, as they can prevent the bread from burning. If you’re adding cheese, do it now, as it will melt under the heat.

Once the press is closed, time is your ally. Most commercial sandwich presses have a short cooking time, often between 1 and 2 minutes. The sandwich should sizzle slightly and the bread should appear toasted and golden. If the top slice of bread is getting too dark before the bottom is done, lift the press and rotate the sandwich for more even cooking.

Don’t rush the process; give the press time to work its magic. As the sandwich cooks, you’ll hear a satisfying sizzle and the aroma of toasted bread filling the air. The fillings will meld together, and the cheese will melt into a creamy, gooey texture.

When the cooking time is up, carefully open the press and take out your sandwich. The exterior should be crisp, the interior tender, and the cheese gooey. If you find that the bread is not quite toasted to your liking, you can pop the sandwich back into the press for an additional 30 seconds or so.

Now, for that final touch. Serve your sandwich hot, as the warmth can enhance the flavors and textures. If you have any additional garnishes, like a spritz of lemon juice or a sprinkle of herbs, now is the time to add them. Presentation matters, so think about how you can make your sandwich look as appetizing as it tastes.

Remember, practice makes perfect. With time, you’ll learn the perfect amount of pressure to apply, the ideal cooking time, and the best way to stack your fillings for the most delicious outcome. And don’t be afraid to experiment with different combinations; sometimes the most memorable sandwiches are born from unexpected pairings. Enjoy the process and the delightful results of your culinary creativity with your new NSF-approved sandwich press.

Maintaining your NSF-approved commercial sandwich press is crucial for ensuring it remains a reliable and efficient tool in your kitchen. Here are some essential tips to keep your press in top condition:

Keep it Clean RegularlyRegular cleaning not only prevents the buildup of grime and residue but also helps maintain the hygiene standards that are so important in a commercial kitchen. After each use, wipe down the press with a damp cloth to remove any spills or crumbs. For a deeper clean, use a non-abrasive cleaner designed for kitchen equipment. Avoid using harsh chemicals that could damage the surface or the materials inside the press.

Check the Seals and GasketsSeals and gaskets are the components that keep your sandwich press tight and prevent leaks. Over time, these parts can wear out or become brittle, affecting the performance of your press. Inspect them regularly for signs of damage or wear. If you notice any issues, replace them promptly to ensure a proper seal and maintain even pressure distribution.

Lubricate Moving PartsJust like any mechanical device, your sandwich press has moving parts that need lubrication to function smoothly. Use a food-grade lubricant to apply to the hinges, hinges, and any other moving components. Be sure to follow the manufacturer’s recommendations for the type and frequency of lubrication.

Avoid OverheatingWhile a hot sandwich press is essential for achieving the perfect toasted crust, overheating can lead to damage and reduced longevity. Keep an eye on the temperature gauge if your press is equipped with one. If it’s not, use a meat thermometer to check the temperature of the press. Never exceed the recommended maximum temperature to prevent warping or melting of the press’s materials.

Store ProperlyWhen not in use, store your sandwich press in a cool, dry place. This helps prevent rust and ensures that the press is ready to use when you need it. If your press is designed to be stored vertically, do so to prevent any potential damage to the hinges or other components.

Monitor the PressureThe pressure mechanism is a key feature of a commercial sandwich press. It’s what ensures your sandwiches are uniformly toasted. Over time, the pressure can vary due to wear and tear. Regularly check the pressure and adjust it if necessary, according to the manufacturer’s instructions. This will help maintain the quality of your sandwiches and prevent any inconsistencies.

Replace Burners and ElementsIf your sandwich press has an electric heating element, it’s important to replace it when it starts to fail. A failing burner or element can lead to uneven heating and potentially pose a safety hazard. Keep a spare on hand or schedule regular maintenance checks to ensure your press is always in good working order.

Avoid Using on Hard or Uneven SurfacesPlacing your sandwich press on a hard or uneven surface can lead to misalignment and damage over time. Always use the provided stand or a flat, sturdy surface to place your press. This helps maintain the integrity of the press and ensures it operates correctly.

Use the Right BreadThe type of bread you use can impact how your sandwich press performs. Opt for bread that is suitable for pressing without becoming soggy or falling apart. Dense, crusty breads often work best, as they can withstand the heat and pressure without becoming too soft.

Remember, a well-maintained NSF-approved commercial sandwich press is an investment in the quality of your sandwiches and the efficiency of your kitchen. By following these maintenance tips, you can ensure your press serves you well for years to come.

Investing in an NSF approved commercial sandwich press is not just a purchase—it’s a strategic move for your business. Here are some final thoughts to ponder:

The longevity of your sandwich press is crucial. It’s not just about the initial cost; it’s about the value it brings over time. A well-maintained press can be the backbone of your sandwich-making operation, ensuring consistent quality and efficiency.

Imagine the convenience of having a reliable sandwich press that has been a part of your daily operations for years. It’s a testament to the durability and craftsmanship of the appliance. And let’s not forget the cost-effectiveness—replacing a press frequently is not only expensive but also disruptive to your workflow.

In the world of commercial kitchens, where time is money, the efficiency of your equipment cannot be overstated. An NSF approved sandwich press is designed to save you time without compromising on quality. It’s engineered to quickly and evenly cook your sandwiches, allowing you to serve more customers in less time.

Think about the reputation your business builds with such a reliable tool. Consistency in taste and presentation is key to customer satisfaction and loyalty. An NSF approved press can help you achieve that consistency, which is why it’s often a favorite among chefs and restaurant owners alike.

The sustainability angle is also compelling. By investing in a high-quality sandwich press, you’re making a long-term commitment to reducing waste. You’re less likely to need frequent replacements, which means fewer appliances ending up in landfills. It’s a small step for your business, but a big leap for the environment.

Innovation in design and technology has made sandwich presses more versatile than ever. Today’s models come with features like adjustable heat settings, non-stick surfaces, and removable plates for easy cleaning. These innovations not only enhance the user experience but also contribute to the press’s overall longevity.

The bottom line is that when you invest in an NSF approved commercial sandwich press, you’re making a sound business decision. It’s an investment that can pay dividends in the form of customer satisfaction, operational efficiency, and environmental responsibility.

So, as you weigh the benefits of a high-quality sandwich press, consider the following:

Remember, the sandwich press is more than just a piece of equipment—it’s an extension of your brand. It’s a symbol of the quality and care you put into every meal you serve. Investing in an NSF approved model is investing in the future of your business.