Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving world of kitchen appliances, the industrial panini press has emerged as a game-changer, blending innovation with the classic charm of a cherished culinary staple. As we delve into the world of these high-powered presses, it’s clear that their time has come. Join us as we explore the rise of the industrial panini press and its growing influence on both home chefs and the broader kitchen appliances market.

The industrial panini press has quietly but steadily risen to prominence in the European and American kitchen appliances industry. Once a niche item found only in professional kitchens, this versatile cooking tool has now found its way into the hearts and homes of culinary enthusiasts and everyday cooks alike. The surge in popularity can be attributed to a combination of factors that have converged to make the industrial panini press a must-have for any kitchen.

The demand for quick, convenient, and delicious meals has never been higher. With the fast-paced lives of modern consumers, the ability to create a gourmet sandwich in minutes has become a highly sought-after feature. Industrial panini presses have capitalized on this trend by offering a solution that is both practical and satisfying.

The rise of the industrial panini press is also a testament to the growing interest in home cooking and the DIY movement. As more people seek to take control of their food and avoid processed meals, the allure of a high-quality panini press that can produce restaurant-quality sandwiches has become irresistible. These presses have become a symbol of culinary empowerment, allowing home cooks to experiment with different ingredients and techniques without the need for extensive cooking skills.

Furthermore, the industrial panini press has been embraced by the foodservice industry. Restaurants and cafes are always looking for ways to offer unique menu items that set them apart from the competition. The ability to serve up perfectly toasted paninis with a variety of fillings has become a popular choice, leading to a significant increase in demand for commercial-grade panini presses.

The design of the industrial panini press has also played a crucial role in its rise. Modern presses come with features that make them more user-friendly and efficient than ever before. From adjustable heat settings to non-stick surfaces that ensure easy release of the sandwich, these devices are designed to enhance the cooking experience and make it as enjoyable as possible.

Another factor contributing to the popularity of industrial panini presses is the diverse range of materials used in their construction. From traditional metals to innovative materials like ceramic, these presses offer a variety of options that cater to different tastes and preferences. The use of high-quality materials not only improves the performance of the press but also extends its lifespan, making it a worthwhile investment for both home and commercial users.

The rise of the industrial panini press has also been fueled by the power of social media and online influencers. As these platforms have become more influential in shaping consumer trends, the exposure of panini presses through cooking videos, recipes, and kitchen makeovers has generated significant buzz. The ability to share visually appealing and appetizing panini creations has helped to spread the word about the versatility and convenience of these appliances.

In addition to social media, the rise of food blogs and cooking forums has also played a role in popularizing the industrial panini press. These platforms have provided a space for home cooks to share their experiences, tips, and favorite recipes, often featuring the panini press as a key component in their culinary adventures. This word-of-mouth marketing has been instrumental in building a loyal following for these presses.

The market for industrial panini presses has also been bolstered by the increasing awareness of health and wellness. As consumers become more conscious of what they are putting into their bodies, the appeal of a sandwich that can be customized with fresh, whole-food ingredients has grown. The industrial panini press allows for a level of control over ingredients that is often lacking in pre-packaged or fast-food options.

Lastly, the rise of the industrial panini press can be seen as a reflection of the changing landscape of the kitchen appliances industry. As manufacturers continue to innovate and adapt to the needs of consumers, the industrial panini press stands as a prime example of how technology and design can come together to create a product that is both functional and exciting.

In conclusion, the rise of the industrial panini press is a multifaceted phenomenon that has been driven by a combination of consumer demand, technological advancements, and the power of social media. As the market for these presses continues to grow, it’s clear that they are here to stay, becoming an integral part of the modern kitchen.

In the competitive world of kitchen appliances, the industrial panini press has emerged as a true standout with its innovative features. From the sleek design to the cutting-edge technology, here’s a closer look at what truly sets it apart:

Its robust build and durability are unparalleled. Crafted from high-grade stainless steel, these industrial presses are not just designed for frequent use but for heavy-duty tasks in busy commercial kitchens. The thick construction ensures even heat distribution, minimizing the risk of damage over time.

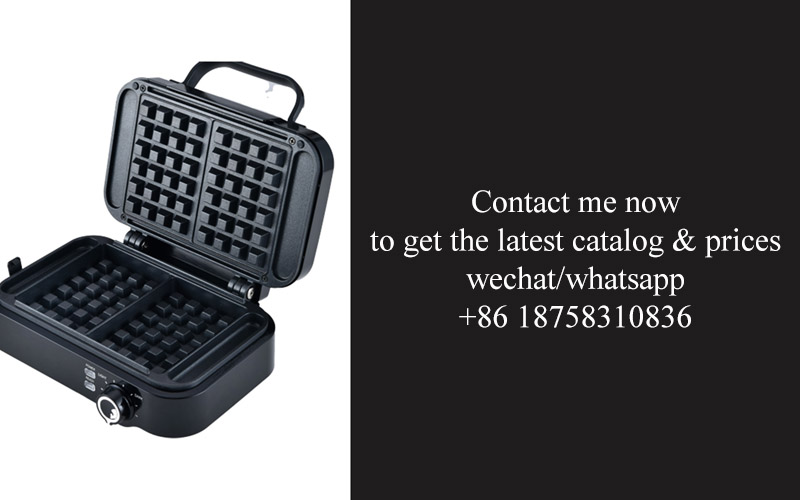

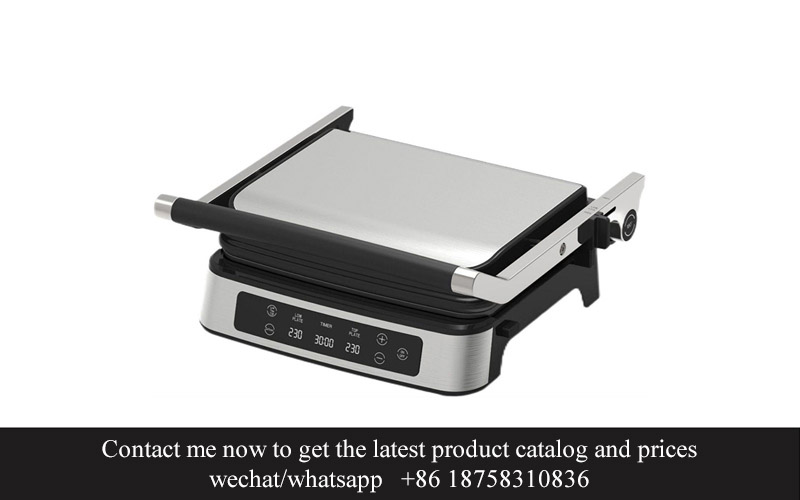

The precision controls are a game-changer. Many industrial panini presses come equipped with adjustable temperature settings, allowing chefs to perfect the perfect sandwich, burger, or flatbread to their desired crispness. Some models even offer digital readouts, ensuring accurate and consistent cooking every time.

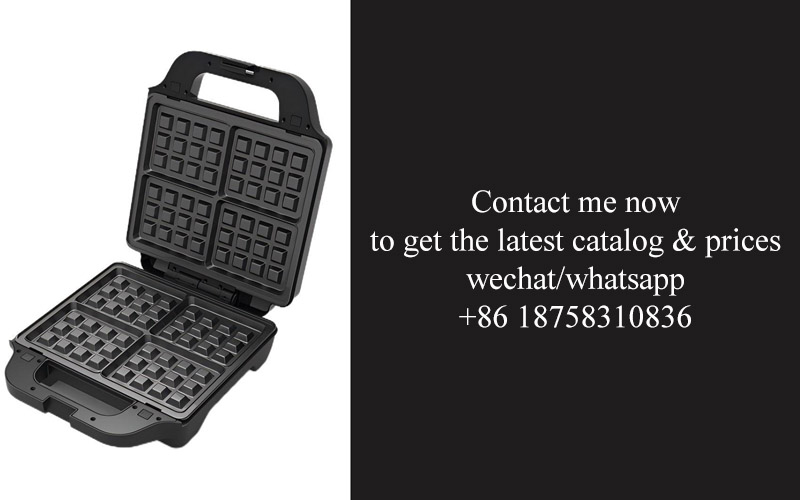

One of the most remarkable features is the variable cooking surface. Whether you’re making classic paninis, wraps, or even small pizzas, the wide and flat cooking area adapts to a variety of recipes. This versatility is a must-have for kitchens that serve a diverse menu.

Safety features are top-notch. With features like automatic shut-off, overheating protection, and cool-touch handles, these presses not only ensure a safe working environment but also peace of mind for kitchen staff and customers. The presence of non-slip feet and stable legs adds an extra layer of security against accidental tips or shifts.

Ease of cleaning is another highlight. The industrial panini press is designed with easy-to-clean surfaces in mind. Non-stick coatings make it a breeze to wipe away residue, and removable parts can be washed in a dishwasher for quick and convenient maintenance.

Efficiency is at the core of its design. The quick heating capabilities ensure that the press is ready for use in a matter of minutes, reducing downtime and increasing productivity in the kitchen. This feature is especially beneficial for high-volume operations where every second counts.

Functionality is not just limited to cooking; many industrial panini presses are equipped with features that enhance the overall user experience. For instance, foldable handles or compact designs allow for easy storage and transport when not in use. This not only saves space but also adds to the convenience of kitchen staff.

The panini press’s ability to accommodate large batches of food at once is a significant advantage. In commercial kitchens, where time is of the essence, being able to cook multiple items simultaneously can drastically cut down on prep and cooking times.

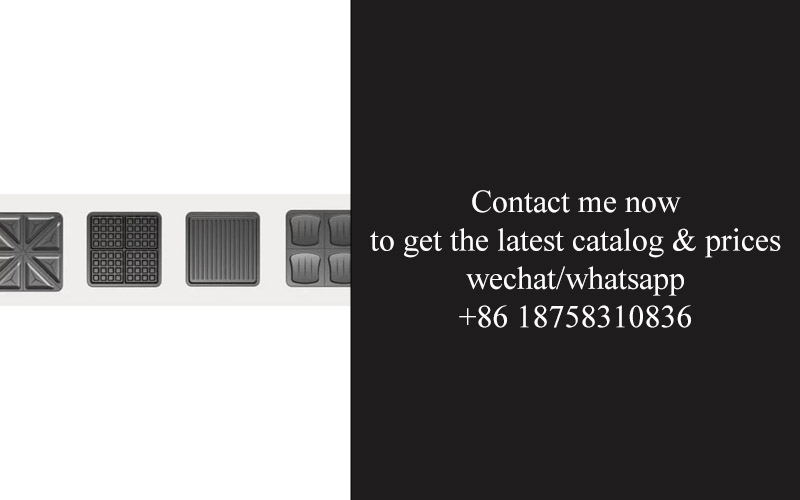

Customization is key. Some models offer interchangeable press plates, allowing chefs to experiment with different textures and styles of cooking. Whether it’s a grill pattern for that perfect char or a smooth surface for delicate items, the ability to change the press plate expands the possibilities of the industrial panini press.

Innovation in design extends to the control panel, which is user-friendly and easy to navigate. Intuitive buttons and clear LED displays ensure that operators can manage the appliance without a second thought, reducing the learning curve and improving overall efficiency.

Finally, the energy efficiency of these presses cannot be overstated. In a world increasingly aware of sustainability, industrial panini presses that heat up quickly and maintain a consistent temperature for longer periods of time are not just cost-effective but also environmentally responsible.

These innovative features have cemented the industrial panini press as a staple in modern commercial kitchens, making it an essential tool for chefs and operators who demand excellence in both form and function.

In recent years, the kitchen appliances market has witnessed a surge in innovation, and the industrial panini press has emerged as a standout product. The timing could not be more perfect for this culinary marvel to take center stage. Let’s delve into the market trends that have paved the way for the industrial panini press to become a must-have item in both European and American kitchens.

The first trend is the growing demand for convenience in everyday life. With fast-paced lifestyles and the increasing popularity of quick, on-the-go meals, consumers are seeking appliances that can deliver delicious results in minimal time. The industrial panini press is perfectly designed for this purpose, allowing users to create professional-grade sandwiches with the touch of a button.

Secondly, there’s a significant shift towards health-conscious eating habits. Many consumers are opting for homemade meals over processed foods, which often come with added preservatives and sugars. The industrial panini press enables users to control the ingredients and cooking process, making it an ideal tool for preparing wholesome, nutritious sandwiches.

Thirdly, the surge in home entertaining and social gatherings has created a need for appliances that can handle larger quantities. The industrial panini press is not just for a single sandwich; it can accommodate multiple servings at once, making it an excellent choice for hosting events or simply feeding a family.

Fourthly, the rise of gourmet food culture has sparked an interest in unique and sophisticated flavors. The industrial panini press offers a variety of functionalities, such as adjustable heat settings and various press plates, allowing for experimentation with different toppings and cooking styles. This versatility caters to the desires of food enthusiasts who are always on the lookout for the next big taste.

Fifthly, there’s a growing trend of cooking shows and reality TV that have inspired a new generation of home chefs. These programs often showcase the art of cooking, and the industrial panini press fits perfectly into this narrative. Its ability to create visually appealing and mouth-watering dishes is a huge draw for aspiring chefs and culinary enthusiasts alike.

Sixthly, the industrial panini press is an excellent addition to commercial kitchens, particularly in cafes, delis, and food trucks. These establishments are always looking for ways to streamline their operations while offering unique menu items. The industrial panini press can quickly and efficiently produce a variety of sandwiches, contributing to increased productivity and customer satisfaction.

Seventhly, there’s a significant focus on sustainability in today’s market. With the environmental impact of single-use plastics becoming more evident, consumers are seeking more sustainable alternatives. The industrial panini press promotes the use of reusable sandwich wraps and plates, reducing waste and aligning with the eco-friendly ethos of many consumers.

Eighthly, the rise of online shopping has made it easier than ever for consumers to purchase new kitchen appliances. The convenience of online shopping combined with the high demand for home cooking equipment has created a favorable environment for the industrial panini press to thrive.

Ninthly, the industrial panini press market is currently experiencing rapid growth due to the increasing popularity of street food and food trucks. These mobile food vendors are always looking for ways to differentiate themselves and offer unique menu items. The industrial panini press provides them with the opportunity to create gourmet sandwiches that stand out from the competition.

Lastly, the industrial panini press is also benefitting from the global trend of fusion cuisine. Chefs are blending flavors and techniques from different cultures, and the industrial panini press can be used to experiment with a wide range of ingredients and cooking methods, allowing for the creation of innovative and exciting fusion sandwiches.

In conclusion, the market trends currently in play have created a perfect storm for the industrial panini press. Its convenience, health benefits, versatility, and ability to cater to the latest culinary trends have positioned it as a key player in the kitchen appliances market. As these trends continue to evolve, the industrial panini press is poised to become an indispensable tool in the modern kitchen.

The culinary landscape is continually evolving, and home chefs are at the forefront of this transformation. They’re not just cooking meals; they’re crafting culinary experiences. Here’s a look into what these passionate cooks are seeking in their kitchen appliances, with a particular focus on industrial panini presses.

Home chefs are increasingly looking for appliances that not only streamline their cooking process but also add a touch of professional flair to their home kitchens. The demand for industrial-grade appliances that can deliver restaurant-quality results has surged, and the industrial panini press is at the heart of this trend.

One of the key features home chefs are seeking is versatility. No longer are they satisfied with a single-purpose appliance. The industrial panini press is designed to cater to a variety of cooking needs. It can sear, grill, toast, and flatten ingredients with ease, making it a multitasking marvel in the kitchen. From making sandwiches to grilling vegetables or even creating flatbreads, the possibilities are endless.

Quality and durability are also paramount in the minds of home chefs. They want appliances that can withstand the test of time and repeated use. Industrial panini presses are built to handle the rigors of a busy kitchen. With their sturdy construction and robust design, these presses are a testament to the strength and reliability that home chefs require.

Ease of use is another factor that can’t be overlooked. Even with all the bells and whistles, an appliance is only as good as its usability. The latest industrial panini presses are designed with intuitive interfaces, easy-to-read controls, and simple cleaning processes. Home chefs appreciate the fact that they can quickly and efficiently prepare their meals without unnecessary complications.

Sustainability is a growing concern among consumers, and home chefs are no exception. They are drawn to appliances that are energy-efficient and eco-friendly. Industrial panini presses often feature non-stick surfaces that reduce the need for oil, making them healthier options for cooking. Additionally, the efficient heating elements ensure that energy is used effectively, minimizing waste.

Personalization is also a key driver in the appliance market. Home chefs want to be able to make their own mark on their dishes. Industrial panini presses come with a variety of heat settings and temperature controls, allowing users to experiment with different cooking techniques and achieve the perfect level of crispness or tenderness. This customization appeals to the creative spirit of the home chef.

The rise of social media and online cooking communities has also influenced what home chefs are looking for. They want to be able to showcase their culinary skills to friends, family, and followers. Industrial panini presses with features like LED lights or digital temperature displays not only help achieve perfect results but also provide a visually appealing factor that can be captured on camera and shared online.

Another aspect that has gained traction is the health factor. With a focus on clean eating and reducing processed foods, home chefs are seeking appliances that can help them create wholesome, homemade meals. The industrial panini press allows them to incorporate fresh, whole ingredients into their sandwiches and wraps, making them a health-conscious choice.

Moreover, the convenience factor cannot be underestimated. Home chefs lead busy lives and are always on the lookout for appliances that can save time without compromising on quality. The ability to cook multiple ingredients simultaneously or quickly reheat leftovers makes the industrial panini press an invaluable addition to any kitchen.

Lastly, the aesthetic appeal of the appliance is often a deciding factor. Home chefs not only want their appliances to function well but also to look good in their kitchen. Modern industrial panini presses come in sleek designs that complement contemporary kitchen aesthetics, adding a touch of sophistication to the cooking space.

In conclusion, the preferences of home chefs in the kitchen appliances market are multifaceted. They are looking for versatile, durable, user-friendly, sustainable, personalized, visually appealing, health-conscious, convenient, and stylish appliances. The industrial panini press checks all these boxes, making it an ideal choice for the modern home chef who values quality, creativity, and convenience in their culinary endeavors.

Industrial panini presses have quietly been reshaping the culinary landscape, bringing a new level of efficiency and versatility to commercial kitchens. From high-volume restaurants to cafes and delis, these robust appliances are not just a trend; they’re a game-changer. Let’s delve into the ways in which industrial panini presses are revolutionizing the industry.

The ability to toast, grill, and flatten ingredients simultaneously makes these presses a multitasking marvel. They can handle everything from sandwiches to wraps, pizza, and even burgers, all with minimal effort and maximum flavor. This dual-purpose functionality is particularly valuable in kitchens where space is at a premium and time is of the essence.

Moreover, industrial panini presses are engineered for speed and durability. The high-quality materials and robust construction ensure that they can withstand the rigors of a busy kitchen environment. Their consistent heating capabilities guarantee uniform toasting and grilling, which is crucial for maintaining product quality and customer satisfaction.

The impact of these presses extends beyond just the speed and efficiency they offer. They also contribute to the overall experience for both chefs and customers. Chefs can now focus on the finer aspects of cooking, such as flavor profiles and presentation, knowing that the panini press will deliver the perfect texture and crispiness. For customers, this translates to a quicker dining experience with no compromise on taste or quality.

Another notable change brought about by industrial panini presses is the increase in menu variety. With the ability to cook a wide array of foods, restaurants can now offer a more diverse selection of items without the need for additional cooking equipment. This not only appeals to customers looking for unique dining experiences but also allows businesses to cater to dietary preferences and restrictions more effectively.

In terms of sustainability, industrial panini presses are also making waves. Their energy-efficient design means they consume less power while still providing top-notch performance. This not only helps reduce operating costs for restaurants but also aligns with the growing demand for eco-friendly practices in the food service industry.

The technology within these presses is also advancing, with many now featuring non-stick surfaces that make cleaning a breeze. This is particularly important in busy kitchens where maintaining a clean and hygienic environment is critical to food safety.

From a labor perspective, the ease of use of industrial panini presses cannot be overstated. With intuitive controls and user-friendly designs, they require minimal training for staff, which can be a significant cost-saver for businesses. Additionally, the quickness of these presses can help reduce the need for additional staff during peak hours, further cutting down on labor expenses.

Furthermore, the rise of the food truck and mobile catering sector has also benefited from industrial panini presses. These compact, portable units are perfect for on-the-go operations that need to serve large numbers of customers efficiently and effectively. The flexibility they offer in terms of menu options has opened up new avenues for entrepreneurs in the food industry.

In the realm of innovation, manufacturers have started to integrate smart technology into these presses. Features like digital temperature controls, programmable settings, and even connectivity to kitchen management systems are becoming increasingly common. This integration not only enhances the functionality of the press but also integrates it seamlessly into the modern kitchen ecosystem.

The cultural shift towards healthier eating habits has also played a role in the popularity of industrial panini presses. The versatility of these machines allows chefs to create lighter, healthier sandwiches by using whole grains, lean proteins, and fresh vegetables, all while ensuring a satisfying texture and taste.

In conclusion, the introduction of industrial panini presses has had a profound impact on the food service industry. They have transformed the way dishes are prepared, expanded menu possibilities, and improved efficiency and sustainability. As the demand for high-quality, fast service continues to grow, these presses are well-positioned to be a cornerstone in the commercial kitchen of the future.

In the culinary world, the demand for innovative cooking tools has surged, and technological advancements are at the forefront of this surge. The integration of smart features, enhanced efficiency, and ergonomic designs has transformed the landscape of kitchen appliances, with industrial panini presses leading the charge. Let’s delve into the key technological advancements that are driving the demand for these versatile machines.

The integration of smart technology has revolutionized the way industrial panini presses operate. With touch-screen interfaces, these presses offer a user-friendly experience, allowing chefs to adjust settings with ease. Features like preheat notifications, precise temperature control, and countdown timers have become standard, ensuring consistent and professional-quality results every time.

Efficiency is another critical factor in the rising demand for industrial panini presses. Modern appliances are designed with energy-saving mechanisms that reduce power consumption without compromising performance. From rapid heat-up times to even heating across the entire surface, these presses are not just faster but also more cost-effective to run. The energy-efficient design is a significant draw for businesses aiming to lower their operational costs.

Ergonomics plays a vital role in the design of industrial panini presses. The latest models come with non-slip bases, ensuring stability even during intense cooking sessions. Handles and control panels are thoughtfully placed for easy access and manipulation, reducing the risk of fatigue and improving the overall cooking experience. These ergonomic features make it easier for chefs to focus on their culinary creations rather than dealing with the equipment.

The inclusion of various cooking modes has broadened the appeal of industrial panini presses. From traditional pressurized cooking to grilling, searing, and even toast settings, these machines offer a versatile array of options. This versatility allows chefs to prepare a wide range of dishes, from classic paninis to gourmet sandwiches and flatbreads, enhancing their menu offerings without the need for additional equipment.

The use of high-quality materials in the construction of industrial panini presses is also a key driver of demand. Sturdy stainless steel bodies, durable non-stick surfaces, and heat-resistant glass windows ensure longevity and maintainability. These materials not only contribute to the aesthetic appeal of the presses but also their durability, making them a worthwhile investment for commercial kitchens.

Safety features have been a focal point in the development of industrial panini presses. From automatic shut-off functions to cool-touch handles, these presses are designed with safety in mind. Overheating protection and child safety locks are standard features, providing peace of mind for chefs and kitchen staff. This commitment to safety is crucial in a busy commercial kitchen environment where accidents can occur.

Innovation in the form of modular designs has also contributed to the growing popularity of industrial panini presses. Some models are now available with interchangeable cooking plates, allowing chefs to cater to different dietary preferences and cooking styles. This flexibility means that a single press can be used to prepare a variety of dishes, streamlining kitchen operations and reducing the need for additional equipment.

The integration of connectivity options has opened up new possibilities for industrial panini presses. Bluetooth and Wi-Fi compatibility allow these machines to be controlled remotely through smartphones and tablets. Chefs can program and monitor their presses from anywhere in the kitchen, optimizing their workflow and ensuring consistent results.

Lastly, the focus on sustainability has influenced the design of modern industrial panini presses. Eco-friendly materials and energy-efficient technologies are becoming more prevalent, appealing to businesses that are conscious of their environmental impact. As sustainability becomes a cornerstone of kitchen appliance innovation, it is likely to further drive the demand for these advanced machines.

In conclusion, the technological advancements in industrial panini presses are multifaceted, encompassing smart features, efficiency, ergonomics, versatility, material quality, safety, modular designs, connectivity, and sustainability. These innovations are not only enhancing the performance of these appliances but also shaping the expectations of consumers and businesses alike, leading to a surge in demand within the kitchen appliances industry.

In recent years, the shift towards sustainability and energy efficiency has become a cornerstone in the design of industrial panini presses. This focus is not just a trend but a necessity, as consumers and businesses alike are increasingly aware of the environmental impact of their choices. Let’s delve into how these factors are reshaping the design landscape of industrial panini presses.

The integration of eco-friendly materials is a significant step forward. Many manufacturers are now opting for stainless steel, which is not only durable but also recyclable, reducing the carbon footprint over the product’s lifecycle. This choice aligns with the growing demand for products that can be repurposed or recycled at the end of their service life.

Energy consumption is another critical aspect. Traditional panini presses can be quite energy-intensive, but modern designs have made strides in reducing power usage. Smart thermostats and programmable settings allow for precise control over cooking times, ensuring that the panini press only uses the energy necessary to achieve the desired result. This not only saves on energy bills but also contributes to a lower overall carbon emissions.

Innovative insulation technologies are also being embraced. High-quality insulation materials are used to keep the heat in, reducing the need for continuous heating and, subsequently, energy waste. This not only conserves energy but also extends the life of the appliance, as it operates more efficiently.

The design of the heating elements themselves has evolved to be more energy-efficient. Advanced heating systems now use ceramic or carbon-infused plates that distribute heat more evenly and quickly. This means less energy is required to reach and maintain the cooking temperature, offering a faster cooking experience while using less power.

Moreover, the inclusion of energy-saving modes or timers is becoming standard. These features allow users to set the panini press to turn off after a certain period, ensuring that energy is not wasted when the appliance is not in use. For commercial kitchens, this can represent significant cost savings over time.

In the realm of sustainability, the focus on water usage is also becoming more pronounced. Some industrial panini presses now come with features that reduce the need for water, such as steam-assisted cooking or non-stick surfaces that require less cleaning and thus less water. This is particularly important in commercial settings where water conservation is a key concern.

The modular design of industrial panini presses is also contributing to sustainability. By allowing for easy replacement of parts and components, these presses can be maintained and upgraded over their lifetime, reducing the need for frequent replacements and the waste that comes with them.

Lastly, the rise of the Internet of Things (IoT) is influencing the design of industrial panini presses. Smart appliances that can be monitored and controlled remotely not only offer convenience but also provide insights into energy usage patterns. This data can be used to optimize operations and further reduce energy consumption.

In conclusion, the integration of sustainability and energy efficiency in the design of industrial panini presses is a multifaceted approach that touches on materials, heating technology, energy-saving features, water usage, and smart design. These advancements are not only beneficial for the environment but also for the bottom line, making the industrial panini press a more attractive and responsible choice for businesses and consumers alike.

The industrial panini press has evolved far beyond the humble grill it once was. Today, it stands as a testament to technological innovation and consumer demand for convenience and quality. As we delve into the future of this versatile appliance, it’s clear that predictions and opportunities are abundant.

In the realm of the industrial panini press, the future is not just about cooking; it’s about sustainability and the ability to cater to a diverse range of culinary needs. Here’s a glimpse into what lies ahead.

The integration of smart technology is set to redefine the user experience. Imagine a panini press that not only grills but also connects to your smartphone, offering recipes, cooking tips, and even social media integration for sharing your culinary creations. This level of connectivity is not just a luxury; it’s a necessity in a world where technology and food are increasingly intertwined.

Customization is another area where the industrial panini press is poised to excel. With the ability to adjust heat settings, cooking times, and even the type of cooking surface (non-stick, cast iron, etc.), these appliances can cater to a wide array of preferences and dietary requirements. From vegan to gluten-free, the future panini press will be a kitchen hero for every type of eater.

As we move forward, the focus on sustainability will become even more pronounced. Materials used in the construction of these presses will be eco-friendly, with a strong emphasis on recyclability and energy efficiency. This shift is not just about reducing the carbon footprint; it’s about aligning with global efforts to combat climate change.

Energy efficiency is a cornerstone of the future industrial panini press. Innovations like induction heating, which allows for precise temperature control and reduces energy consumption, are likely to become standard features. These advancements will not only save on energy bills but also contribute to a greener planet.

The market for industrial panini presses is expected to expand significantly as the global population becomes more health-conscious. With a focus on quick, nutritious meals, these appliances will become a staple in kitchens worldwide. The convenience of preparing a gourmet sandwich in minutes is a powerful draw, especially for busy professionals and families.

Innovation in materials science will also play a crucial role. Lightweight, durable, and easy-to-clean materials will be the norm, making the industrial panini press a practical and attractive addition to any kitchen. The days of bulky, heavy appliances are fading into the past.

The rise of the foodie culture has opened doors for the industrial panini press to become a centerpiece in culinary demonstrations and food festivals. Chefs and culinary enthusiasts will be able to showcase their creativity with the help of these versatile appliances, leading to a surge in demand for high-end models with advanced features.

The future of the industrial panini press also hinges on the ability to adapt to new health trends. With an increasing number of consumers looking for ways to incorporate more vegetables into their diets, the press could feature integrated vegetable slicing and pressing capabilities, making it easier to create healthy, balanced meals.

As we look ahead, the potential for cross-industry collaboration is vast. The panini press could be integrated with other kitchen appliances, such as ovens or refrigerators, creating a seamless cooking experience. Imagine a kitchen where the panini press is just one part of a larger, interconnected system designed to streamline meal preparation.

In conclusion, the future of the industrial panini press is bright, filled with opportunities for innovation and growth. It’s not just an appliance; it’s a symbol of the evolving kitchen and the changing landscape of food consumption. As we embrace the predictions and opportunities that lie ahead, one thing is certain: the industrial panini press will continue to be a game-changer in the world of culinary arts.

The surge in home cooking culture has brought about a shift in the kitchen appliances market, with the industrial panini press emerging as a game-changer. As consumers seek out versatile and efficient appliances, the panini press has not only captured the hearts of home chefs but has also left its mark on the industry. Here’s a closer look at how embracing the panini press trend is reshaping the kitchen appliances market.

In recent years, there’s been a noticeable trend towards healthier eating habits and home-cooked meals. This shift has been fueled by an increased awareness of the benefits of homemade food, including better control over ingredients and portion sizes. The industrial panini press, with its ability to cook a variety of dishes in a single appliance, aligns perfectly with these values. It’s no surprise, then, that the demand for these versatile machines has been on the rise.

The convenience factor cannot be overstated. The panini press offers a quick and easy way to prepare a variety of sandwiches, from classic ham and cheese to gourmet options with avocado and pesto. For busy individuals or families, this is a significant draw. Moreover, the versatility of the press means it can also be used to cook other foods like grilled cheese, burgers, and even pizzas, making it a staple in many kitchens.

Moreover, the industrial panini press has become a symbol of culinary innovation. Its sleek design and high-tech features have set it apart from traditional sandwich makers. With adjustable heat settings, non-stick surfaces, and even models with digital controls, the industrial panini press is no longer just a simple appliance; it’s a tool that can elevate the cooking experience.

In the realm of sustainability, the industrial panini press has also found its place. As consumers become more environmentally conscious, they are seeking out products that are not only efficient but also eco-friendly. Many modern panini presses are made from recycled materials and are designed to minimize energy consumption, appealing to the eco-conscious consumer base.

The integration of smart technology in kitchen appliances has also played a role in the popularity of the industrial panini press. With features like Bluetooth connectivity and remote control options, these presses are not just for cooking; they are also part of the smart home experience. This added functionality has made them a must-have for tech-savvy consumers who want to enhance their kitchen with the latest innovations.

The impact of the industrial panini press on the industry is profound. Manufacturers have responded by expanding their product lines to include various models and styles, catering to different preferences and budgets. Retailers have also noticed the trend, with many featuring panini presses prominently in their advertising and in-store displays. This has created a ripple effect, influencing the broader kitchen appliances market to focus more on innovation and convenience.

Looking ahead, the future of the industrial panini press is bright. As the demand for versatile, efficient, and sustainable kitchen appliances continues to grow, the panini press is poised to become an even more integral part of the kitchen. Here are some predictions and opportunities that lie ahead:

Predictions:- The development of panini presses with even more advanced features, such as built-in timers, temperature control, and the ability to cook multiple sandwiches simultaneously.- An increase in the use of renewable energy sources and sustainable materials in the manufacturing process.- The integration of AI and machine learning to provide personalized cooking recommendations and maintenance alerts.

Opportunities:- Collaborations with food tech companies to create recipes and cooking guides that showcase the versatility of the panini press.- Expansion into international markets, where the convenience and efficiency of the appliance are equally valued.- The potential for the panini press to become a centerpiece in kitchen design, with sleek and modern aesthetics becoming the norm.

In conclusion, the panini press has become more than just a kitchen gadget; it’s a trendsetter that’s changing the way we think about cooking and dining. As the market continues to evolve, embracing this trend will be key for those looking to stay ahead in the competitive kitchen appliances industry. Whether it’s through innovation, sustainability, or convenience, the industrial panini press is here to stay, and it’s paving the way for a new era of culinary experiences.