Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the realm of modern living, the kitchen has evolved from a mere place for cooking to a hub of innovation and convenience. Central to this transformation are the integrated circuit boards (ICBs) that power the appliances that make our culinary experiences not just easier, but also more exciting and efficient. This article delves into the fascinating world of ICBs in kitchen appliances, exploring their impact, the latest innovations, market trends, and the challenges and opportunities that shape the future of smart kitchen technology.

The kitchen, once a humble space for basic cooking needs, has transformed into a hub of innovation and technological marvels. The evolution of kitchen appliances mirrors this transformation, from the rudimentary tools of our ancestors to the sophisticated smart devices we rely on today.

In the earliest days of human civilization, cooking was a labor-intensive task performed over open fires. The tools were simple: pots made from clay, wooden spoons, and perhaps a stone mortar and pestle for grinding grains. These primitive implements were the foundation of kitchen appliances, serving as the earliest predecessors to modern devices.

As time progressed, the Industrial Revolution brought about significant changes. Stoves and ovens began to replace open fires, offering a safer and more controlled cooking environment. Cast iron cookware became popular, providing durability and heat retention. The advent of the electric iron in the late 19th century marked the first entry of electricity into the kitchen, signaling the beginning of a new era.

The 20th century saw a surge in kitchen appliance innovation. Electric stoves and ranges replaced coal and wood-fired models, making cooking more efficient and less labor-intensive. Refrigerators, introduced in the early 20th century, revolutionized food preservation, allowing families to store perishables for longer periods.

The 1950s and 1960s were a golden age for kitchen appliance development. Appliances like dishwashers, microwaves, and automatic washing machines became standard in many homes, freeing up time for other activities. The focus shifted from efficiency to convenience, as manufacturers sought to simplify daily tasks.

The late 20th century brought about the integration of technology into kitchen appliances. Microwaves became more powerful and versatile, offering a variety of cooking functions. Ovens and cooktops started featuring programmable settings and timers, making meal preparation even more user-friendly.

The 21st century has been a period of rapid technological advancement in kitchen appliances. Smart kitchen gadgets, such as smart ovens, refrigerators with built-in cameras, and voice-activated kitchen assistants, have become increasingly common. These devices not only make cooking easier but also provide valuable data on food storage and nutrition.

The evolution of kitchen appliances has been driven by several key factors. One is the demand for convenience, as consumers seek to save time and effort in their daily routines. Another is the quest for efficiency, with appliances becoming more energy-efficient and effective at their tasks. Safety has also been a major concern, with appliances designed to minimize the risk of fires and accidents.

In recent years, sustainability has emerged as a significant factor in the design of kitchen appliances. Manufacturers are increasingly focusing on creating eco-friendly products that reduce energy consumption and waste. This shift is not only good for the environment but also for consumers who are becoming more conscious of their carbon footprints.

The integration of the internet and mobile technology has also played a pivotal role in the evolution of kitchen appliances. Smart appliances can now be controlled remotely, allowing users to monitor and adjust settings from their smartphones. This connectivity has opened up new possibilities for personalized cooking experiences and has led to the development of apps that provide recipes, meal planning, and even nutritional advice.

In conclusion, the evolution of kitchen appliances has been a testament to human ingenuity and the relentless pursuit of convenience, efficiency, and safety. From the simple pots and pans of ancient times to the smart, connected devices of today, the kitchen has become a place where technology and culinary art intersect. As we continue to innovate, the future of kitchen appliances promises to be even more exciting, offering even greater ease and enjoyment in the heart of our homes.

In the realm of modern kitchen appliances, the integration of Integrated Circuit Boards (ICBs) has become a cornerstone of innovation and efficiency. These tiny, intricate pieces of technology have transformed the way we interact with our kitchen gadgets, making them smarter, more responsive, and far more capable than their predecessors.

ICBs are the brains behind the brawn of kitchen appliances, providing the necessary processing power to handle complex tasks with ease. From the sleek, intuitive interface of a smart oven to the precise control systems in a high-end refrigerator, the presence of an ICB is often unseen but always felt.

One of the most remarkable aspects of ICBs is their ability to process vast amounts of data at incredibly high speeds. This capability is crucial in kitchen appliances that require real-time monitoring and adjustment, such as induction cooktops that can modulate heat output based on the cookware’s material and the food’s requirements. The speed and accuracy of these systems are made possible by the advanced microchips within the ICBs.

Moreover, ICBs are the heart of connectivity in kitchen appliances. They enable devices to connect to the internet, allowing users to remotely control their appliances through smartphones or smart home systems. Imagine being able to preheat your oven while still at work or to set your refrigerator to its most energy-efficient setting while on vacation. This level of convenience is made possible by the seamless integration of ICBs with wireless technology.

Energy efficiency is another area where ICBs have made a significant impact. By optimizing the power consumption of appliances, these microchips help reduce energy costs and lower the carbon footprint of homes. For instance, a refrigerator with an ICB can analyze the temperature fluctuations and adjust its cooling cycles accordingly, ensuring that it doesn’t waste energy when the room is unoccupied.

The miniaturization of ICBs has also led to the creation of more compact and aesthetically pleasing kitchen appliances. The ability to fit complex circuitry into a small space has allowed manufacturers to design sleek, modern kitchenware that blends seamlessly into contemporary kitchen aesthetics. The sleek, minimalist design of today’s kitchen appliances is, in many cases, directly attributed to the advancements in ICB technology.

In terms of safety, ICBs have played a pivotal role in enhancing the security of kitchen appliances. With built-in safeguards, these microchips can detect anomalies and prevent potential hazards, such as overloading or overheating. This not only protects the appliance from damage but also ensures the safety of the user and the surrounding environment.

The versatility of ICBs is also noteworthy. They can be tailored to suit a wide range of applications, from the simple control of a countertop blender to the intricate management of a multifunctional kitchen island. This adaptability allows for a diverse array of kitchen appliances, each designed to cater to specific user needs and preferences.

Furthermore, the integration of ICBs has paved the way for the development of smart kitchen ecosystems. These ecosystems allow for the seamless coordination of various appliances, creating a cohesive and intelligent kitchen environment. For example, a smart kitchen system can automatically adjust the lighting, temperature, and cooking settings based on the time of day and the user’s schedule, all thanks to the sophisticated ICBs that power these interconnected devices.

The future of kitchen appliances looks even brighter with the continued evolution of ICB technology. As we move towards more sustainable and energy-efficient living, ICBs will undoubtedly play a crucial role in driving these advancements. The potential for integration with other technologies, such as artificial intelligence and the Internet of Things (IoT), is vast, and the possibilities for innovation are nearly limitless.

In conclusion, the power of Integrated Circuit Boards (ICBs) in kitchen appliances cannot be overstated. They are the unsung heroes that make modern kitchens not just more convenient, but also safer, smarter, and more sustainable. As technology continues to advance, the role of ICBs in shaping the future of kitchen appliances will only grow more significant.

In the heart of the modern kitchen, the humble integrated circuit board (ICB) holds a pivotal role, much like the unseen maestro orchestrating the symphony of culinary creations. These tiny, intricate components are the backbone of the smart kitchen revolution, transforming traditional appliances into intelligent, interconnected devices. The impact of ICB factories, therefore, cannot be overstated.

ICB factories have become the crucible of innovation, where raw materials are transformed into the digital pulse of kitchen appliances. The precision and sophistication of these factories are paramount, as each ICB is a marvel of miniaturization and complexity. Let’s delve into the profound impact these factories have on our lives.

The rise of smart kitchen appliances is a direct consequence of the advancements in ICB technology. These boards are the brain behind the brawn, enabling devices to learn, adapt, and communicate. Refrigerators that track inventory, ovens that adjust cooking times based on food type, and dishwashers that optimize cleaning cycles—these are all made possible by the sophisticated algorithms embedded within ICBs.

The efficiency gains achieved through ICBs are not just confined to the appliances themselves. ICB factories have also played a crucial role in energy conservation. Smart appliances can now operate with greater precision, using less energy while maintaining peak performance. This shift towards energy-efficient technology is not just environmentally friendly but also cost-effective for consumers.

The integration of ICBs into kitchen appliances has also had a significant impact on user experience. Modern kitchens are no longer just places for cooking; they are hubs of connectivity and entertainment. ICBs enable appliances to sync with smartphones and home automation systems, allowing users to control and monitor their kitchen from anywhere. This seamless integration has redefined convenience, making smart kitchens more accessible to a broader audience.

The quality control processes within ICB factories are rigorous, ensuring that each board meets the stringent standards required for reliable performance. From the initial design to the final product, these factories adhere to a meticulous process that includes material selection, circuit design, testing, and assembly. The result is a high level of consistency that is essential for the reliability of smart kitchen appliances.

Moreover, the global nature of ICB factories has facilitated a collaborative environment where ideas from around the world converge. This has led to the development of ICBs that are not only powerful and efficient but also diverse in their applications. The interconnectivity of these factories has also fostered the growth of a robust supply chain, ensuring that components are available when and where they are needed.

The impact of ICB factories extends beyond the confines of the kitchen. The technologies developed for kitchen appliances have crossover applications in other industries. For example, the same sensors and microcontrollers used in smart refrigerators are now finding their way into medical devices, automotive systems, and even aerospace technology. This demonstrates the far-reaching implications of the work done within ICB factories.

Innovation within ICB factories is a constant pursuit. As consumer demands evolve, so too do the capabilities of kitchen appliances. ICB factories are at the forefront of this evolution, continuously pushing the boundaries of what is possible. From advancements in artificial intelligence to improvements in connectivity, the pace of innovation is rapid and relentless.

The rise of ICB factories has also had a profound effect on the economy. These facilities create jobs, support local communities, and contribute to the global market. The growth of the smart kitchen industry has spurred the development of new markets and has the potential to drive economic growth on a global scale.

In conclusion, the impact of ICB factories on the kitchen appliance industry is profound. They have transformed the way we interact with our appliances, making them more efficient, connected, and user-friendly. The work done within these factories is not just about creating smart kitchens; it’s about shaping the future of technology and its integration into our daily lives.

In the realm of kitchen appliances, the integration of cutting-edge innovations in integrated circuit boards (ICBs) has been a game-changer. These advancements have not only enhanced the functionality of everyday kitchen devices but have also paved the way for smart, connected cooking experiences. Let’s delve into some of the groundbreaking innovations shaping the future of kitchen appliances powered by ICBs.

The Miniaturization RevolutionICBs have enabled the miniaturization of components, making it possible to incorporate advanced features into compact kitchen appliances. This trend has led to the development of sleek, space-saving devices that are as powerful as their larger counterparts. For instance, compact ovens now come equipped with precision heating elements and smart sensors, thanks to ICBs, allowing for precise temperature control and reduced cooking times.

Smart Cooking AlgorithmsOne of the most significant advancements brought about by ICBs is the integration of smart cooking algorithms. These algorithms analyze user preferences, cooking habits, and even the quality of ingredients to optimize cooking processes. Appliances like smart ovens can now automatically adjust cooking times and temperatures based on the specific recipe and ingredient data, ensuring consistent results every time.

Voice Control and AI IntegrationThe integration of ICBs has also facilitated the inclusion of voice control technology in kitchen appliances. Through voice assistants like Amazon Alexa or Google Assistant, users can now control their kitchen appliances hands-free, making cooking more convenient and accessible. Additionally, AI integration has allowed appliances to learn and adapt to individual cooking styles, providing personalized recommendations for recipes and cooking methods.

Energy Efficiency and SustainabilityEnergy consumption is a significant concern in the kitchen appliance industry. ICBs have played a crucial role in enhancing energy efficiency, with devices now capable of adjusting power usage based on cooking demands. Smart refrigerators, for example, can optimize cooling cycles to reduce energy consumption while maintaining optimal food preservation. This focus on sustainability is not only cost-effective for consumers but also environmentally friendly.

Health Monitoring and Safety FeaturesWith ICBs, kitchen appliances can now incorporate health monitoring features. Smart cookware can track cooking temperatures and times, alerting users to potential foodborne illnesses. Moreover, appliances with ICBs can provide real-time feedback on the nutritional content of meals, helping consumers make healthier choices. Safety features like overheat protection and child lock mechanisms have also become standard, thanks to the precision and reliability offered by ICBs.

Connectivity and Data CollectionThe integration of ICBs has opened up possibilities for connectivity within the kitchen ecosystem. Devices can now communicate with each other, sharing data to create a seamless cooking experience. Smart kitchen systems can collect data on cooking habits and preferences, providing insights that can be used to tailor recipes, suggest improvements, and even order replacement parts or ingredients automatically.

Customization and PersonalizationICBs have also made it possible for kitchen appliances to be more customizable and personalized. Users can now select specific features, such as the number of cooking modes or the type of display, to create appliances that perfectly match their needs. This level of personalization extends to the software side as well, with manufacturers offering downloadable updates that can add new functionalities and improve overall performance.

Predictive Maintenance and DiagnosticsMaintenance is a critical aspect of appliance longevity, and ICBs have made it easier to implement predictive maintenance. Devices can now analyze their performance and predict when they might need service or replacement parts, reducing downtime and extending the life of the appliance. This proactive approach to maintenance ensures that kitchen appliances remain efficient and reliable.

In conclusion, the integration of cutting-edge innovations in ICBs for kitchen appliances has transformed the way we cook and interact with our kitchen tools. From miniaturization and smart cooking algorithms to voice control and energy efficiency, these advancements are reshaping the kitchen landscape, offering users unparalleled convenience, safety, and functionality. As technology continues to evolve, we can expect even more innovative features to emerge, further enhancing our culinary experiences.

In recent years, the kitchen appliance industry has undergone a remarkable transformation, driven by evolving market trends and shifting consumer demands. This dynamic interplay has led to a surge in innovative products and services that cater to a more sophisticated and health-conscious consumer base. Let’s delve into the key trends and demands shaping the kitchen appliances market.

The rise of smart appliances has been a game-changer, with consumers increasingly seeking convenience and connectivity. Smart refrigerators, for instance, not only keep food fresh but also offer features like remote monitoring and integration with other smart home devices. This shift towards smart technology is not just a luxury but a necessity for many, reflecting a broader trend of automation and efficiency.

Health and wellness have become central concerns for consumers, leading to a growing demand for kitchen appliances that promote healthier lifestyles. High-end brands are capitalizing on this trend by offering appliances that cater to specific dietary needs, such as gluten-free or low-carb settings on ovens and cooktops. Additionally, the popularity of sous-vide cooking, which allows for precise temperature control, has surged, driven by consumers’ desire for consistent and healthful results.

Sustainability is another major factor influencing consumer choices. Eco-friendly appliances, like those with energy-efficient ratings and sustainable materials, are becoming more prevalent. Consumers are not just looking for products that reduce their carbon footprint but also those that align with their values and contribute to a greener planet.

The kitchen is no longer just a place for cooking; it’s a hub for entertainment and socializing. As such, there’s a growing market for multifunctional appliances that can cater to these needs. For example, built-in coffee machines with customizable settings are becoming popular, as are appliances that can be controlled remotely, allowing for the preparation of meals even before the consumer arrives home.

Customization and personalization are also key drivers of consumer demand. Consumers are no longer satisfied with one-size-fits-all solutions; they want appliances that can be tailored to their specific preferences and kitchen layouts. This has led to a surge in modular kitchen appliances and customizable color options, allowing homeowners to create a kitchen that reflects their individual style.

In terms of design, sleek and modern aesthetics are in high demand. Consumers are looking for appliances that not only serve a functional purpose but also enhance the aesthetic appeal of their kitchen. The popularity of stainless steel and matte finishes is a testament to this trend, as they offer a timeless look that complements various kitchen designs.

Another significant trend is the integration of kitchen appliances with mobile devices. The ability to control and monitor appliances through smartphones and tablets has become a standard feature, offering convenience and peace of mind. Consumers appreciate the ability to adjust cooking times or preheat ovens while on the go, or to receive notifications when their meal is ready.

Finally, the rise of meal delivery services and the growing trend of home cooking have created a demand for appliances that can handle the demands of both. Consumers are looking for appliances that can efficiently manage batch cooking for meal prep, as well as those that can handle the unique requirements of sous-vide cooking or fermentation processes.

In conclusion, the kitchen appliance market is being shaped by a combination of technological advancements, health-conscious living, sustainability concerns, and the changing role of the kitchen in modern homes. Understanding these trends and demands is crucial for manufacturers and retailers looking to stay ahead in this dynamic industry.

In the realm of kitchen appliances, the collaboration between integrated circuit board (ICB) factories and appliance manufacturers has led to groundbreaking advancements. Let’s delve into a few case studies that showcase successful partnerships:

In one such collaboration, a renowned ICB factory partnered with a leading kitchen appliance brand to develop a line of smart ovens. The ICBs were designed to optimize cooking times and temperatures, ensuring that users could achieve perfect results every time. This innovative technology allowed the ovens to communicate with other smart devices in the kitchen, creating a seamless and efficient cooking experience.

The ICBs in these smart ovens were equipped with advanced processors that could analyze recipes and suggest cooking settings based on the user’s preferences. This level of personalization was made possible by the integration of machine learning algorithms within the ICBs, which continuously learned from user habits and adjusted the cooking parameters accordingly.

Another notable collaboration involved a partnership between an ICB factory and a well-known blender manufacturer. The challenge was to create a blender that could handle a wider range of ingredients and textures with precision. The ICBs developed for this project were designed to control multiple blades and motors simultaneously, ensuring that the blender could handle anything from smoothies to dough with ease.

The ICBs in this blender were also equipped with sensors that could detect the consistency of the mixture and automatically adjust the speed and power levels. This not only saved users time but also provided them with consistent results every time. The collaboration between the ICB factory and the blender manufacturer resulted in a product that was not only powerful but also user-friendly.

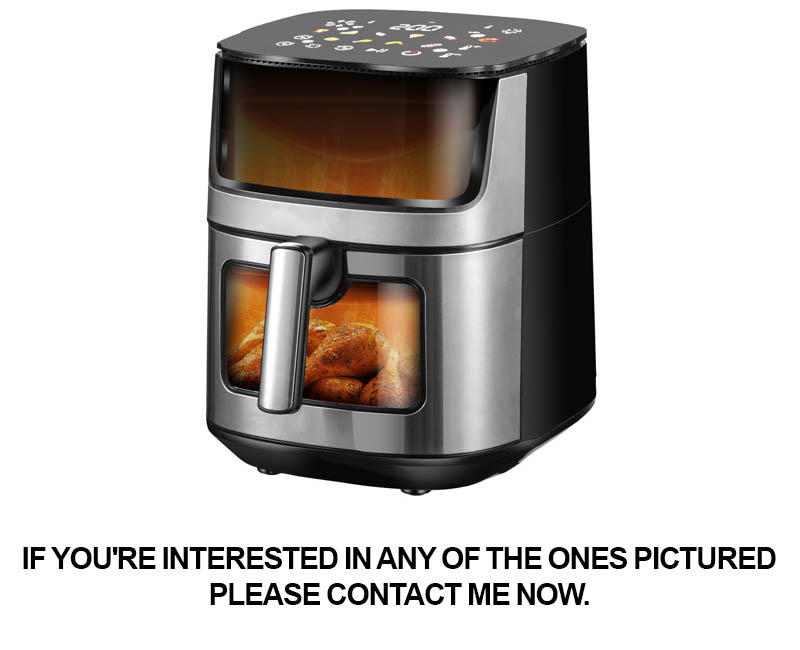

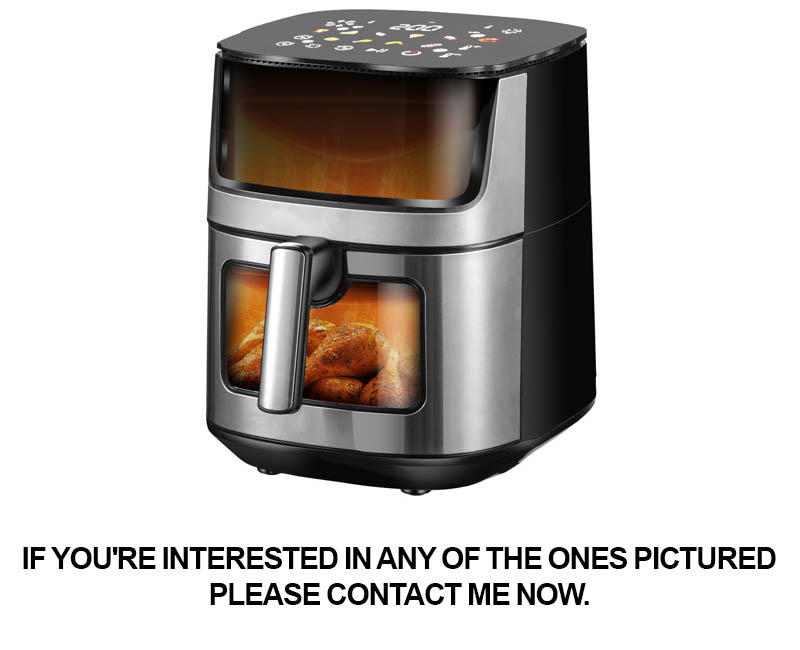

A third case study highlights the collaboration between an ICB factory and a small appliance company specializing in air fryers. The initial goal was to create an air fryer with a more precise temperature control system. The ICBs developed for this project incorporated high-resolution temperature sensors and a microcontroller that could maintain the fryer’s temperature within a narrow range, ensuring consistent cooking results.

The ICBs also included a feature that allowed the air fryer to connect to a user’s smartphone app, providing real-time monitoring and control. This innovative integration meant that users could start, stop, or adjust their cooking sessions remotely, adding a layer of convenience that was previously unavailable in the air fryer market.

In another collaboration, an ICB factory worked with a major kitchen appliance brand to develop a line of smart refrigerators. The ICBs in these refrigerators were designed to optimize energy efficiency and food freshness. They included a suite of sensors that could monitor the internal temperature, humidity, and even the quality of the food stored within.

The ICBs were also responsible for managing the refrigerator’s LED lighting system, which was designed to minimize energy consumption while providing ample illumination. Moreover, the ICBs enabled the fridge to connect to the user’s home network, allowing for remote monitoring and control. Users could receive alerts about expired items or adjust the fridge’s settings from their smartphones, making the appliance an integral part of their smart home ecosystem.

These case studies demonstrate the transformative impact of ICB factory collaborations on the kitchen appliance industry. By combining the expertise of ICB manufacturers with the product development skills of appliance companies, these partnerships have led to a new generation of smart, efficient, and user-friendly kitchen appliances. As technology continues to evolve, the potential for further innovation through these collaborations is vast, promising a future where the kitchen is not just a place for cooking, but a hub of advanced technology and seamless integration.

In the realm of smart kitchen technology, the potential for innovation is vast and ever-evolving. As we delve into the future, several key trends and advancements are poised to redefine how we interact with our kitchen appliances. Here’s a glimpse into what the future might hold:

1. Enhanced ConnectivityThe kitchen of the future will be a hub of interconnected devices, all working in harmony. Imagine a scenario where your refrigerator communicates with your oven to optimize cooking times based on the ingredients you have on hand. This level of connectivity will require sophisticated ICBs that can handle complex data exchanges and ensure seamless integration.

2. Personalized Cooking ExperiencesWith advancements in AI and machine learning, kitchen appliances will be able to learn your preferences and tailor their performance accordingly. From adjusting the flavor profile of your coffee to perfectly timing the cooking process of a complex dish, ICBs will enable a level of personalization that goes beyond the capabilities of current smart kitchen gadgets.

3. Energy Efficiency and SustainabilityEnergy consumption is a significant concern in modern homes. The future of smart kitchen technology will see a greater emphasis on energy efficiency. ICBs will play a crucial role in optimizing energy use, ensuring that appliances consume power only when necessary and in the most efficient manner possible. This could include adaptive energy management systems that adjust to the user’s habits and the environment.

4. Health and Wellness IntegrationAs health and wellness become more prevalent in consumer consciousness, kitchen appliances will be designed to support these goals. ICBs will enable features such as nutrient analysis in food processors, allergy detection in ovens, and even meal planning based on dietary restrictions. Smart scales and fitness trackers may also be integrated into kitchen appliances, providing a comprehensive approach to health and wellness.

5. Voice and Gesture ControlThe future kitchen will likely be more hands-free and interactive. ICBs will power voice assistants that can control multiple appliances simultaneously, as well as gesture recognition technology that allows users to manipulate their kitchen gadgets with simple hand movements. This will not only make cooking more convenient but also cater to users with physical limitations.

6. Modular and Upgradeable AppliancesSmart kitchen appliances of the future will be modular, allowing users to upgrade components as technology advances. ICBs will enable a plug-and-play system where new modules can be easily swapped out for improved performance or additional features. This approach will ensure that kitchen appliances remain current and functional for years to come.

7. Advanced Security MeasuresWith the increasing number of smart devices in the home, security will be a top priority. ICBs will incorporate advanced encryption and authentication protocols to protect user data and prevent unauthorized access. This will be particularly important for appliances that are connected to the internet and can be controlled remotely.

8. Environmental SensingKitchen appliances will become more attuned to their surroundings, with ICBs enabling environmental sensors that can detect changes in temperature, humidity, and even air quality. This could lead to appliances that can adjust their operation to maintain optimal conditions in the kitchen, such as automatically defrosting the freezer when temperatures drop outside.

9. Integration with Smart Home SystemsThe smart kitchen will be an integral part of the broader smart home ecosystem. ICBs will facilitate communication between kitchen appliances and other smart home devices, such as security systems, lighting, and heating. This will create a cohesive living environment where the kitchen is just one component of a harmonious and efficient home.

10. Customization and Personalization on a Grand ScaleFinally, the future of smart kitchen technology will offer levels of customization and personalization that were once only dreams. From customizable cooking modes to personalized recipe suggestions, ICBs will enable a kitchen that caters to the unique tastes and needs of each household.

In conclusion, the future of smart kitchen technology is bright and filled with possibilities. The role of ICBs in driving this evolution is undeniable, as they will be the backbone of the interconnected, efficient, and personalized kitchens of the future.

In the ever-evolving landscape of technology, the challenges and opportunities within the integrated circuit board (ICB) manufacturing sector are profound. These challenges are often met with innovative solutions that create new opportunities for growth and advancement.

The complexity of ICBs has surged with the demand for smart kitchen appliances. These devices require intricate circuitry to function seamlessly, and the industry faces the challenge of keeping up with the rapid pace of technological advancements. One such challenge is the miniaturization of components without compromising on performance or reliability.

In response, manufacturers are investing in advanced semiconductor processes that allow for smaller, more efficient ICBs. This shift not only meets the needs of smart kitchen appliances but also opens up new avenues for energy-efficient devices across various industries.

The rise of the Internet of Things (IoT) has presented a significant opportunity for ICB factories. As kitchen appliances become more interconnected, the demand for specialized ICBs that can handle data processing and communication has surged. This has led to a surge in research and development efforts aimed at creating ICBs that are not only powerful but also secure against cyber threats.

Another challenge lies in the supply chain. The global nature of the electronics industry means that disruptions can occur at any point, impacting the production of ICBs. Factories are addressing this by diversifying their supply chains and investing in local production capabilities to reduce reliance on a single source.

Opportunities arise from the need for sustainability. As consumers become more environmentally conscious, there’s a growing demand for ICBs that are manufactured with eco-friendly materials and processes. This shift not only aligns with consumer values but also presents a chance for ICB factories to innovate and lead the market in green technology.

The integration of artificial intelligence (AI) into kitchen appliances is another opportunity. ICBs are at the heart of this integration, enabling appliances to learn from user habits and adapt accordingly. This requires ICBs that can process vast amounts of data and make real-time decisions, which is a complex but highly rewarding challenge for manufacturers.

Moreover, the customization of ICBs for specific applications is becoming increasingly important. Kitchen appliances are no longer one-size-fits-all, and consumers are looking for tailored solutions that meet their unique needs. This customization requires a high degree of precision in ICB design and production, offering an opportunity for manufacturers to create specialized products that stand out in a competitive market.

The challenge of maintaining high-quality standards while scaling up production is another area where ICB factories are finding opportunities. By investing in automated and robotic assembly lines, manufacturers can achieve both efficiency and quality control. This not only reduces the risk of human error but also allows for the production of millions of ICBs without compromising on the end product’s integrity.

In the realm of quantum computing, which is poised to revolutionize the way we process information, ICB factories are at the forefront. The development of quantum ICBs could lead to kitchen appliances that are not just smart but superintelligent. While this is a long-term goal, the research and development efforts are already yielding benefits in terms of improved ICB performance and efficiency.

The challenge of integrating new technologies into existing appliances is also an opportunity. Upgradable ICBs allow manufacturers to extend the life of kitchen appliances by enabling them to incorporate the latest innovations without the need for a complete replacement. This approach not only satisfies consumer demands for the latest technology but also aligns with the circular economy principles of reducing waste.

Lastly, the opportunity to collaborate with other industries is a significant advantage for ICB factories. By working with companies in healthcare, automotive, and other sectors, manufacturers can leverage cross-industry knowledge to develop ICBs that are versatile and adaptable to a wide range of applications.

In conclusion, the challenges and opportunities in the ICB manufacturing sector for smart kitchen appliances are interconnected. By addressing the former, manufacturers are uncovering the latter, leading to a more innovative and sustainable future for the industry.

In the heart of the smart kitchen, where innovation meets convenience, the integration of advanced technologies has reshaped the way we interact with our cooking spaces. From the sleek design of induction cooktops to the voice-activated smart fridges, the evolution of kitchen appliances has been driven by the intricate and powerful work of integrated circuit board (ICB) factories. As we reflect on the journey of these factories and their collaborations, let’s delve into the essence of what makes the smart kitchen a cornerstone of modern living.

The smart kitchen has become a hub of interconnected devices, each contributing to a seamless and efficient culinary experience. ICB factories have played a pivotal role in this transformation, not just by producing the essential components, but also by fostering partnerships that push the boundaries of what’s possible. These collaborations have led to groundbreaking advancements, from energy-efficient appliances to those that can predict and prepare meals based on user preferences.

One notable example is the partnership between a leading ICB factory and a renowned appliance manufacturer. Together, they developed a line of smart ovens that utilize AI to analyze recipes and adjust cooking times and temperatures for optimal results. This fusion of hardware and software has not only simplified the cooking process but has also opened doors for personalized culinary experiences.

The market for smart kitchen appliances has seen a surge in demand, driven by both technological advancements and changing consumer habits. As people seek more efficient and convenient ways to manage their daily lives, the integration of smart technology into kitchen appliances has become a norm. Consumers now expect their kitchen devices to be not just tools but also companions that can adapt to their needs and preferences.

The rise of the smart kitchen has also been influenced by the growing awareness of sustainability and energy conservation. ICB factories have responded by producing more energy-efficient ICs that not only reduce utility bills but also minimize the environmental impact. This shift towards sustainability is not just a trend but a fundamental change in how we approach kitchen technology.

In the realm of smart kitchen technology, the opportunities for innovation are vast. ICB factories are at the forefront of this wave, continuously pushing the limits of what is possible. One such innovation is the development of IoT (Internet of Things) enabled kitchen appliances that can communicate with each other and with the user’s mobile devices. This allows for remote monitoring and control, ensuring that the kitchen is always ready for the user’s return.

However, with great opportunity comes a set of challenges. One of the most significant challenges faced by ICB factories is the rapid pace of technological change. The industry is constantly evolving, and staying ahead of the curve requires significant investment in research and development. Additionally, the complexity of integrating multiple technologies into a single appliance can be daunting, requiring a high degree of precision and expertise.

Another challenge is the need for seamless integration between various brands and models. Consumers are increasingly looking for a cohesive smart kitchen ecosystem where all devices work together harmoniously. This requires ICB factories to collaborate closely with appliance manufacturers to ensure compatibility and interoperability.

Despite these challenges, the opportunities for growth and innovation in the smart kitchen industry are immense. As consumer demand for smart kitchen appliances continues to rise, so does the need for ICB factories to innovate and adapt. This is where the true potential of these factories lies – in their ability to anticipate future needs and deliver solutions that not only meet but exceed expectations.

In conclusion, the heart of the smart kitchen beats with the rhythm of innovation, powered by the relentless pursuit of excellence in ICB factories. These factories are not just manufacturers; they are architects of the future, crafting the building blocks of a kitchen that is intuitive, efficient, and responsive to the user’s every need. As we move forward, the collaboration between ICB factories and appliance manufacturers will continue to drive the smart kitchen revolution, transforming the way we live, cook, and interact with our homes.